Lithium titanate cathode material and preparation method thereof

A negative electrode material, lithium titanate technology, applied in nanotechnology for materials and surface science, battery electrodes, electrical components, etc., can solve the problem of affecting the electrochemical performance of lithium titanate negative electrode materials and cannot provide a stable coating layer structure Sexuality, inability to effectively isolate the nuclear structure and other issues, to achieve excellent ion transport performance, excellent electrochemical performance, and the effect of improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

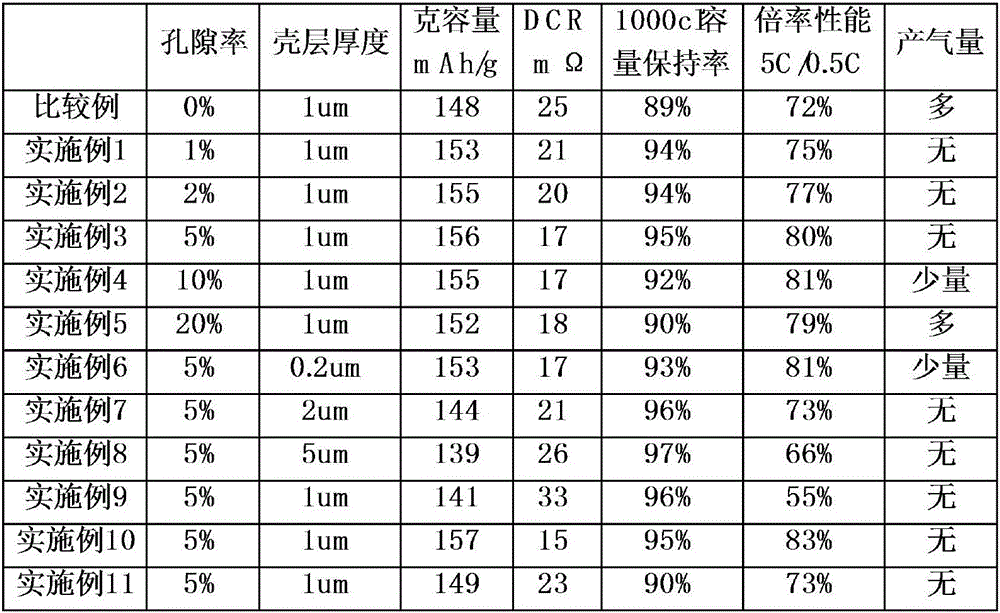

Examples

Embodiment 1

[0031] Embodiment 1, differs from comparative example in that this embodiment comprises the following steps:

[0032] Step 1. Preparation of nuclear structure: select lithium titanate particles of 100nm, and uniformly mix them with conductive agent components (the content of lithium titanate particles is 90%, and the conductive agent is Super P), and then spheroidize to obtain a particle diameter of about 12 μm. The secondary granular core structure is ready for use;

[0033] Step 2. Prepare coating layer slurry: mix asphalt, ammonium nitrate (ammonium nitrate accounts for 1% of solid content), and NMP to obtain coating layer slurry;

[0034] Step 3. Coating the slurry obtained in step 2 on the surface of the core structure in step 1, then heating and carbonizing, and removing the pore-forming agent in the coating layer at the same time, to obtain titanic acid with a shell structure layer porosity of 1% and a thickness of 1 μm Lithium anode material.

[0035] Others are the ...

Embodiment 2

[0036] Embodiment 2 is different from Embodiment 1 in that this embodiment includes the following steps:

[0037] Step 2. Prepare coating layer slurry: mix asphalt, ammonium nitrate (ammonium nitrate accounts for 2% of solid content), NMP, and obtain coating layer slurry;

[0038] Step 3. Coat the slurry obtained in step 2 on the surface of the core structure in step 1, then heat and carbonize, and remove the pore-forming agent in the coating layer at the same time to obtain titanic acid with a shell structure layer porosity of 2% and a thickness of 1 μm Lithium anode material.

[0039] Others are the same as in Example 1, and will not be repeated here.

Embodiment 3

[0040] Embodiment 3 is different from Embodiment 1 in that this embodiment includes the following steps:

[0041] Step 2. Prepare coating layer slurry: mix asphalt, ammonium nitrate (ammonium nitrate accounts for 5% of solid content), NMP, and obtain coating layer slurry;

[0042] Step 3. Coat the slurry obtained in step 2 on the surface of the core structure in step 1, then heat and carbonize, and remove the pore-forming agent in the coating layer at the same time to obtain titanic acid with a shell structure layer porosity of 5% and a thickness of 1 μm Lithium anode material.

[0043] Others are the same as in Example 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com