Halomonas taeanensis for degradation of phenol

A Halomonas, phenol technology, applied in the direction of bacteria, microorganism-based methods, water/sludge/sewage treatment, etc., to achieve good salt resistance effect, good economic value and application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The isolation and identification of embodiment 1 Halomonas H17

[0024] 1. Isolation of Halomonas H17

[0025] a. Dissolve 1-5g of collected solid samples (salt lake sludge, submarine sludge, high-salt wastewater treatment sludge, etc.) or 500ml of liquid samples (salt lake water, seawater, high-salt wastewater, etc.) in 10-50ml Liquid medium (10g MgSO 4 ·7H 2 O, 0.2g CaCl 2 2H 2 O, 2-5g KCl, 2.5g tryptone, 10g yeast extract, NaCl15%, distilled water were added to 1000ml. Adjust the pH to about 7.2, sterilize at 121°C for 15 minutes), shake at 80-160 rpm for 30-120 minutes at room temperature, take it out and let it stand for 20-40 minutes, draw 100 μL with a pipette, and spread evenly on the solid medium for culture Place on a flat plate (obtained by adding 2% agar to the above-mentioned liquid medium), and place it in a constant temperature incubator at 28°C for static culture.

[0026] b. When visible colonies are grown, use an inoculation loop to pick a single...

Embodiment 2

[0036] The performance test of the degradation phenol of embodiment 2 Halomonas H17

[0037] The degradation of phenol in the medium by Halomonas H17 was detected by high performance liquid chromatography.

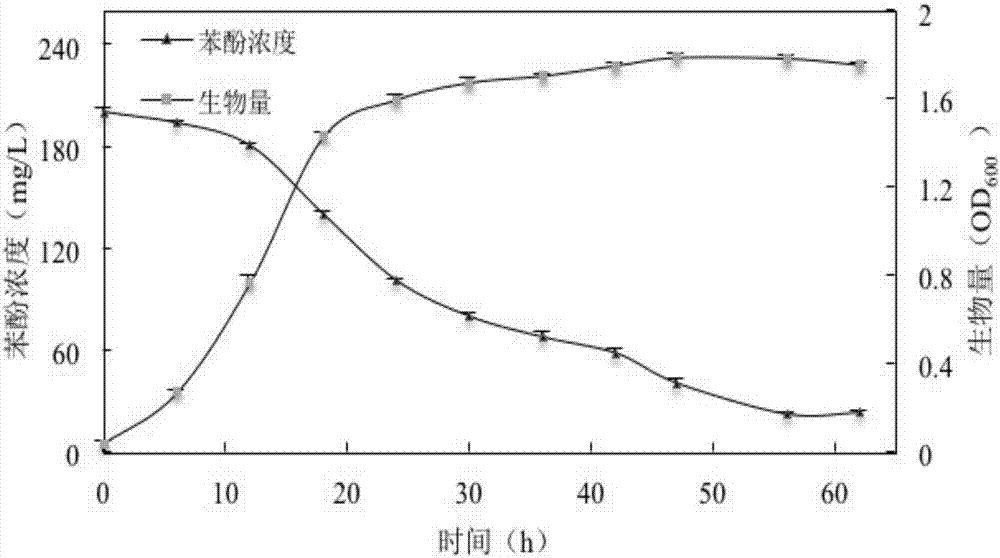

[0038] 1. Growth of strain H17 and characteristics of phenol degradation

[0039] Bacterial strain H17 is 200mg / L in phenol concentration, and the medium that sodium chloride concentration is 10%, the formula of described medium 1L is 10g MgSO 4 ·7H 2 O, 0.2g CaCl 2 2H 2 O, 2-5g KCl, 2.5g tryptone, 10g yeast extract, NaCl10%, distilled water were added to 1000ml. Adjust the pH to about 7.2, and sterilize at 121°C for 15 minutes.

[0040] The curves of strain growth and phenol concentration changes over time in the medium are as follows: figure 2shown. Strain H17 entered the logarithmic growth phase after a stagnation period of about 8 hours. During this period, the strain grew almost linearly with time, and the strain was in a stable growth period near 30 hours and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com