Heat pump type concentration control method of vegetable protein extraction and sterilization technology feed liquid

A control method and plant protein technology, applied in the field of heat pump concentration control, can solve the problems of low production capacity and low concentration of spray drying, achieve general industrial application value and social and economic benefits, increase production, reduce energy consumption and water resource consumption volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

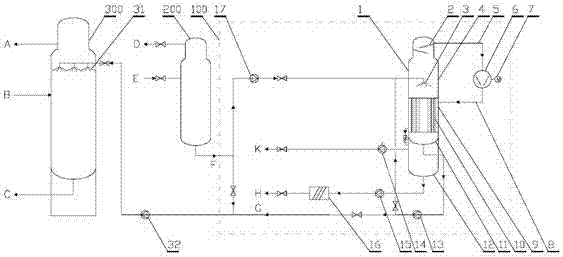

[0013] figure 1 It is a schematic diagram of the system of the present invention.

[0014] Specific embodiments of the present invention are as follows: a heat pump concentration control method for vegetable protein extraction and sterilization process feed liquid, using heat pump low-pressure distillation technology to increase the concentration of the flash tank effluent feed liquid, and returning all the separated water to For the extraction process, it is characterized in that the concentration control method adds a feed-liquid concentration process system 100 based on heat pump low-pressure distillation technology, and the feed-liquid concentration process system 100 includes heat pump low-pressure distillation and material separation modules, condensed water The processing and recycling module and the concentrated material liquid post-processing and recovery module are composed of three parts and related connecting pipelines and pipe fittings. The heat pump low-pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com