Magnesium alloy no-chromium passivant and use method

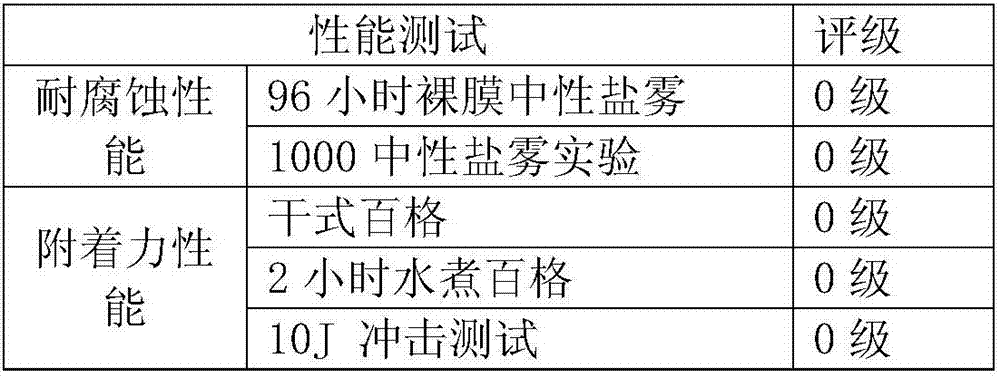

A chromium-free passivation agent and magnesium alloy technology, applied in the direction of metal material coating process, etc., can solve the problems of pollution, metal anti-corrosion protection performance coating adhesion performance can not achieve the effect of chromed products, large waste water and other problems. The effect of solving waste water pollution, excellent corrosion resistance of bare film and good adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with embodiment.

[0025] The invention provides a chromium-free passivator for magnesium alloys, the main components of which are zirconium / titanium-containing compounds and their derivatives, corrosion inhibitors, deionized water, at least one of silane coupling agents, nano Particles, at least one of thiourea.

[0026] The zirconium compound and its derivatives described in the present invention are one or a compound of fluozirconic acid / fluorotitanic acid / triethanolamine zirconate and other chemical compounds.

[0027] The titanium compound and derivatives thereof in the present invention are one or a combination of titanate chemicals such as diethanolamine diisopropyl titanate or triethanolamine diisopropyl titanate.

[0028] The corrosion inhibitor described in the present invention is one or a combination of triethanolamine, monoethanolamine, silane coupling agent and its derivatives, or thiour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com