Assembly method for end covers of gas-liquid separator or oil-gas separator

An assembly method and end cap technology, which are applied to resistance welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of low positioning accuracy, inconvenient fixing of brackets, and long welding time, so as to simplify the processing process, and to move left and right. Difficulty, good yielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

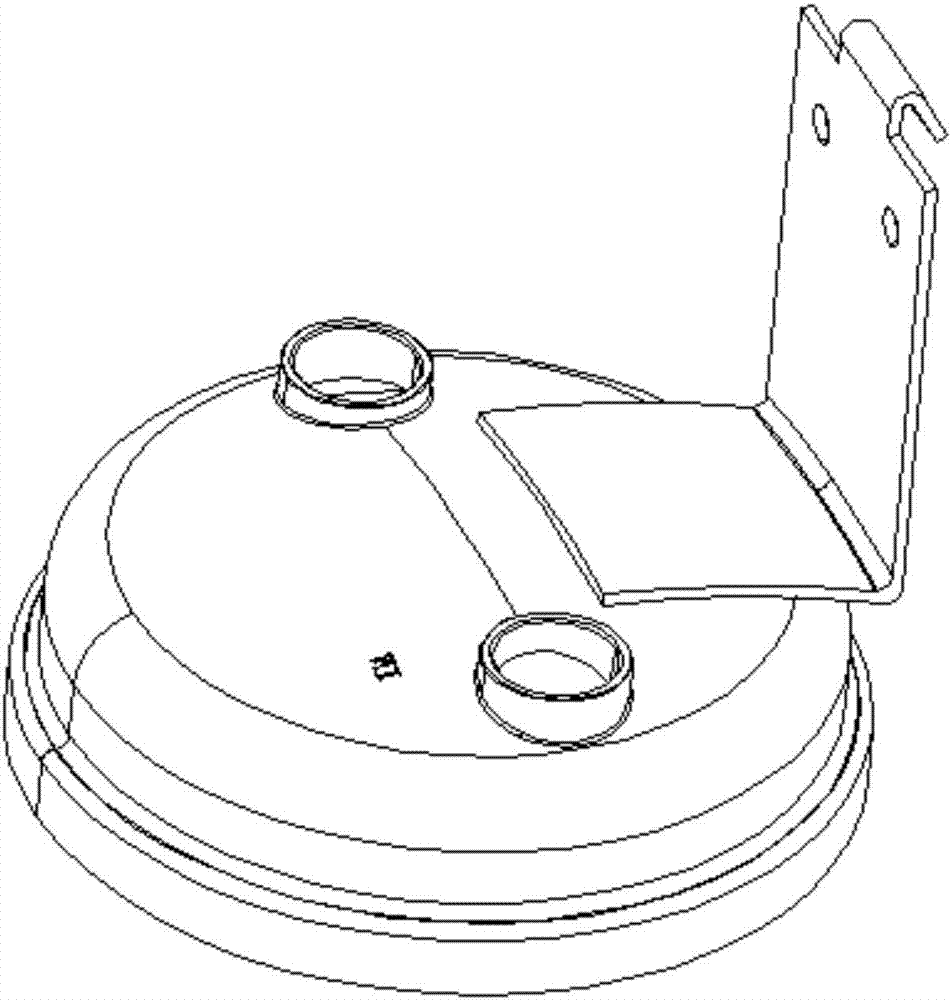

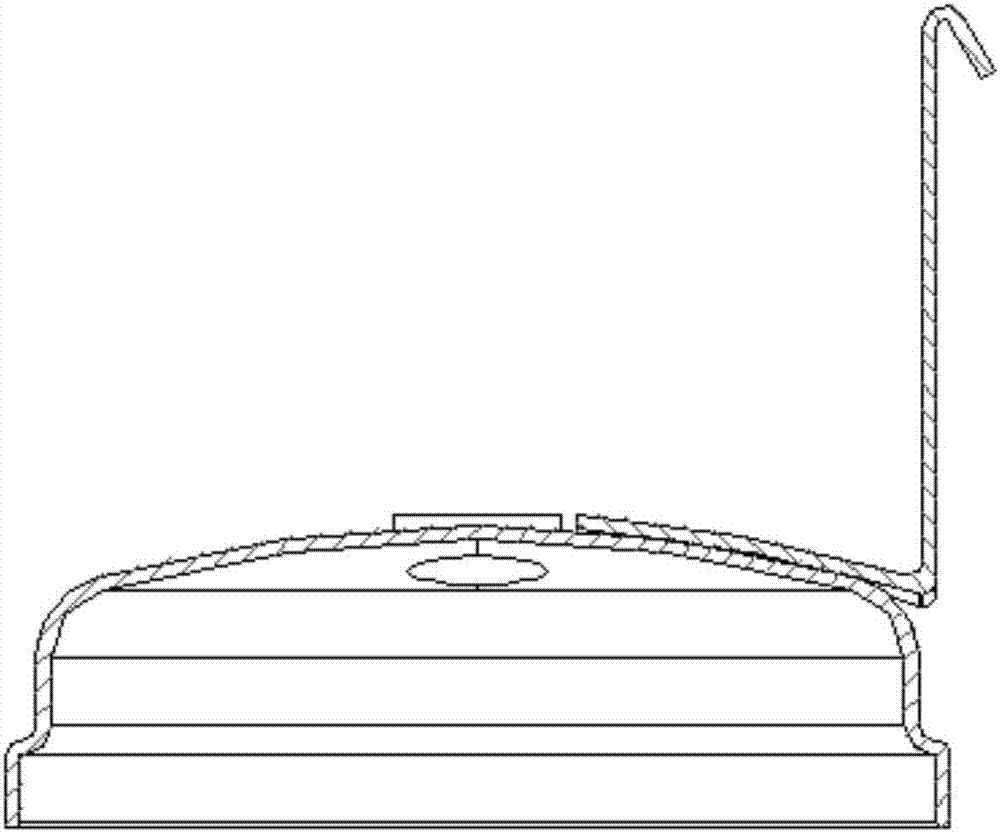

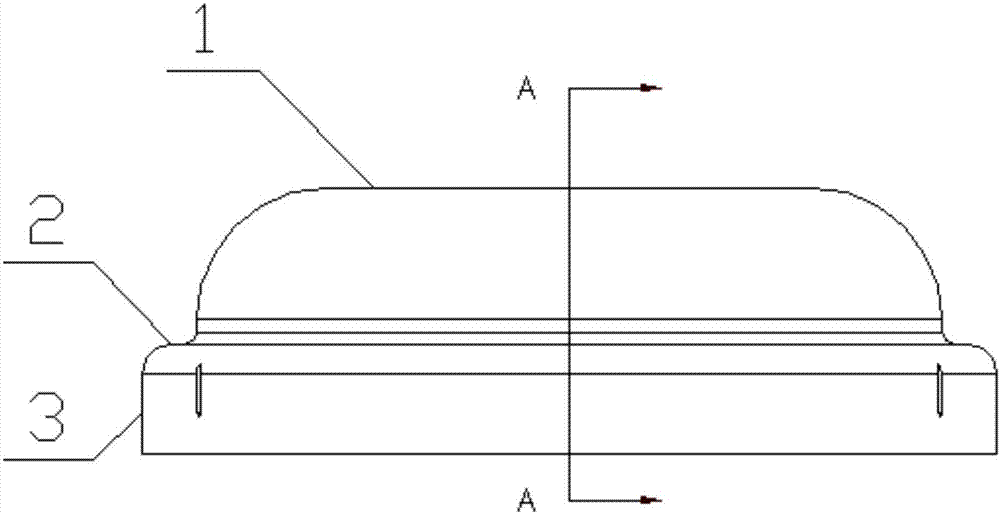

[0043] like Figure 2 to Figure 7 As shown, an end cap for gas separation and oil separation includes a cover body, and the cross section of the cover body sequentially includes a vertical section 3, a horizontal shoulder 2 and at least one plane section 1 from bottom to top. The surface section 3 forms a tubular structure, and the horizontal shoulder 2 and the vertical surface section 3 are perpendicular to each other, and their connection adopts a circular arc transition. The final shape of the device needs to be completed through multiple stamping processes.

[0044] like Figure 4 As shown, the L plane is CO 2 Welding positioning datum plane, M plane is resistance welding positioning datum plane and press fit height guarantee plane, N plane is CO 2 Weld height reference plane.

[0045] In this embodiment, the top of the cover body is a plane segment 1 as a whole, and its shape is specifically circular, and an outwardly protruding arc-shaped curved surface is used betwe...

Embodiment 2

[0052] like Figure 10 to Figure 15 As shown, an end cap for gas separation and oil separation includes a cover body, and the cross section of the cover body sequentially includes a vertical section 3, a horizontal shoulder 2 and at least one plane section 1 from bottom to top. The surface section 3 forms a tubular structure, and the horizontal shoulder 2 and the vertical surface section 3 are perpendicular to each other, and their connection adopts a circular arc transition. The final shape of the device needs to be completed through multiple stamping processes.

[0053] In this embodiment, the top of the cover body as a whole is a plane section 1 and its shape is specifically a quincunx shape. The top of the cover body can be provided with anti-stretch holes-10 as required, such as Figure 4 shown.

[0054] In this embodiment, the inner wall of the vertical surface section 3 is provided with a number of circumferentially arranged inner ribs 5, on the one hand for ensuring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com