Method for preparing mesoporous silicon nanoparticle coating loaded with heparin and Cu<2+> on surface of biological material

A technology of nanoparticles and biomaterials, applied in coatings, drug delivery, pharmaceutical formulations, etc., can solve the problem that the fixed amount of heparin on the surface is difficult to ensure the long-term sustained effect of implanted materials in blood vessels, and it is difficult to ensure the sustained and controlled release of heparin. Its activity and other issues can achieve good blood compatibility, improve the success rate of implantation, and improve the effect of biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

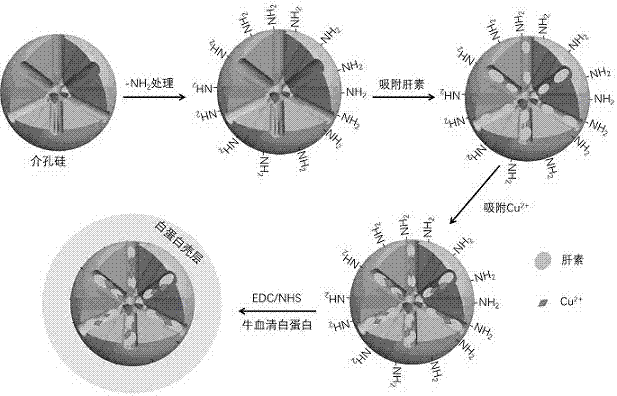

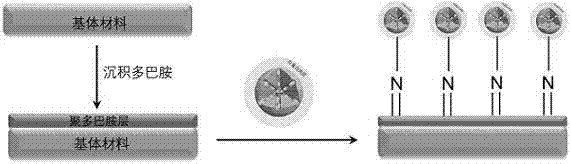

[0046] Preparation of heparin and Cu on the surface of biomaterials 2+ A method for coating mesoporous silicon nanoparticles, comprising the steps of:

[0047] 1) Firstly, the surface of mesoporous silicon nanoparticles is modified to obtain MSN-NH 2 ;

[0048] 2) Then load heparin and Cu in the mesoporous channels 2+ ;

[0049] 3) Then modify the surface of nanoparticles with albumin;

[0050] 4) Finally, the nanoparticles were immobilized on the surface of dopamine-modified biomaterials to obtain MSN-NH 2 Coating of @He / Cu.

[0051] In the step 1), the surface modification method of mesoporous silicon nanoparticles is as follows:

[0052] 1.1) Fully mix mesoporous silicon nanoparticles and aminosilane molecular solution;

[0053] 1.2) Shake the reaction for 30 hours, and collect the nanoparticles by centrifugation;

[0054] 1.3) Wash with ethanol three times;

[0055] 1.4) MSN-NH was obtained after vacuum drying at 80 degrees Celsius 2 .

[0056] In the step 1.1),...

Embodiment 2

[0074] Preparation of heparin and Cu on the surface of biomaterials 2+ A method for coating mesoporous silicon nanoparticles, comprising the steps of:

[0075] 1) Firstly, the surface of mesoporous silicon nanoparticles is modified to obtain MSN-NH 2 ;

[0076] 2) Then load heparin and Cu in the mesoporous channels 2+ ;

[0077] 3) Then modify the surface of nanoparticles with albumin;

[0078] 4) Finally, the nanoparticles were immobilized on the surface of dopamine-modified biomaterials to obtain MSN-NH 2 Coating of @He / Cu.

[0079] In the step 1), the surface modification method of mesoporous silicon nanoparticles is as follows:

[0080] 1.1) Fully mix mesoporous silicon nanoparticles and aminosilane molecular solution;

[0081] 1.2) Shake the reaction for 30 hours, and collect the nanoparticles by centrifugation;

[0082] 1.3) Wash with ethanol three times;

[0083] 1.4) MSN-NH was obtained after vacuum drying at 80 degrees Celsius 2 .

[0084] In the step 1.1),...

Embodiment 3

[0102] Preparation of heparin and Cu on the surface of biomaterials 2+ A method for coating mesoporous silicon nanoparticles, comprising the steps of:

[0103] 1) Firstly, the surface of mesoporous silicon nanoparticles is modified to obtain MSN-NH 2 ;

[0104] 2) Then load heparin and Cu in the mesoporous channels 2+ ;

[0105] 3) Then modify the surface of nanoparticles with albumin;

[0106] 4) Finally, the nanoparticles were immobilized on the surface of dopamine-modified biomaterials to obtain MSN-NH 2 Coating of @He / Cu.

[0107] In the step 1), the surface modification method of mesoporous silicon nanoparticles is as follows:

[0108] 1.1) Fully mix mesoporous silicon nanoparticles and aminosilane molecular solution;

[0109] 1.2) Shake the reaction for 30 hours, and collect the nanoparticles by centrifugation;

[0110]1.3) Wash with ethanol three times;

[0111] 1.4) MSN-NH was obtained after vacuum drying at 80 degrees Celsius 2 .

[0112] In the step 1.1), ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com