Polypropylene enhanced double-wall corrugated pipe

A polypropylene-reinforced, double-wall corrugated pipe technology, applied in hoses, pipes, rigid pipes, etc., can solve the problems of poor impact resistance, poor thermal stability, and high cost, and achieve improved impact resistance and elastic modulus , The effect of reducing the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

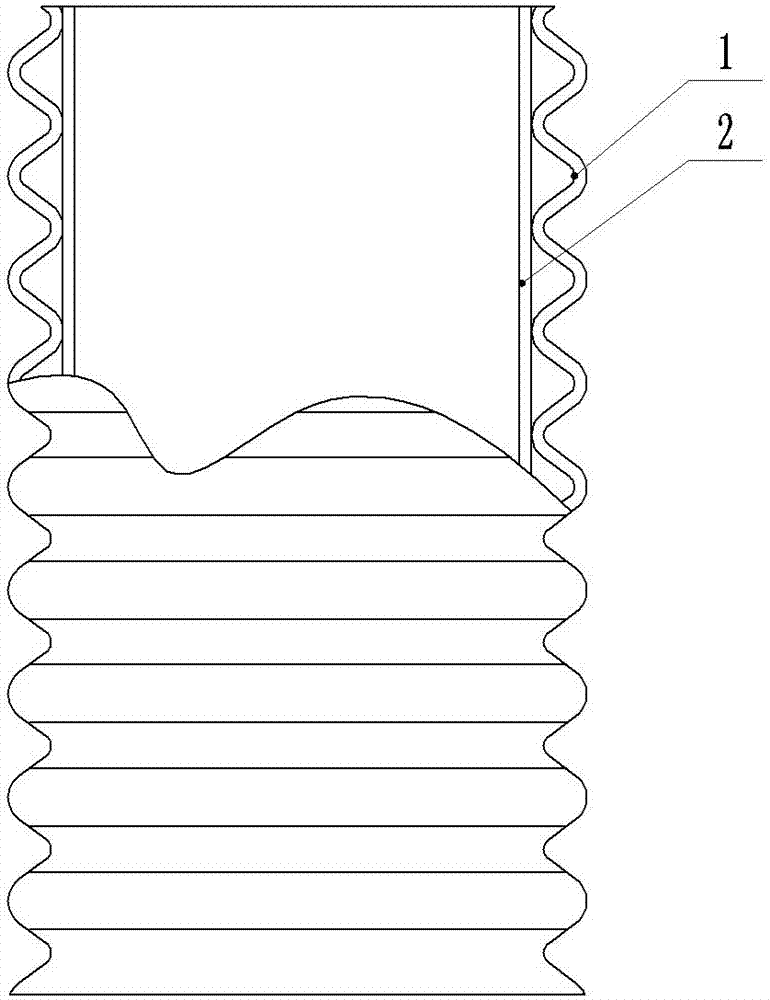

[0020] Such as figure 1 As shown, it includes a straight pipe layer 2 with a smooth inner wall and a corrugated outer pipe layer 1 with an annular structure, and the corrugated outer pipe layer is overcoated on the outer wall of the straight pipe layer.

