A kind of preparation method of double-layer electrode and its application

A double-layer electrode, hydrofluoric acid technology, applied in the field of environmental pollution treatment technology and material chemistry, to achieve the effect of improving electron transfer efficiency, improving photoelectric catalytic activity, and improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A double-layer D-{001}TiO 2 The preparation method of / Ti electrode specifically comprises the following steps:

[0027] (1) Under magnetic stirring, hydrofluoric acid (HF) was added dropwise to isopropyl titanate, and anatase {001}TiO was obtained by hydrothermal method 2 nanoparticles.

[0028] (2) At room temperature, mix absolute ethanol, tetrabutyl titanate, and concentrated nitric acid, stir vigorously, and let stand to form light yellow transparent TiO 2 Sol. The surface of the pure metal titanium sheet is polished, polished, cleaned and etched with metallographic sandpaper, fixed vertically on the pulling dipping machine, and the Ti base electrode is immersed in the TiO 2In the sol, pull and dip for 1 to 3 times at a speed of 1-2mm / min, and after natural drying, place it in a tube furnace for heat treatment with a temperature increase of 0.7°C / min-2°C / min Raise the temperature to 450°C-550°C for 30-60 minutes to obtain dense TiO 2 Oxide film conductive layer...

Embodiment 2

[0031] Comparative electrode S-{001}TiO 2 / Ti was prepared according to the method of Example 1. After the Ti plate was etched, the prepared {001}TiO 2 nanoparticles.

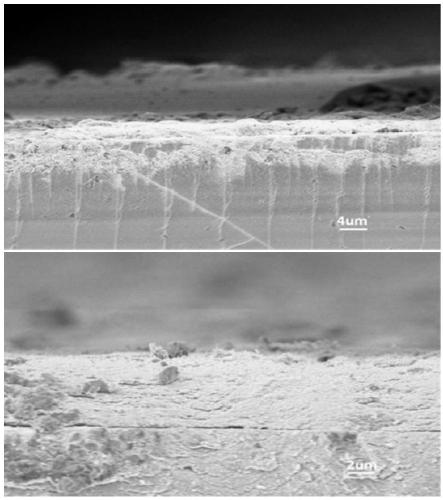

[0032] The prepared D-{001}TiO 2 / Ti electrode and S-{001}TiO 2 / Ti electrodes were characterized by field emission scanning electron microscopy, by figure 1 It can be observed that for D-{001}TiO 2 The TiO present between the / Ti electrode and the substrate electrode 2 The conductive layer of the oxide film is closely combined with the substrate, but for S-{001}TiO 2 / Ti electrode and its deposited {001}TiO 2 layer due to {001}TiO 2 There are gaps between the stacks of nanoparticles and a certain gap between them and the substrate electrode, which hinders the transport of electrons on the electrodes.

Embodiment 3

[0034] D-{001}TiO 2 / Ti electrode and contrast electrode photoelectrochemical measurement, concrete steps comprise as follows:

