Hub enabling mutual refit of drum brake and disc brake

A technology of disc brakes and drum brakes, applied in the field of locomotive hubs, can solve the problems of inability to refit each other, troubles, etc., and achieve the effects of improving convenience, improving versatility, and improving connection firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

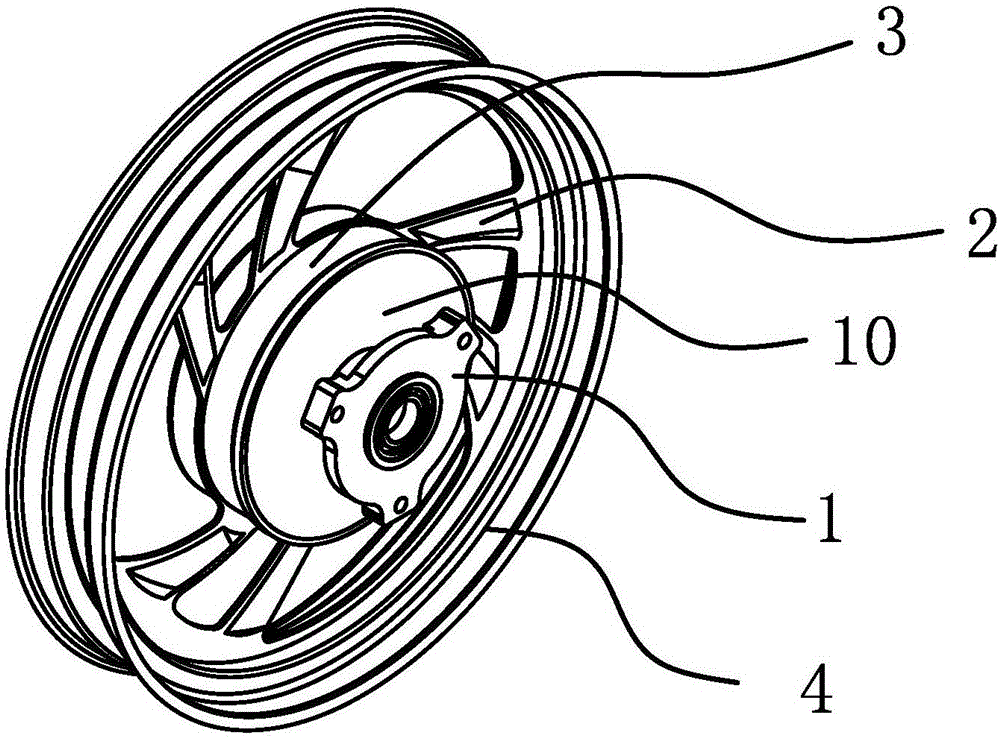

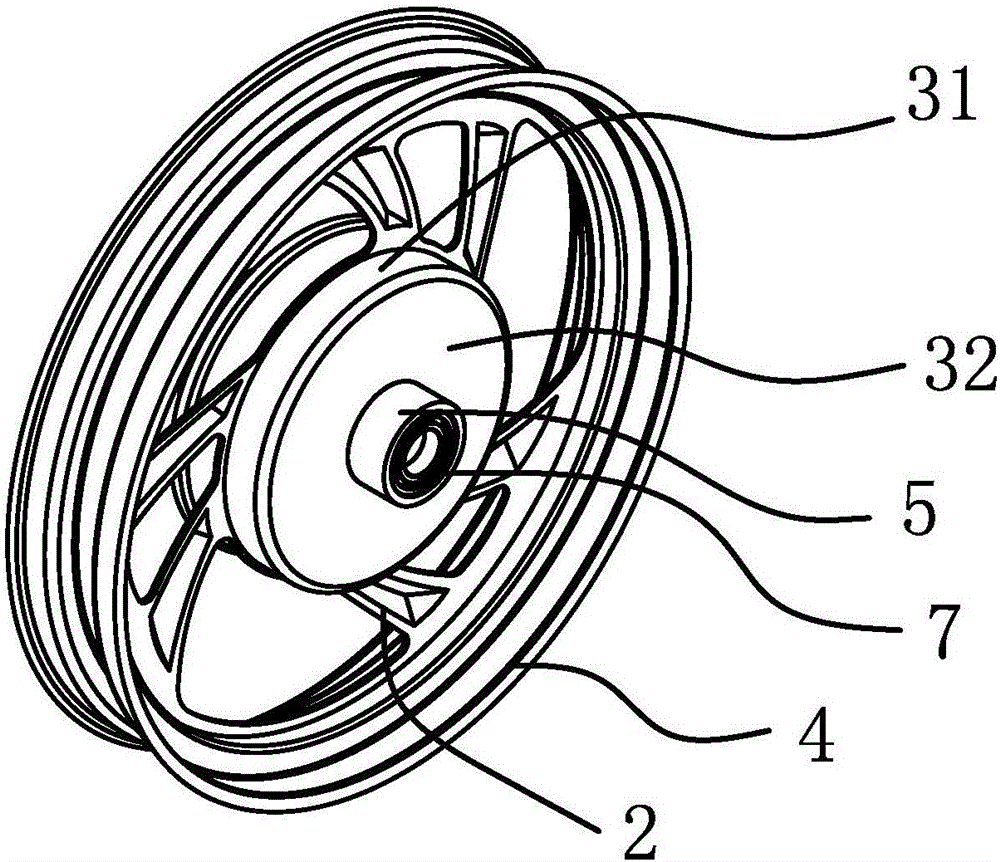

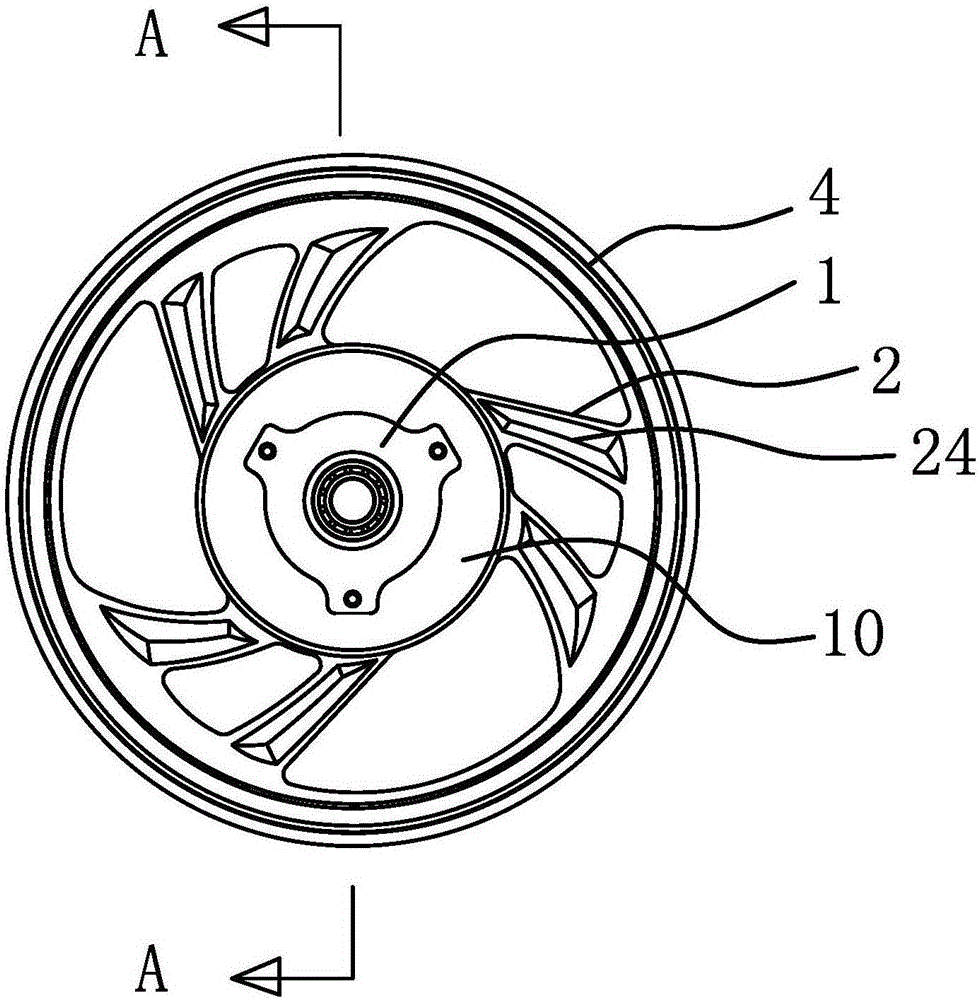

[0032] Such as figure 1 and figure 2As shown, the present embodiment is a wheel hub that can be refitted with a drum brake and a disc brake, which includes a mounting flange 1 for installing a disc brake disc, a spoke 2, a cylindrical brake drum 3 and a rim 4, and the brake The drum 3 is located in the middle of the rim 4 and the two are coaxially arranged. The brake drum 3 is fixedly connected to the rim 4 through the spokes 2. The two ends of the brake drum 3 are respectively an open end 35 and a closed end 36. The brake drum 3 includes The tubular body 31 and the bottom 32 are in an integrated structure, and the bottom 32 closes one end of the body 31 to form a closed end 36 of the brake drum 3 .

[0033] Such as Figure 1-Figure 9 As shown, a bushing 5 passing through the closed end 36 is fixed at the center of the closed end 36. The hub includes a cover plate 10 independent of the brake drum 3, and the cover plate 10 is fixed to the opening of the brake drum 3 by weldi...

Embodiment 2

[0038] The general content of this embodiment is the same as that of the first embodiment, except that, as another solution, the cover plate 10 of this embodiment is detachably fixed to the open end 35 of the brake drum 3 . The detachable fixing at the open end 35 of the cover plate 10 and the brake drum 3 is connected and fixed by a threaded member or fixed by a buckle connection. The threaded connection generally includes screws or bolts, which are relatively easy to install and disassemble. The advantage of detachable fixing is that it can be disassembled conveniently, which improves the convenience of modification.

Embodiment 3

[0040] The general content of this embodiment is the same as that of the first embodiment, except that, as another solution, the cover plate 10 of this embodiment is fixed to the open end 35 of the brake drum 3 by riveting. The rivet connection requires a certain degree of violent destruction, relatively speaking, the damage is not large, the cost is also low, and the disassembly is more convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com