Boron-doped silicon-based negative electrode material used for lithium ion battery

A silicon-based negative electrode material, lithium-ion battery technology, applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc., can solve the problem of not improving the electronic conductivity of silicon materials, and achieve follow-up processing methods Convenience, simple preparation process, natural and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Add 1g of boron trioxide and 10g of silicon nanowires into a mortar, grind to make the materials evenly dispersed, put the materials into a porcelain boat, put them into a tube furnace with nitrogen, and heat up at a rate of 5°C / min Sinter at 900°C for 1h. Cool to room temperature, immerse the material in sodium hydroxide solution for 0.5 h, wash with deionized water and dry to obtain a silicon-based negative electrode material (boron-doped silicon nanowire).

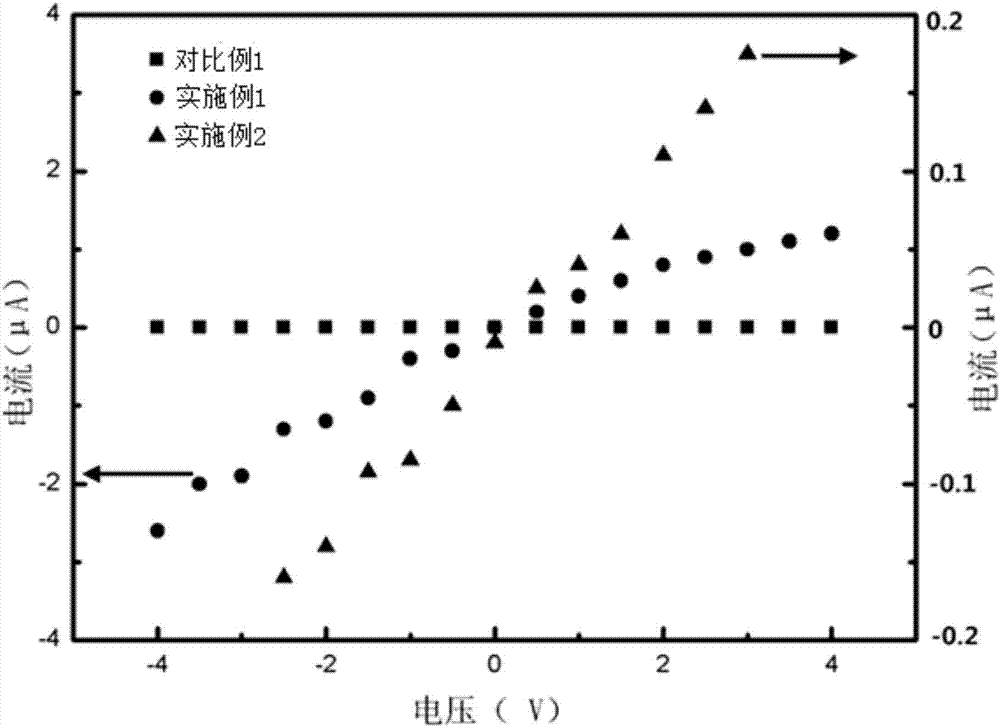

[0030] The electrochemical performance test of the silicon-based negative electrode material was carried out with a semiconductor characteristic analysis system using two probes, and its conductivity is shown in Table 1 and figure 1 shown. The electronic conductivity of the boron-doped silicon nanowire material after sintering at 900℃ for 1h is 5.2×10 -4 S / cm, so the silicon-based negative electrode material prepared by the present invention has improved electronic conductivity after being doped with boron.

Embodiment 2

[0034] Add 1g of boron trioxide and 10g of silicon nanowires into the mortar, grind the material to disperse evenly, put the material into a porcelain boat, put it into a tube furnace with nitrogen gas, and raise the temperature to 5°C / min. Sinter at 1000°C for 1h. Cool to room temperature, immerse the material in sodium hydroxide solution for 0.5 h, wash with deionized water and dry to obtain a silicon-based negative electrode material (boron-doped silicon nanowire).

[0035] The semiconductor characteristic analysis system uses two probes to test the electrochemical performance of the material, and its conductivity is shown in Table 1 and figure 1 shown. The electronic conductivity of boron-doped silicon nanowire material after sintering at 1000℃ for 1h is 0.21S / cm. By comparison, it can be found that the electronic conductivity of the material after boron doping is improved, and to a certain extent increases with the increase of temperature.

[0036] Table 1 Electronic c...

