LNG structure as well as nickel-based welding rod for marine 9Ni steel welding, and preparation method thereof

A nickel-based electrode, marine technology, applied in welding equipment, welding medium, welding/cutting medium/material, etc., can solve the problem of less application, and achieve the effect of small spatter, smooth weld bead and good manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

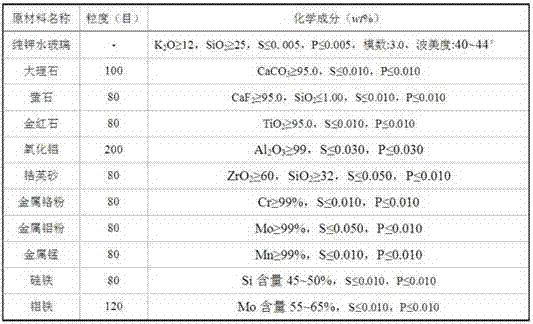

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of the nickel-based welding rod of LNG structure and marine 9Ni steel welding, comprises the following steps:

[0029] Step 1. Dosing according to the following components and percentages: C: ≤0.10%, Si: ≤0.10%, Mn: ≤0.10%, Cu: ≤0.10%, Mg: ≤0.10%, S≤0.005%, Fe: ≤0.40%, Ni+Co: ≥99.5%, after melting all the components, forging, rolling, drawing, and shredding, to obtain nickel-based welding core for use;

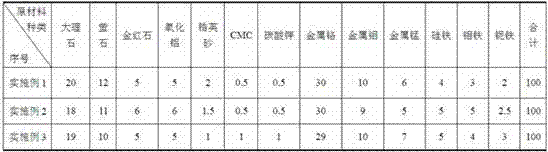

[0030] Step 2, according to the components and percentage content in Table 2 as the target ratio, calculate the marble, fluorite, rutile, α-Al to be added in Example 1 2 o 3 , zircon sand, carboxymethyl cellulose, potassium carbonate, metal chromium powder, metal molybdenum powder, metal manganese, ferrosilicon, ferromolybdenum, and ferroniobium, and weigh each material according to the calculation results; mix and dry mix evenly Finally, first add 2.5% water of the total weight of the material, pre-wet mix for 2~3 minutes, then add a binder wit...

Embodiment 2

[0032] The preparation method of the nickel-base welding rod of LNG structure and marine 9Ni steel welding, the preparation and chemical composition of welding core in step 1 are the same as embodiment 1, and the weight percentage content of coating powder is as shown in table 2; All the other features are the same as embodiment 1 .

Embodiment 3

[0034] The preparation method of the nickel-based welding rod of LNG structure and marine 9Ni steel welding, the preparation and chemical composition of welding core in step 1 are the same as embodiment 1 and embodiment 2, and the weight percentage content of coating powder is as shown in table 2; Other features With embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com