Profile-control and water-plugging agent and profile-control and water-plugging method used for profile control and water plugging of high-temperature and high-salinity oil reservoir

A technology of profile control, water plugging and high salinity, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of poor temperature and salt resistance of plugging agents, and achieve high plugging strength and long-term The effect of stability and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

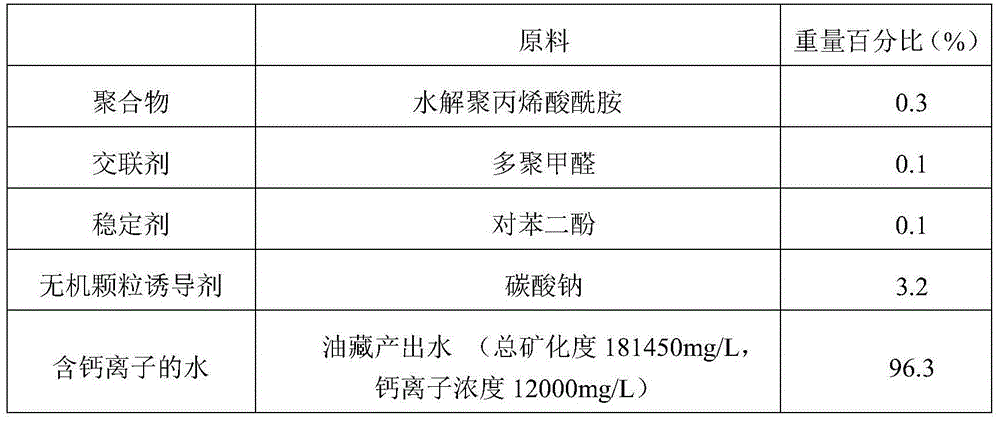

[0049] The raw material formula of plugging agent is as follows:

[0050]

[0051] The plugging agent preparation process is as follows:

[0052] Add hydrolyzed polyacrylamide to the above-mentioned calcium ion-containing water while stirring, and obtain a polymer solution after aging; add a crosslinking agent and a stabilizer to the polymer solution while stirring, and form a transition solution after being dissolved; finally, add a transition solution to the transition solution Add inorganic particle inducer to form a mixed solution;

[0053] The above mixed solution is subjected to a cross-linking reaction at a temperature of 120°C to form an organic / inorganic composite gel, that is, to form a plugging agent.

[0054] The above-mentioned plugging agent was kept at 120°C for 60 days, and the colloid did not dehydrate, and the viscosity retention rate was 75.5%.

Embodiment 2

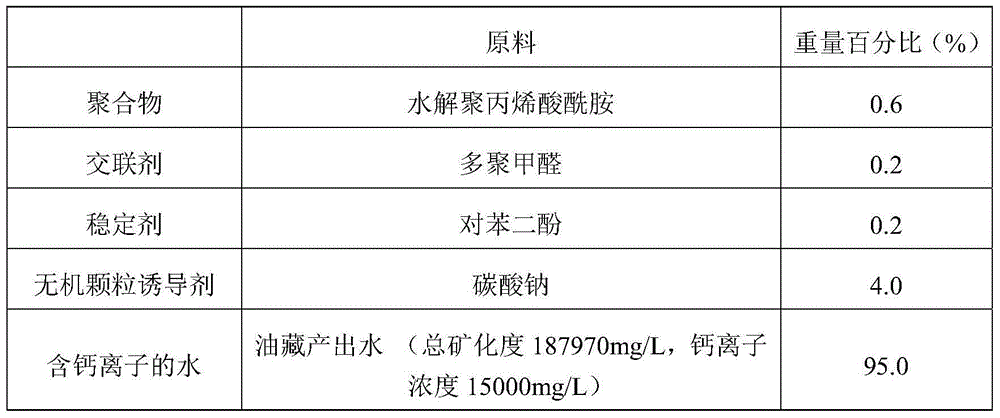

[0056] The raw material formula of plugging agent is as follows:

[0057]

[0058] The plugging agent preparation process is as follows:

[0059] Add hydrolyzed polyacrylamide to the above-mentioned calcium ion-containing water while stirring, and obtain a polymer solution after aging; add a crosslinking agent and a stabilizer to the polymer solution while stirring, and form a transition solution after being dissolved; finally, add a transition solution to the transition solution Add inorganic particle inducer to form a mixed solution;

[0060] The above mixed solution is subjected to a cross-linking reaction at a temperature of 120°C to form an organic / inorganic composite gel, that is, to form a plugging agent.

[0061] The above-mentioned plugging agent was kept at 120°C for 60 days, and the colloid did not dehydrate, and the viscosity retention rate was 87.0%.

Embodiment 3

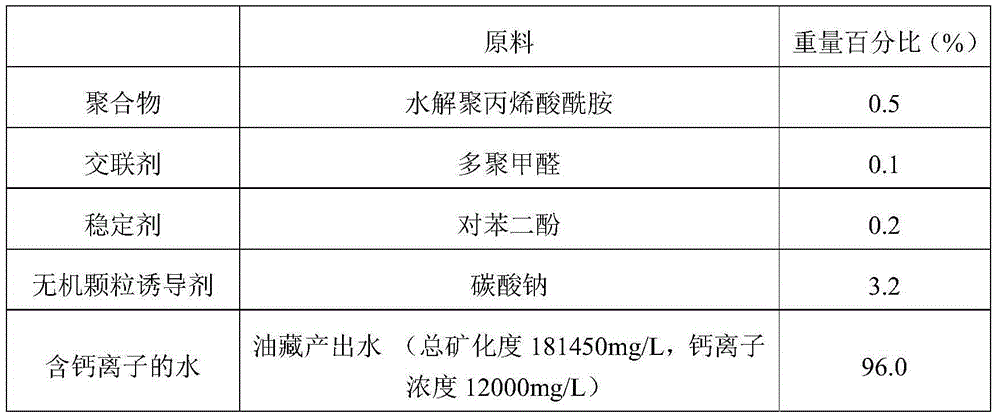

[0063] The raw material formula of plugging agent is as follows:

[0064]

[0065] The plugging agent preparation process is as follows:

[0066] Add hydrolyzed polyacrylamide to the above-mentioned calcium ion-containing water while stirring, and obtain a polymer solution after aging; add a crosslinking agent and a stabilizer to the polymer solution while stirring, and form a transition solution after being dissolved; finally, add a transition solution to the transition solution Add inorganic particle inducer to form a mixed solution;

[0067] The above mixed solution is subjected to a cross-linking reaction at a temperature of 120°C to form an organic / inorganic composite gel, that is, to form a plugging agent.

[0068] The above-mentioned plugging agent was kept at 120°C for 60 days, and the colloid did not dehydrate, and the viscosity retention rate was 80.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| core plugging rate | aaaaa | aaaaa |

| core plugging rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com