Embodiment 3

[0039] Add 1g of diboron trioxide and 10g of nano-silicon particles into the mortar, grind the material to disperse evenly, put the material into a porcelain boat, put it into a tube furnace with nitrogen, and raise the temperature to 1000 at a heating rate of 20°C / min. Sintering at ℃ for 1h. Cool to room temperature, soak the material in sodium hydroxide solution for 0.5 h, wash with deionized water and dry to obtain a silicon-based negative electrode material (boron-doped nano-silicon).

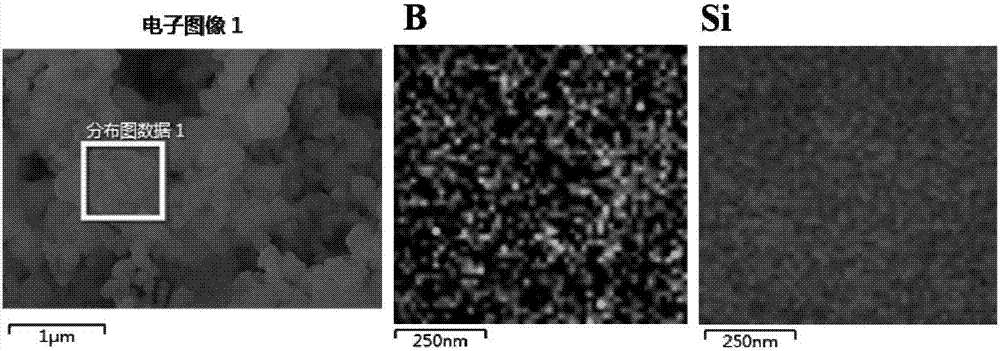

[0040] figure 2 According to the EDS energy spectrum, it can be found that there is obvious boron element in the material.

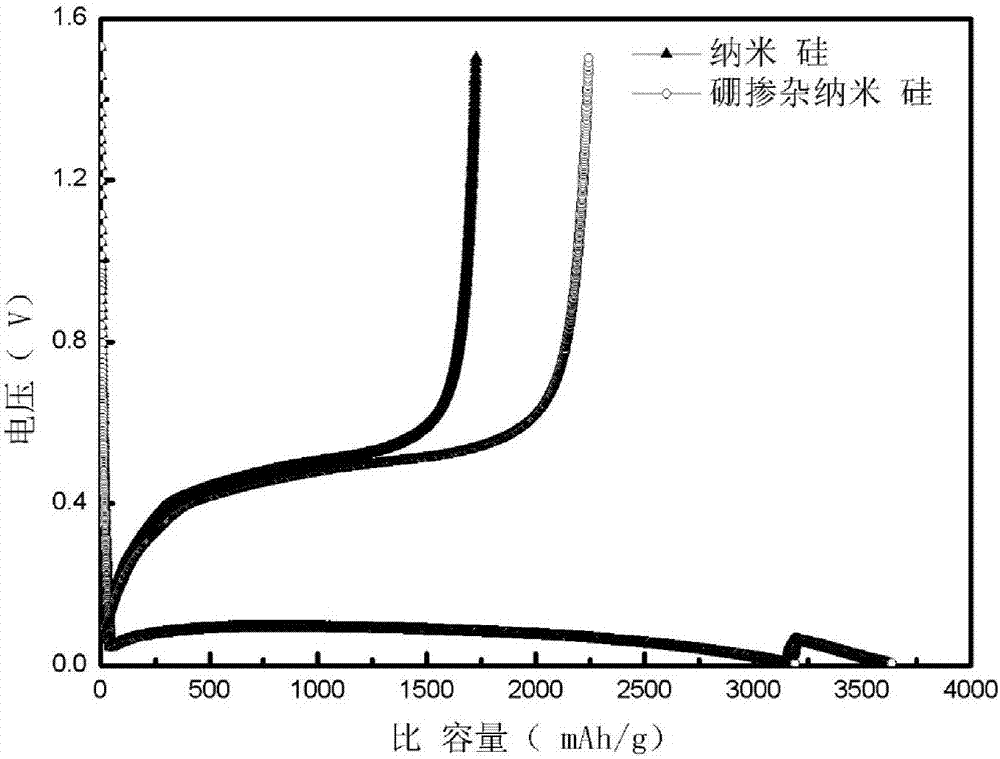

[0041] Nano-silicon: SP: LA133 = 8:1:1 ratio was mixed and coated, and CR2016 button cells were assembled. The electrolyte was EC+DMC solution with 1mol / L LiPF6, and the electrochemical performance was tested.

[0042] Such as image 3 Shown are the charge-discharge curves of nano-silicon and boron-doped nano-silicon, from image 3 It can be seen that the first cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electronic conductivity | aaaaa | aaaaa |

| Electronic conductivity | aaaaa | aaaaa |

| Electronic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com