Steel ladle buggy transverse movement device and application method thereof

A technology of ladle trolley and traverse device, which is applied to casting melt containers, metal processing equipment, casting equipment, etc., can solve the problem that the running routes cannot interfere with each other, and shorten the waiting time, auxiliary operation time, and restrictions. The effect of the condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

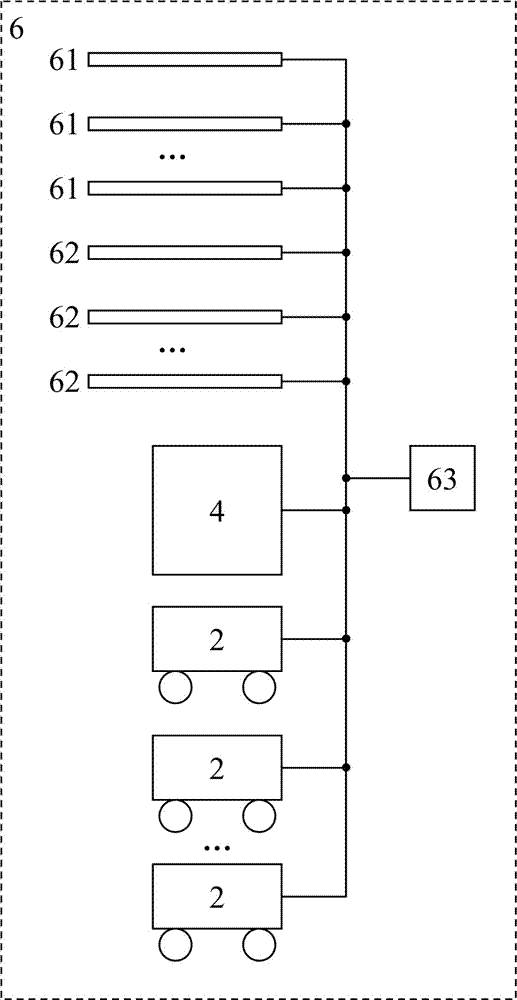

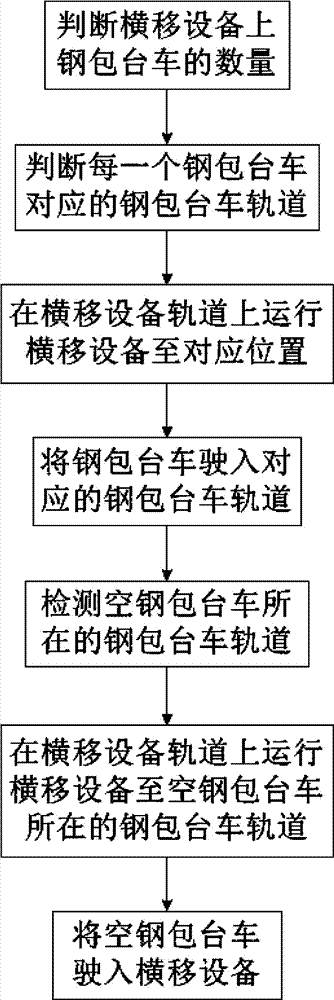

[0044] A ladle trolley traversing device, comprising a trolley track 1, a ladle trolley 2, a traversing track 3, a traversing platform 4, a connecting track 5 and a control unit 6, such as figure 1 and figure 2 As shown, the specific structure is:

[0045] There is at least one trolley track 1, each trolley track 1 is parallel to each other, and each trolley track 1 is provided with at most one ladle trolley 2;

[0046]The middle part of the trolley track 2 is disconnected, and the traversing track 3 is laid at the disconnection, the traversing track 3 and the trolley track 1 are obliquely intersected, and the traversing platform 4 is arranged on the traversing track 3 and along the traversing track 3 move;

[0047] The connecting track 5 is laid on the traversing platform 4, there are at least two connecting tracks 5, each connecting track 5 is parallel to each other, and the connecting track 5 and the trolley track 1 are parallel to each other, the gauge of the connecting...

Embodiment 2

[0062] A ladle trolley traversing device, comprising a trolley track 1, a ladle trolley 2, a traversing track 3, a traversing platform 4, a connecting track 5 and a control unit 6, such as Figure 4 As shown, the traversing platform 4 is arranged between the molten steel receiving span and the refining span. The molten steel receiving span is provided with three trolley tracks 1, and two ladle trolleys 2 are arranged. The traversing platform 4 can connect the two ladle trolleys 2 to the The track 5 is alternately aligned with the trolley track 1 of the secondary refining treatment position, and the ladle trolley 2 for secondary refining can drive from the traversing platform 4 to the secondary refining treatment position, and travel to the secondary refining treatment position through the traversing platform 4 after processing The molten steel accepts the trolley track 1 across.

[0063] When a ladle trolley 2 was carrying a ladle of molten steel and was processing it, the lad...

Embodiment 3

[0067] A ladle trolley traversing device, comprising a trolley track 1, a ladle trolley 2, a traversing track 3, a traversing platform 4, a connecting track 5 and a control unit 6, such as Figure 5 As shown, the traversing platform 4 is arranged in the molten steel receiving span, and two ladle trolleys 2 are arranged. The traversing platform 4 can make the two ladle trolleys 2 alternately align with the trolley track 1 of the secondary refining treatment position. The secondary refining ladle trolley 2 can drive to the secondary refining treatment position from the traversing platform 4, and can drive back on the traversing platform 4 after the treatment is finished.

[0068] When a ladle trolley 2 was carrying a ladle of molten steel and was processing it, the ladle to be processed smelted by the converter could be hoisted to another ladle trolley in the two ladle trolleys 2 by the crane; After the secondary refining process is completed, the processed ladle is transported ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com