Method for using fish solution to produce food grade flavor agent

A technology of umami agent and fish dissolving pulp is applied in the directions of food ingredients as taste improver, function of food ingredients, food ingredients, etc., which can solve the problems of high preparation cost, cumbersome preparation method and the like, and achieves simple and reproducible preparation method. Good performance and small molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A method for producing a food-grade flavoring agent utilizing fish lysate, comprising the following steps:

[0018] 1) Pretreatment: Add ethanol 3 to 6 times the volume of the fish soluble slurry to the fish soluble slurry, and centrifuge to collect the precipitate. Ethanol can destroy the hydration layer on the surface of the protein, causing its solubility in water to drop rapidly, and it is separated in the form of precipitation, and the protein activity will not be destroyed;

[0019] 2) Pepsin enzymatic hydrolysis: Add pepsin to the precipitate, the amount of pepsin added is 0.4~0.7%, the enzymolysis temperature is 35~40°C, the pH is 1.7~2.7, and the enzymolysis time is 20~30min. Microwave-assisted enzymatic hydrolysis, the microwave power is 100~120W, and the frequency is 20~30kHZ. Microwave-assisted enzymatic hydrolysis can greatly shorten the time of protease enzymatic hydrolysis, reduce time and labor costs, and reduce production costs. After enzymatic hydrol...

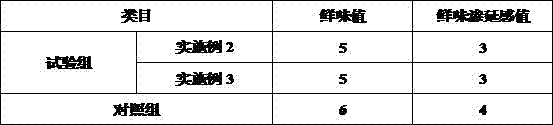

Embodiment 2

[0024] A method for producing a food-grade flavoring agent utilizing fish lysate, comprising the following steps:

[0025] 1) Pretreatment: Add ethanol 5 times the volume of the fish soluble slurry to the fish soluble slurry, and centrifuge to collect the precipitate. Ethanol can destroy the hydration layer on the surface of the protein, causing its solubility in water to drop rapidly, and it is separated in the form of precipitation, and the protein activity will not be destroyed;

[0026] 2) Pepsin enzymatic hydrolysis: Add pepsin to the precipitate, the amount of pepsin added is 0.6%, the enzymolysis temperature is 37°C, the pH is 2.0, and the enzymolysis time is 24min. Microwave-assisted enzymolysis, the microwave power is 120W, and the frequency is 25kHZ. Microwave-assisted enzymatic hydrolysis can greatly shorten the time of protease enzymatic hydrolysis, reduce time and labor costs, and reduce production costs. After the enzymatic hydrolysis, the enzyme was inactivate...

Embodiment 3

[0031] A method for producing a food-grade flavoring agent utilizing fish lysate, comprising the following steps:

[0032] 1) Pretreatment: Add ethanol 5 times the volume of the fish soluble slurry to the fish soluble slurry, and centrifuge to collect the precipitate. Ethanol can destroy the hydration layer on the surface of the protein, causing its solubility in water to drop rapidly, and it is separated in the form of precipitation, and the protein activity will not be destroyed;

[0033] 2) Pepsin enzymatic hydrolysis: Add pepsin to the precipitate, the amount of pepsin added is 0.7%, the enzymolysis temperature is 37°C, the pH is 2.0, and the enzymolysis time is 25min. Microwave-assisted enzymolysis, the microwave power is 120W, and the frequency is 25kHZ. Microwave-assisted enzymatic hydrolysis can greatly shorten the time of protease enzymatic hydrolysis, reduce time and labor costs, and reduce production costs. After the enzymatic hydrolysis, the enzyme was inactivate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com