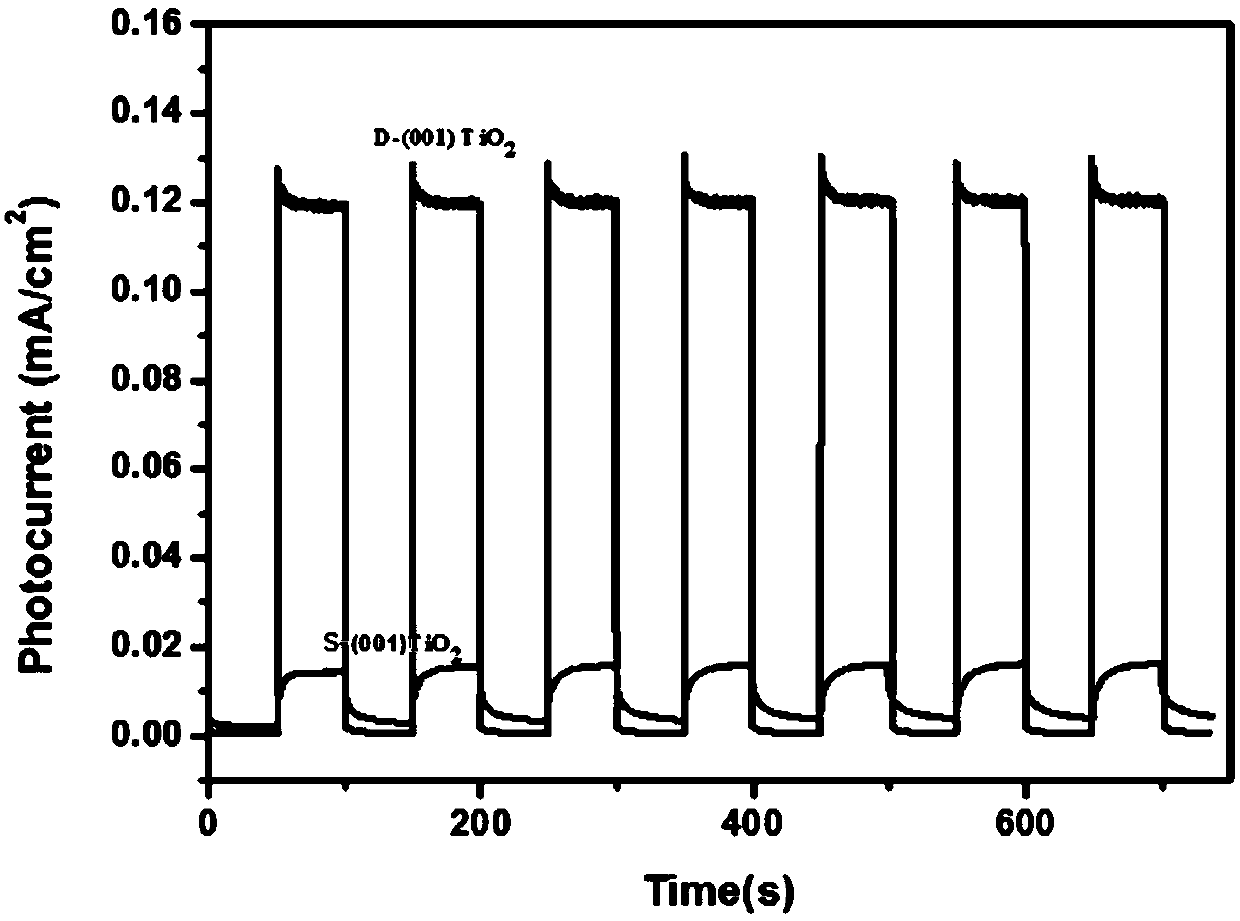

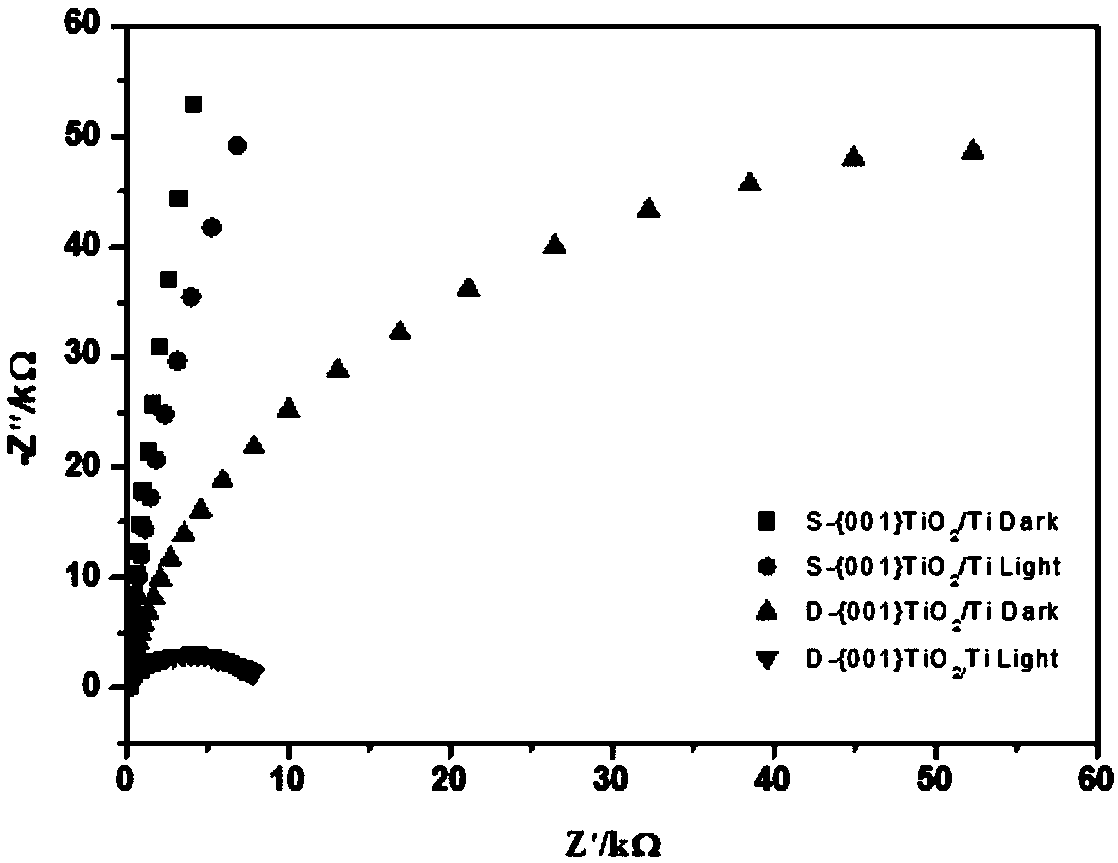

[0035] D-{001}TiO on CHI660c electrochemical workstation 2 / Ti and S-{001}TiO 2 / Ti electrode for photoelectrochemical performance test, the control electrode area is 0.5cm 2 , the device used is a three-electrode system electrochemical reaction cell with a quartz window, with a saturated calomel electrode (SCE) as the reference electrode, a Pt wire electrode as the counter electrode, and a 0.1mol L -1 Na 2 SO 4 The solution is an electrolyte. With 300W LA-410UV as the light source, apply a bias voltage of 0.4V, and measure its i-t curve. At the same time, at the open circuit potential, D-{001}TiO 2 / Ti and S-{001}TiO 2 AC impedance plots of the / Ti electrode under non-illuminated and illuminated conditions. Such as figure 2 As shown, D-{001}TiO 2 / Ti photocurrent is S-{001}TiO 2 / Ti photocurrent response value 8 times. Such as image ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| catalytic efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com