Cationic aqueous hydroxy acrylic resin secondary dispersion and preparation method thereof

A technology of hydroxyacrylic acid and secondary dispersion, which is applied in the direction of antifouling/underwater coatings, coatings, paints containing biocides, etc., and can solve the problems of adhesion, alkali resistance sealing, shielding and anti-stain penetration. Meet other problems, achieve the effect of small particle size, good fluidity, and improve adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

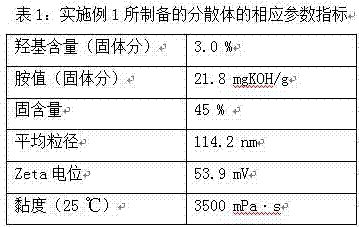

Embodiment 1

[0055] This example aims to demonstrate cationic waterborne hydroxyacrylic resin secondary dispersion and its preparation method, as follows:

[0056] Ethylene glycol monobutyl ether 18 g, 100 # Add 18 g of solvent naphtha and 1 g of di-tert-butyl peroxide into the reaction vessel, blow nitrogen, stir and heat up to 145 °C, and keep it warm for 15 min; add 32 g of methyl methacrylate, 46 g of n-butyl acrylate, and hydroxy A mixture of 29.2 g of ethyl ester, 12.8 g of styrene, 0.96 g of α-methylstyrene dimer and 4.8 g of di-tert-butyl peroxide was dropped into the reaction vessel at a constant speed, and the dripping was completed within 1.5 h, and the temperature was continued for 10 min; 18 g of methyl methacrylate, 26 g of n-butyl acrylate, 16.8 g of hydroxyethyl methacrylate, 7.2 g of styrene, 12 g of dimethylaminoethyl methacrylate and 3.2 g of di-tert-butyl peroxide Add g of the mixture into the reaction vessel at a uniform speed, control the dripping within 1 h, and con...

Embodiment 2

[0059] Compared with Example 1, this example aims to demonstrate the cationic waterborne hydroxyl acrylic resin secondary dispersions with different contents of tertiary amino group-containing acrylic monomers and their preparation methods.

[0060] Ethylene glycol monobutyl ether 18 g, 100 # Add 18 g of solvent naphtha and 1 g of di-tert-butyl peroxide into the reaction vessel, blow nitrogen, stir and raise the temperature to 145 °C, and keep it warm for 15 min; add 31.8 g of methyl methacrylate, 45.6 g of n-butyl acrylate, and hydroxy A mixture of 29 g of ethyl ester, 12.6 g of styrene, 0.96 g of α-methylstyrene dimer and 4.8 g of di-tert-butyl peroxide was dropped into the reaction vessel at a constant speed, and the dripping was completed within 1.5 h, and the temperature was continued for 10 min; 18.6 g of methyl methacrylate, 26.6 g of n-butyl acrylate, 17 g of hydroxyethyl methacrylate, 7.4 g of styrene, 10.4 g of dimethylaminoethyl methacrylate and di-tert-butyl peroxi...

Embodiment 3

[0063] Compared with Example 1, this example aims to demonstrate the different M 1 / M 2 Proportional cationic waterborne hydroxyacrylic resin secondary dispersion and preparation method thereof.

[0064] Ethylene glycol monobutyl ether 18 g, 100 # Add 18 g of solvent naphtha and 1 g of di-tert-butyl peroxide into the reaction vessel, blow nitrogen gas, stir and heat up to 145 °C, and keep it warm for 15 min; add 40.2 g of methyl methacrylate, 52.2 g of n-butyl acrylate, hydroxymethacrylate A mixture of 31.6 g of ethyl ester, 14.9 g of styrene, 1.12 g of α-methylstyrene dimer and 5.6 g of di-tert-butyl peroxide was dropped into the reaction vessel at a constant speed, and the dripping was completed within 1.5 h. Insulate for 10 min; add 14 g of methyl methacrylate, 18.3 g of n-butyl acrylate, 10.6 g of hydroxyethyl methacrylate, 5.1 g of styrene, 12 g of dimethylaminoethyl methacrylate and ditertiary peroxide Add 2.4 g of butyl mixture into the reaction vessel at a constant ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com