Disk spring set for shock insulation support

A technology of disc springs and shock-isolation bearings, which is applied in the direction of shock resistance, building components, building types, etc., can solve the problems of disc springs being unable to deform, disc springs with poor shock-isolation effects, and loss of shock-isolation effects. Achieve the effect of simple and effective stiffness adjustable and good welding fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

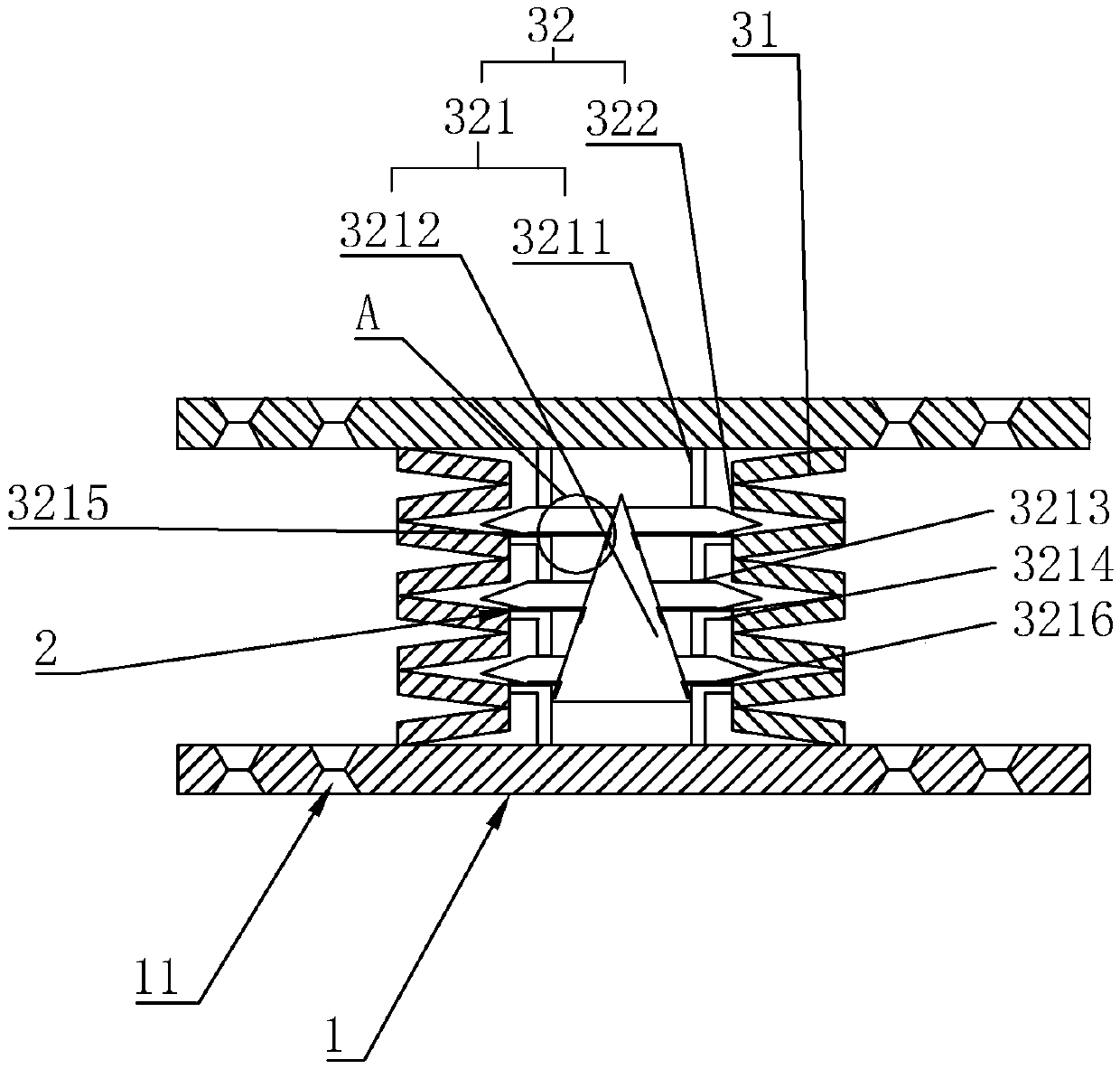

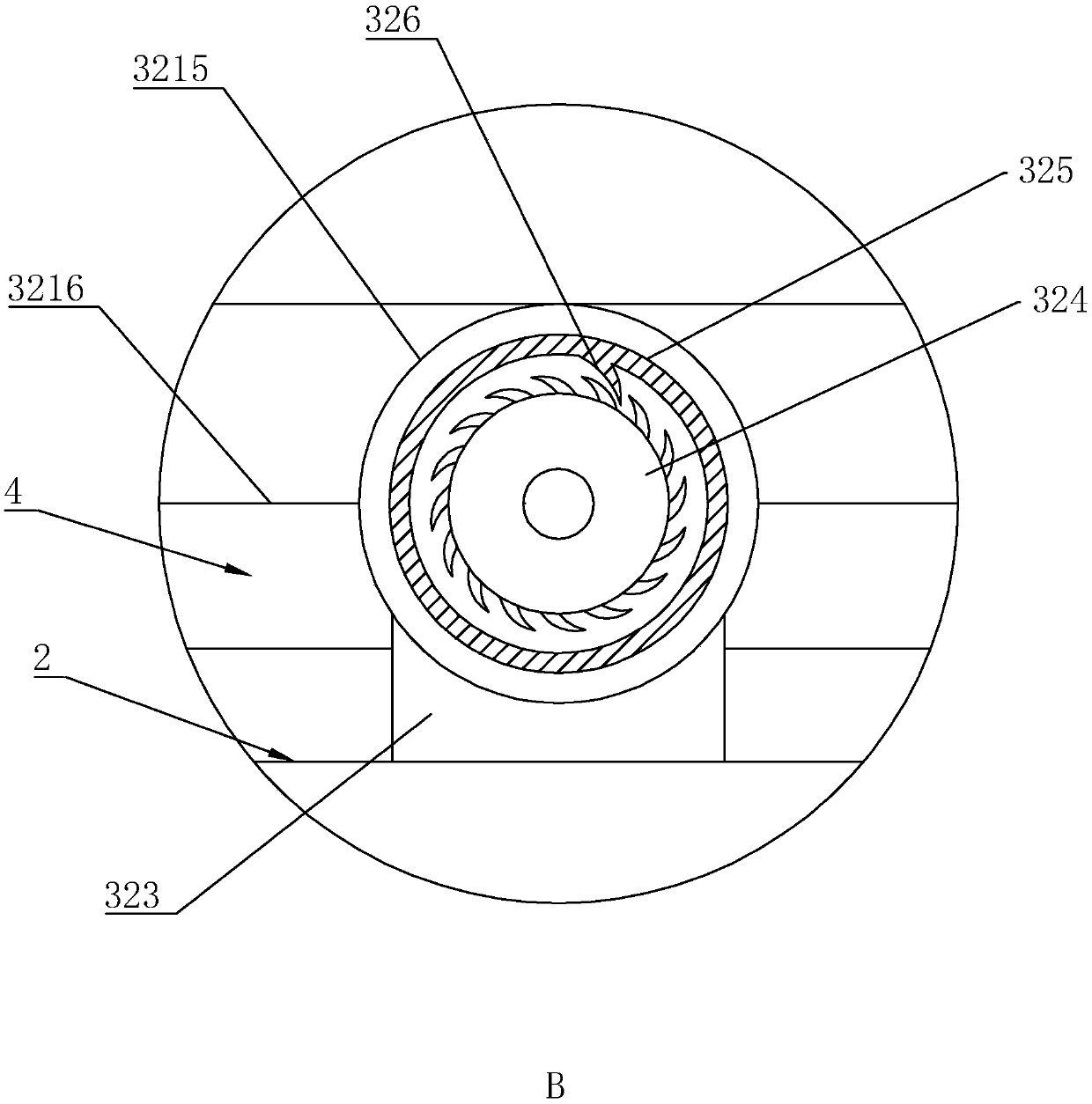

[0017]As an improved specific implementation, the vibration detection assembly 321 includes a column housing 3211 and a detection column 3212. The column housing 3211 is hollow and expandable, and its two ends are respectively fixed to the upper connecting plate 1 and the lower connecting plate 2. Connected, coaxially arranged in the disc spring 31, the detection column 3212 is slidably arranged in the column housing 3211, and the position of the side wall of the column housing 3211 relative to the interlayer of the disc spring 31 corresponds one by one There is a drive hole 3213 for the elastic block 322 to pass through, and the elastic block 322 is passed through the drive hole 3213, and is linked with the side wall of the detection column 3212, when the detection column 3212 slides up and down in the column housing 3211 , the detection column 3212 pushes the elastic block 322 to slide into the interlayer of the disc spring 31, or slides out from the interlayer. When the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com