Glass insulator hermetically sealed packaging structure and welding method for microwave devices

A technology of glass insulators and hermetic packaging, which is applied to waveguide devices, electrical components, circuits, etc., can solve the problems of lower product quality, failure to prevent solder spreading, high equipment and labor costs, etc., to improve efficiency, reduce process control and The difficulty of production operation and the effect of reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

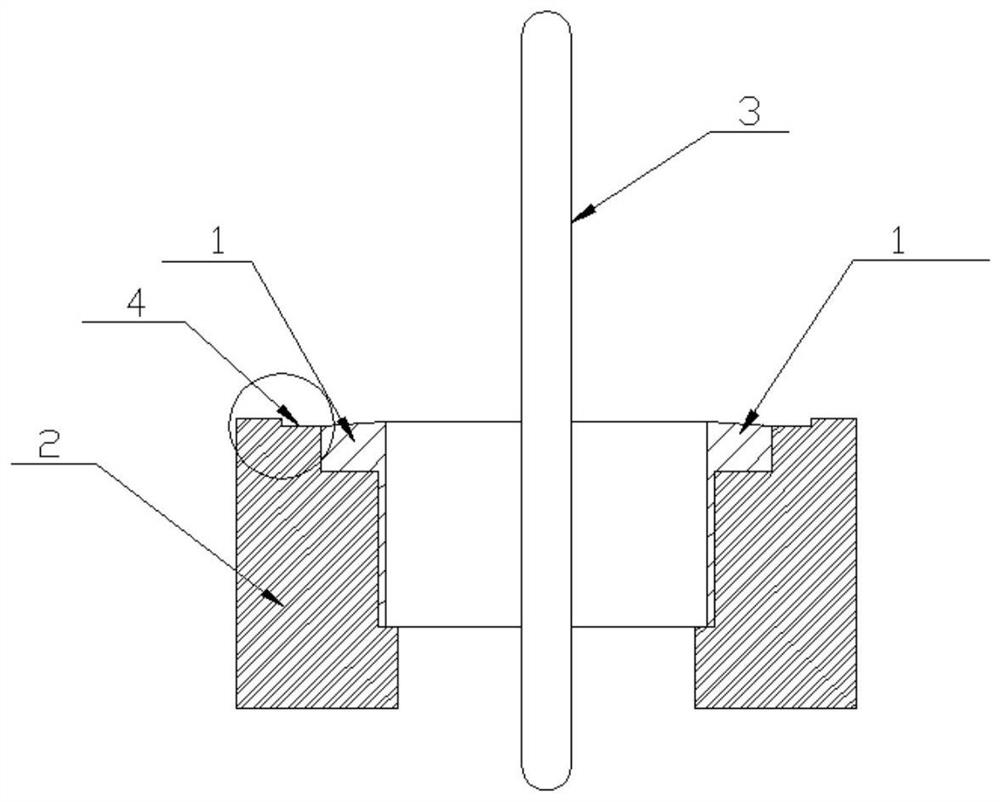

[0019] like Figure 1-2 As shown in the figure, a glass insulator hermetic packaging structure for a microwave device includes a gold-plated cavity wall 2 and a glass insulator 3. The glass insulator 3 is welded between the gold-plated cavity walls 2 and is located in the center, and the upper part of the gold-plated cavity wall 2 is adjacent to the upper part. A solder tank 1 is provided at the top, and a solder resist structure 4 is provided on the top of the solder tank 1 .

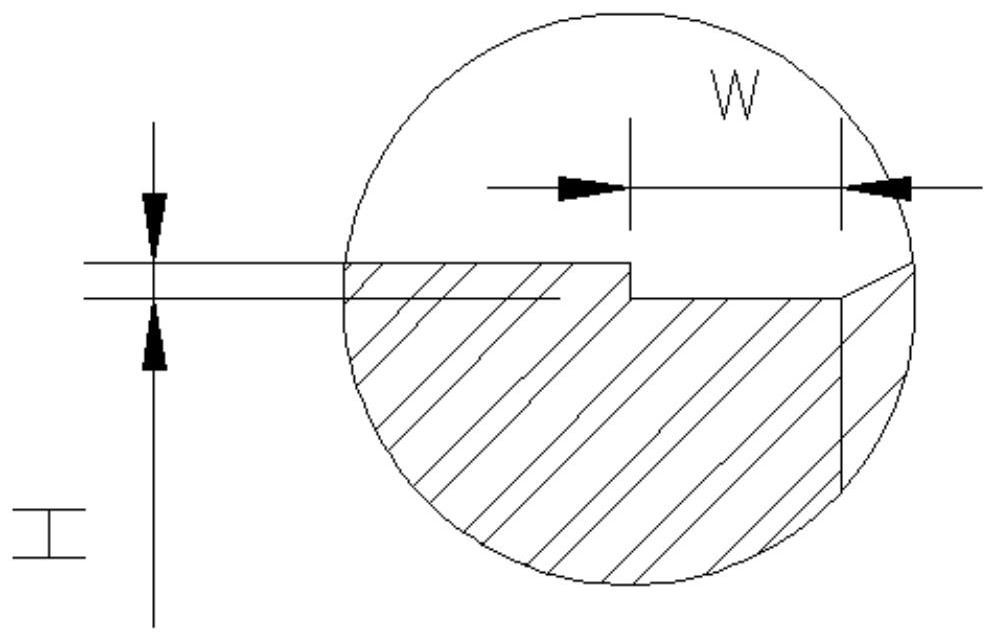

[0020] The solder resist structure 4 is of an L-step type, and the top is at the same level as the top of the gold-plated cavity wall 2 .

[0021] The height H of the solder resist structure 4 in the vertical direction is 0.05 mm, and the width W in the horizontal direction is 0.3 mm.

[0022] Both the vertical surface and the horizontal surface of the solder resist structure 4 are non-gold-plated surfaces, and the non-gold-plated surface is preferably an aluminum alloy surface.

Embodiment 2

[0024] A tin-free leakage welding method for a glass insulator airtight packaging structure of a microwave device, the method welds the glass insulator and the gold-plated cavity, and the method adopts the soldering resistance structure 4 provided on the top of the soldering tank 1 in Example 1 to prevent tin The base solder spreads toward the cavity walls.

[0025] In the present invention, due to the arrangement of the solder resist structure 4 on the aluminum alloy surface, since the aluminum alloy and the tin-based solder cannot form a wetted surface and cannot form welding, the solder resist structure 4 prevents the tin-based solder from spreading to the cavity wall, which greatly reduces the The difficulty of process control and production operation is improved, the sealing performance of the glass insulator hermetic packaging structure of the microwave device after welding is improved, the appearance after welding is beautiful, and there is no tin leakage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com