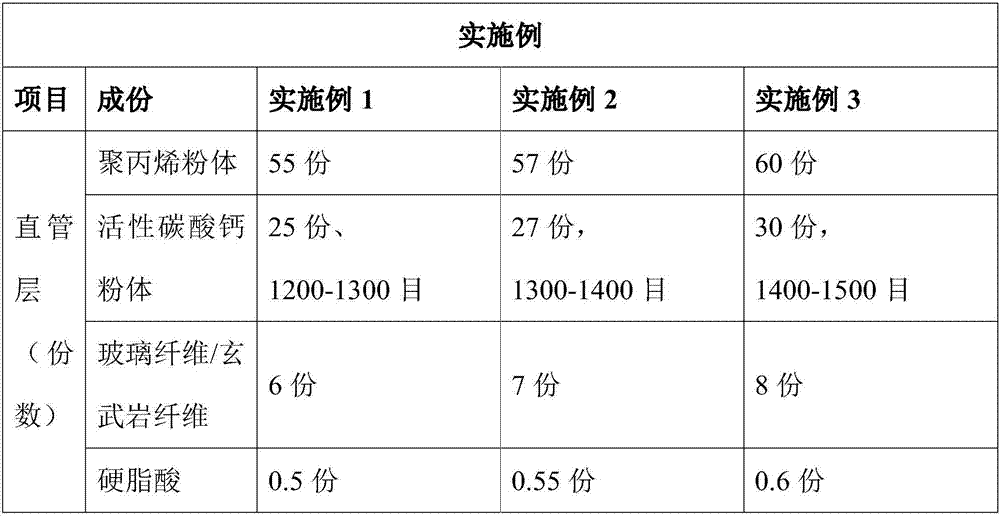

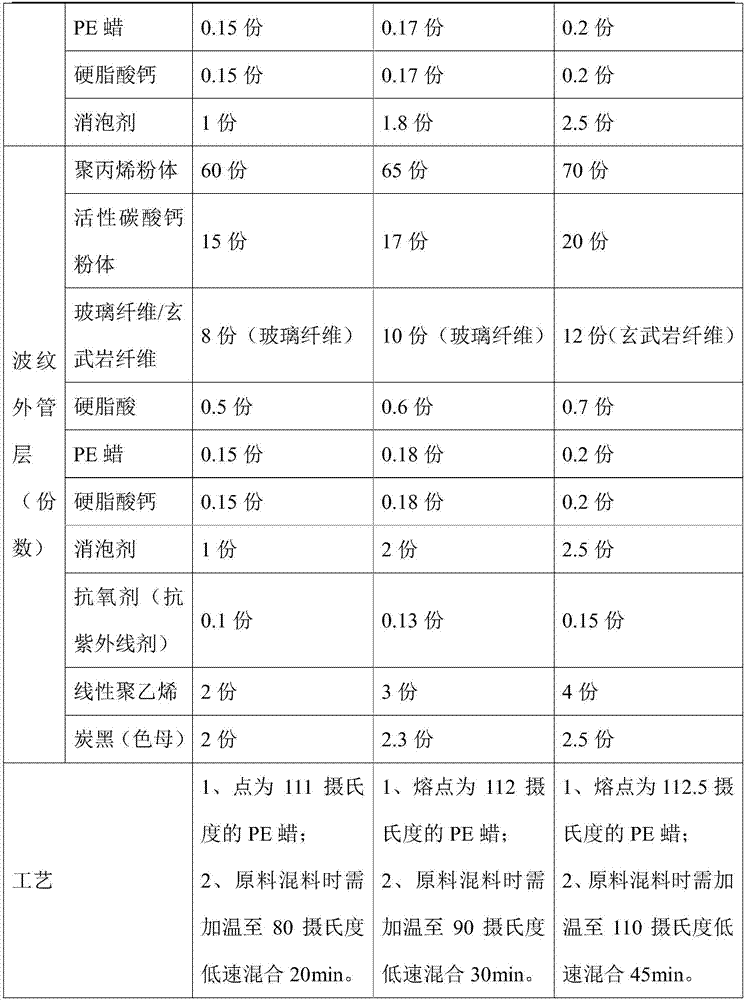

[0021] Straight tube layer components include: polypropylene powder, activated calcium carbonate powder, glass fiber, stearic acid, PE wax, calcium stearate, and defoamer;

[0022] Corrugated outer tube layer: polypropylene powder, activated calcium carbonate powder, glass fiber, stearic acid, PE wax, calcium stearate, defoamer, antioxidant (anti-ultraviolet agent), linear polyethylene and carbon black (Masterbatch).

[0023] Requirements for raw materials in the formula:

[0024] The polypropylene powder material is isotactic copolymerized polypropylene;

[0025] Calcium carbonate powder is a surface-activated powder above 1200 mesh;

[0026] The single glass fiber has a diameter of less than 15 microns and a length of 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com