Alkali-activated slag cement efflorescence inhibitor and preparation method thereof

A technology of alkali slag cement and pan-alkali inhibitor, which is applied in the field of building materials, can solve the problems of quality accidents, prolong the delivery time, rework, etc., and achieve the effects of low cost of use, improvement of project quality, and reduction of amplitude.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

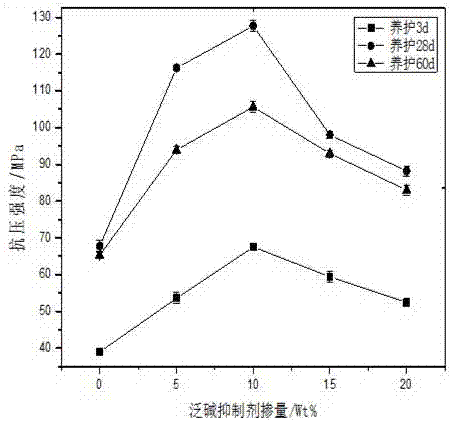

[0030] Weigh 10kg of 5A zeolite, 20kg of silica fume, 25kg of high-calcium fly ash, 35kg of ultrafine slag powder, and 10kg of industrial grade boric acid, and fully mix the above raw materials in a mixer for 10 hours to ensure that they are fully mixed. The material was ground in a ball mill for 8 hours, and its specific surface area was determined to be 550m 2 / kg, the ubiquitin inhibitor was obtained. as attached figure 1 As shown, with the increase of the amount of efflorescence inhibitor in Example 1, the strength of alkali slag cement showed a trend of first increasing and then decreasing. The optimal dosage of ubiquitine inhibitor was 10.0%, and the compressive strength was increased compared with that without ubiquitine inhibitor.

Embodiment 2

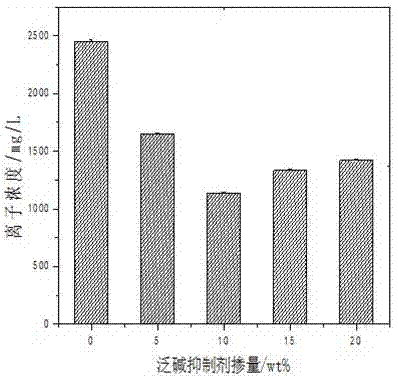

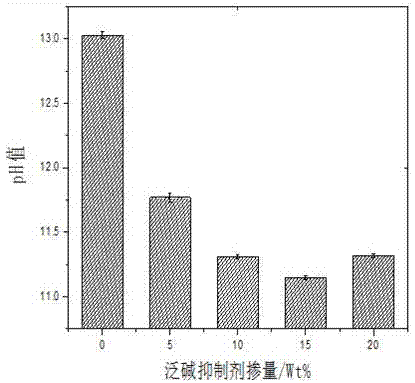

[0032] Weigh 15kg of 5A zeolite, 20kg of silica fume, 20kg of fly ash, 40kg of superfine slag powder, and 5kg of industrial-grade boric acid, and fully mix the above raw materials in a mixer for 10 hours to ensure that they are fully mixed. Grind in a ball mill for 7 hours, and measure its specific surface area to be 520m 2 / kg, the ubiquitin inhibitor was obtained. From attached figure 2 It can be seen that after adding the efflorescence inhibitor, the concentration of carbonate ions (ie, the main component of efflorescence) in the surface layer of the hardened slurry of alkali slag cement dropped sharply, from 2500 mg / L to 1100 mg / L, effectively inhibiting the efflorescence phenomenon of alkali slag cement . From attached image 3 It can be seen that after adding the pan-alkaline inhibitor, the pH value of the alkali slag hardened slurry is significantly reduced, but it still maintains an alkaline environment above 11.0. Therefore, the pan-alkaline inhibitor can adjust t...

Embodiment 3

[0034] Weigh 20kg of 5A zeolite, 20kg of silica fume, 20kg of high-calcium fly ash, 25kg of ultrafine slag powder, and 15kg of industrial grade boric acid, and fully mix the above raw materials in a mixer for 12 hours to ensure that they are fully mixed. The material was ground in a ball mill for 9 hours, and its specific surface area was determined to be 580m 2 / kg, the ubiquitin inhibitor was obtained. From attached Figure 4 It can be seen that the pore size of the alkali slag cement hardened slurry decreases from harmful pores greater than 0.02um to harmless pores less than 0.02um after adding the tripubtine inhibitor of the example. It reduces the probability of efflorescence caused by alkali ions passing through the open channel with the increase of water, thereby inhibiting the efflorescence phenomenon of alkali slag cement. From attached Figure 5 It can be seen that the water absorption of the alkali slag cement hardened slurry after adding the efflorescence inhibi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com