Liquid thickening agent system and application thereof

A liquid thickener and system technology, which is applied in the fields of production fluids, chemical instruments and methods, wellbore/well components, etc., can solve the problems of inability to complete the construction, affecting the fracturing effect, insufficient preparation of raw glue, etc. Small space, meet the needs of seawater fracturing, and make up for the lack of offshore fracturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

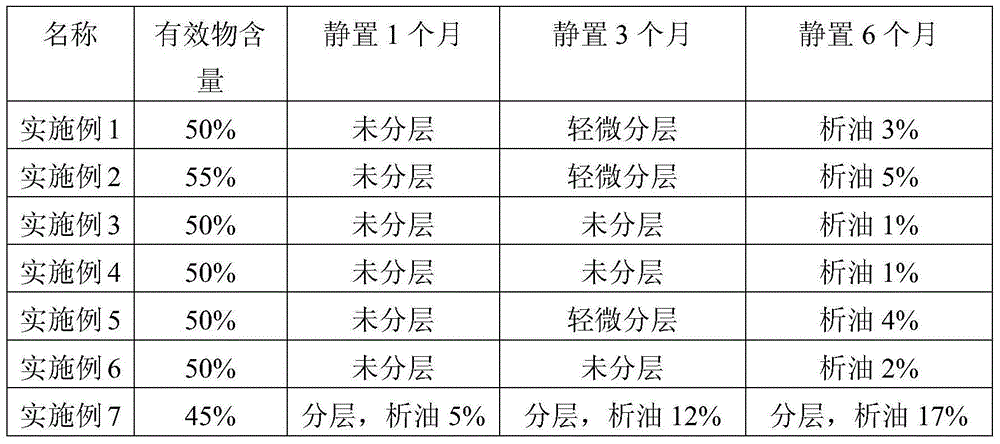

Examples

Embodiment 1

[0026] Pour 40g of white oil into the container, add 50g of hydroxypropyl guar gum, 2g of chloroform-acetone (1:3 volume ratio mixed solution), and 801g of Span-801g while stirring. Take 8.3g of distilled water, dissolve 0.1g of cetyltrimethylammonium bromide (CTAB) under stirring, and slowly add 0.1g of polyester fiber under rapid stirring after the dissolution is complete. The prepared aqueous solution is slowly poured into the organic solution in a stirring state to complete the preparation of a liquid hydroxypropyl guar gum system with an active substance content of 50%. The 170s-viscosity measured with a six-speed viscometer at room temperature is 78mPa·s. Prepare 0.5% hydroxypropyl guar gum solution: take 100ml of tap water and add 1% liquid hydroxypropyl guar gum system, stir at 800r / min for 3 minutes, measure 170s with a six-speed viscometer--viscosity is 193mPa s; Add 1ml of liquid hydroxypropyl guar gum system to 100ml of artificial seawater, stir at 800r / min for 3 ...

Embodiment 2

[0028] Take 35g of white oil and pour it into the container, add 55g of hydroxypropyl guar gum, 1g of chloroform-acetone (1:3 volume ratio mixed solution) and 1.5g of Span-80 while stirring. Take 7.3g of distilled water, dissolve 0.1g of CTAB under stirring, and slowly add 0.1g of polyester fiber under rapid stirring after the dissolution is complete. Slowly pour the prepared aqueous solution into the organic solution in a stirring state to complete the preparation of a liquid hydroxypropyl guar gum system with an active matter content of 55%. Use a room temperature six-speed viscometer to measure 170s-the viscosity is 85mPa s; prepare a hydroxypropyl guar gum solution with a concentration of about 0.5%: take 100ml of a certain amount of tap water and add 1g of liquid hydroxypropyl guar gum system, 800r / min Stir for 3 minutes, measure 170s with a six-speed viscometer - the viscosity is 231mPa s; take 100ml of artificial seawater, add 1g of liquid hydroxypropyl guar gum system,...

Embodiment 3

[0030]Weigh 35g of white oil and pour it into a container, add 50g of hydroxypropyl guar gum, 2g of chloroform-acetone (1:3 volume ratio mixed solution), and 1.5g of Span-80 while stirring. Take 10.5g of distilled water and dissolve 0.5g of CTAB under stirring. After the dissolution is complete, slowly add 0.5g of polyester fiber under rapid stirring. Slowly pour the prepared aqueous solution into the organic solution in a stirring state to complete the preparation of a liquid hydroxypropyl guar gum system with an active matter content of 55%. Measured with a room temperature six-speed viscometer at 170s-viscosity is 56mPa s; Take 100ml of tap water and add 1g liquid hydroxypropyl guar gum system, stir at 800r / min for 3 minutes, six-speed viscometer measures 170s-viscosity is 201mPa s; Take 100ml of artificial seawater, add 1g of liquid hydroxypropyl guar gum system, stir at 800r / min for 3 minutes, measure 170s with a six-speed viscometer - the viscosity is 209mPa·s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com