Middle-convex doubling-free spring and mixed-density media double-cylinder double-mass vibration mill

A technology of mixing density and coil spring, which is applied in the field of grinding equipment prepared by vibration of ultra-fine powder, can solve the problems of low efficiency and high noise, reduce vibration intensity and noise, prevent resonance and flutter, and prevent horizontal movement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

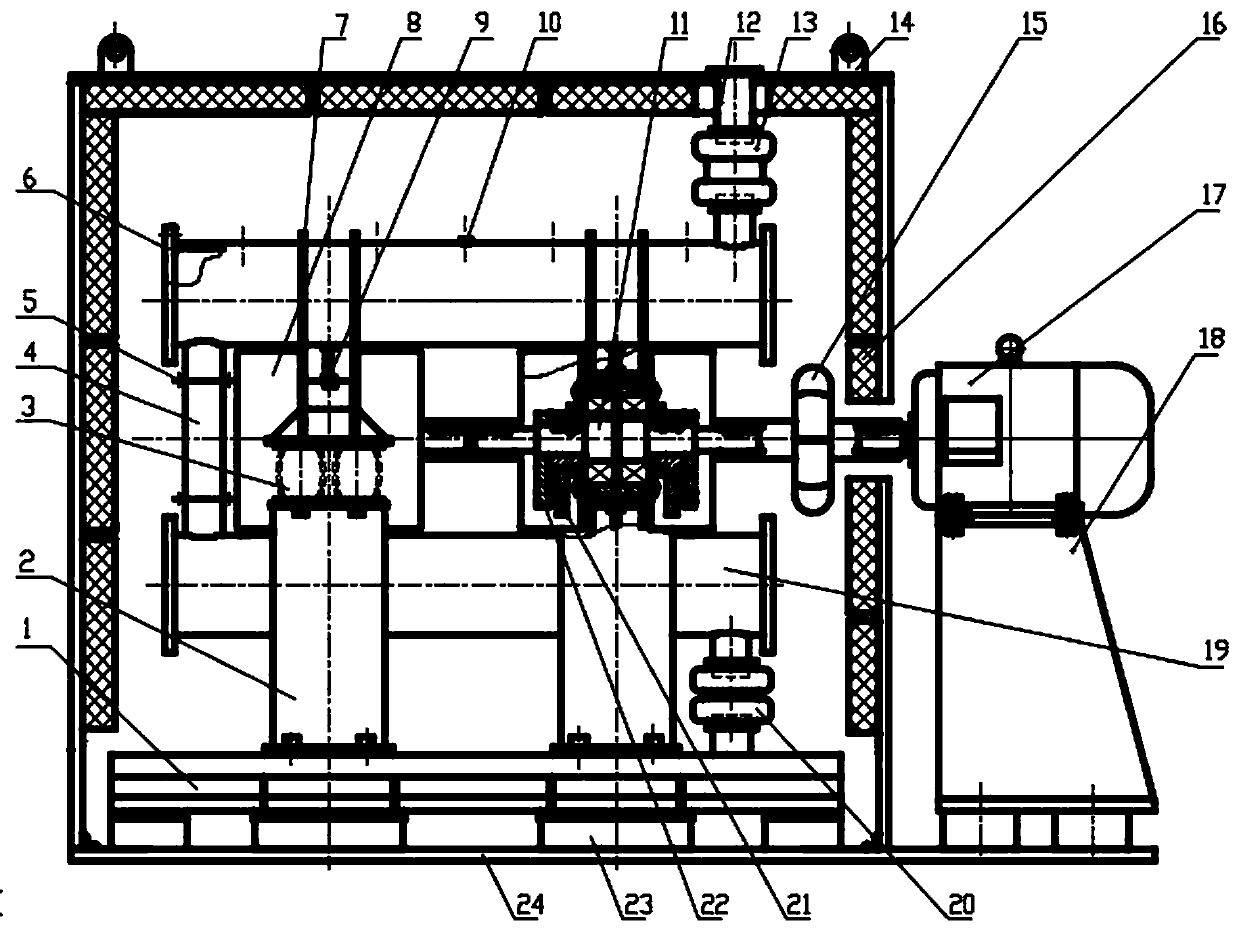

[0036] Such as figure 1 As shown, the material is continuously added from the feed port 12, and is screened through the upper cylinder 6, the lower cylinder 19 and the screens of each cylinder during the vibration process, and the finished product is continuously discharged from the discharge port 20. During the working process, the grinding media of the upper and lower cylinders The filling coefficient is 0.65, and the grinding medium is wear-resistant steel ball and tungsten steel ball. The diameter of the grinding medium depends on the particle size of the material to be ground, generally 3-30mm, and its grinding efficiency is high; the vibration frequency of the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com