Low-temperature negative pressure ammonia removal system device based on fluid-jet flow principle

A low-temperature negative pressure, fluid jet technology, applied in degassed water/sewage treatment, neutralized water/sewage treatment, water/sludge/sewage treatment, etc., can solve high energy consumption, large fluctuations in ammonia nitrogen wastewater quality, and system operation Negative pressure control instability and other problems, to achieve the effect of increasing the temperature of the reflux liquid, reducing the impact of system negative pressure, and saving steam consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

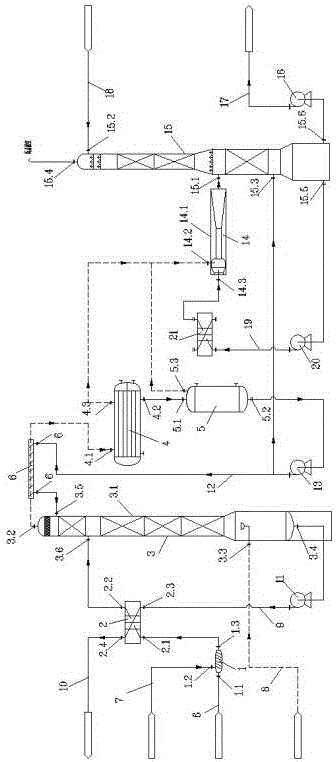

[0013] Embodiment 1: A low-temperature negative pressure deamination system device based on the fluid jet principle, comprising a pipeline mixer 1, a preheater 2, a low-temperature deamination tower 3, a condenser 4, and a gas-liquid separation tank 5, and ammonia nitrogen-containing wastewater enters The water pipeline 6 is connected to the pipeline mixer inlet 1.1, the pH regulator feed pipeline 7 is connected to the pipeline mixer dosing port 1.2, the pipeline mixer outlet 1.3 is connected to the first inlet 2.1 of the preheater, and the low-temperature deamination tower 3 includes a tower body 3.1, The feed inlet 3.6 that is arranged on the top of the tower body 3.1, the gas outlet 3.2 that is arranged on the top of the tower body 3.1, the steam inlet 3.3 that is arranged on the bottom end of the tower body 3.1, the deammonized water outlet 3.4 that is arranged on the bottom end of the tower body 3.1 and is arranged on The reflux liquid inlet 3.5 near the top of the tower b...

Embodiment 2

[0014] Embodiment 2: With reference to Embodiment 1, other characteristics remain unchanged, a heat exchanger 22 is arranged between the gas inlet 4.1 of the condenser and the gas outlet 3.2 of the low-temperature deamination tower, and the reflux liquid circulation pipeline 12 passes through the heat exchanger 22 after exchanging heat. Connect the reflux inlet 3.5 of the low-temperature deamination tower.

[0015] Ammonia-nitrogen-containing wastewater is added with a pH regulator through the pipeline mixer to adjust the pH of the wastewater to be alkaline. After heat exchange between the preheater and the tower kettle outlet water, it enters the negative pressure deammonization tower, and countercurrently contacts with the steam in the tower. The steam and the ammonia-containing wastewater Wastewater undergoes mass transfer and heat transfer in the tower. When the ammonia-containing wastewater reaches the bottom of the tower, the ammonia nitrogen is converted into ammonia gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com