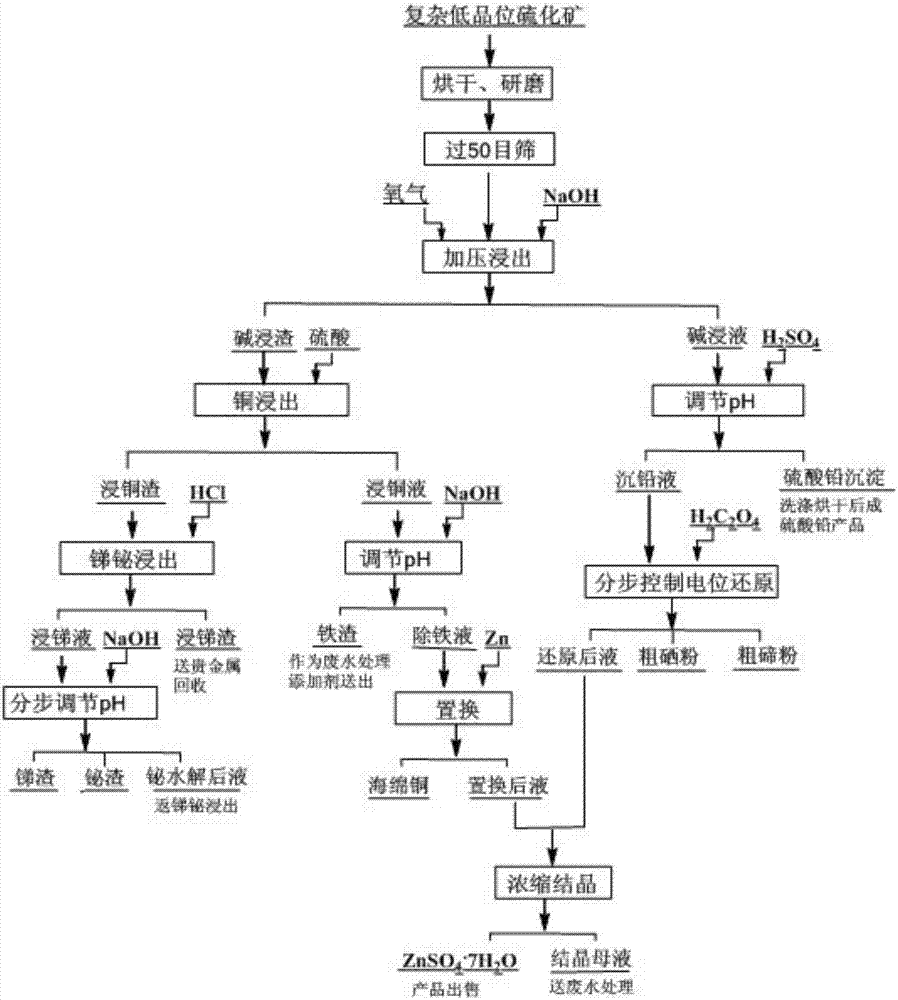

Process for all-wet recovery of valuable elements in complex low-grade sulphide ore

A valuable element, low-grade technology, applied in the direction of improving process efficiency, can solve the problems of small and medium-sized enterprises such as economic loss, incomplete metal separation, long process flow, etc., to achieve good treatment effect, low equipment investment requirements, and clean process. Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Take 300g of lead matte that has been crushed and ground through a 50-mesh sieve, mix it with 3.0L of 90g / L sodium hydroxide solution and pour it into a pressurized reaction kettle. After entering the oxygen pressure to 0.65MPa, the temperature was raised to 120°C, and the total pressure was 1.15MPa. After reacting for 3.0 hours, the kettle was discharged, and the alkali leaching solution and alkali leaching residue were obtained by filtration. Add sulfuric acid to the alkaline immersion solution to adjust the pH to 6, filter to obtain lead sulfate precipitation and lead sinking solution, wash the lead sulfate precipitate with dilute sulfuric acid and dry to obtain lead sulfate product, the lead recovery rate is 99.6%, and heat the lead sinking solution to 60°C , monitor the potential of the reaction solution while adding oxalic acid solid, stop adding oxalic acid when the potential of the reaction solution is 600mV, filter the coarse selenium powder and selenium-reduced...

Embodiment 2

[0030]Take 300g of copper-zinc mixed concentrate crushed and ground through a 50-mesh sieve, mix it with 2.4L of 110g / L sodium hydroxide solution and pour it into a pressurized reaction kettle. After the kettle body is installed, start stirring at a speed of 500r / min , filled with oxygen pressure to 0.85MPa, then heated to 135°C, the total pressure was 1.35MPa, reacted for 4.5h, unloaded the kettle, and filtered to obtain alkali leaching solution and alkali leaching residue. Add sulfuric acid to the alkaline immersion solution to adjust to pH = 3, filter to obtain lead sulfate precipitation and lead sinking solution, wash the lead sulfate precipitate with dilute sulfuric acid and dry to obtain lead sulfate product, heat the lead sinking solution to 70°C, and monitor while adding sodium sulfite Reaction solution potential, stop adding when the reaction solution potential is 550mV, filter to obtain coarse selenium powder and selenium-reduced solution, after selenium-reduction sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com