Kieselguhr board based on two to three-level kieselguhr and preparation method thereof

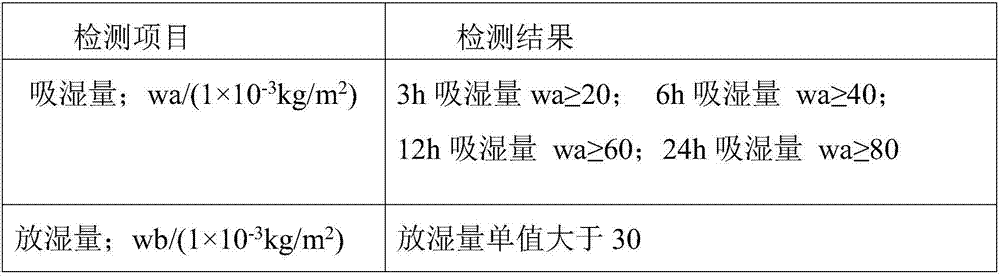

A technology of diatomite and diatom, applied in the field of building materials, can solve the problem of unable to replace decorative boards, etc., and achieve the effects of excellent humidity control, low density and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

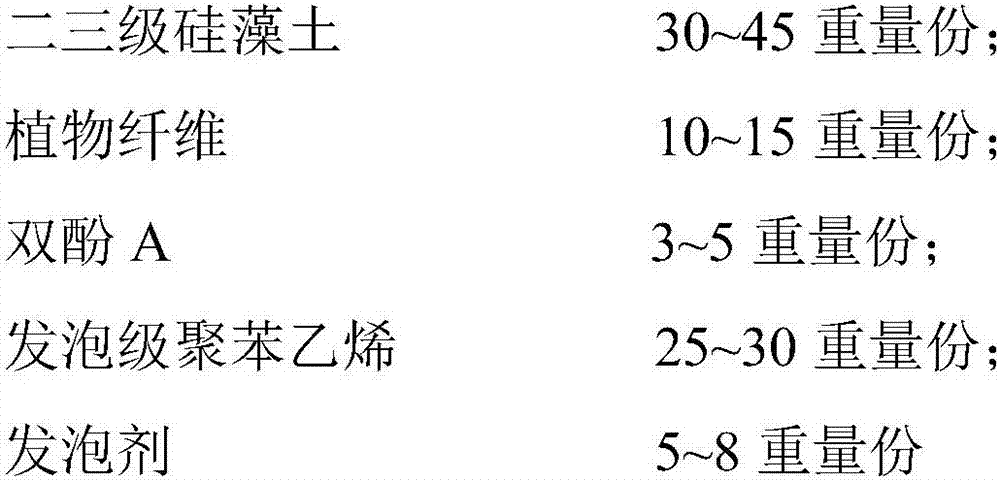

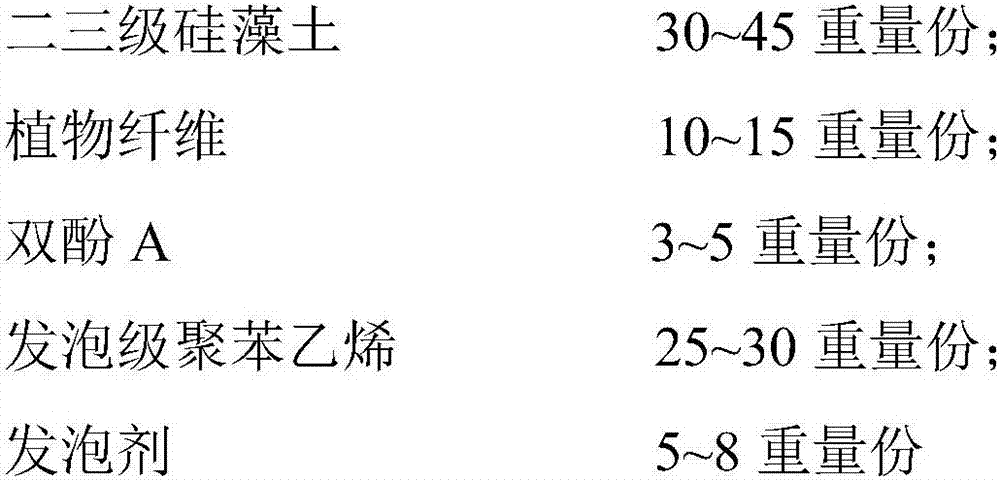

[0041] The preparation method of the above-mentioned diatomite board based on two or three grades of diatomite comprises the following steps:

[0042] Step 1, batching according to the proportioning ratio, stirring and mixing evenly to obtain the mixed material;

[0043] Among them, the stirring speed is generally 1200-1500r / min, and the time is 10-20min;

[0044]Step 2. After diluting the mixed material with water, stir evenly, pave and shape, remove moisture under negative pressure, and after heat balance, stand and solidify to obtain a slab;

[0045] Among them, the stirring speed is generally 1100 ~ 1300r / min, the time is 5 ~ 10min, the removal of moisture is generally under vacuum -0.05 ~ -0.1MPa for 10 ~ 60min, and the water content reaches 6 ~ 10%; the heat balance is preferably maintained at room temperature 5-6 days; static curing time is generally more than 24h;

[0046] Step 3, forming the slab by hot pressing to obtain a rough slab;

[0047] The pressure of hot ...

Embodiment 1

[0052] The diatomite board based on two or three grades of diatomite consists of two or three grades of diatomite (fineness 200 mesh, whiteness 80) of 40 parts by weight, pulp of 12 parts by weight, bisphenol A of 4 parts by weight, 25 parts by weight Parts by weight of expanded polystyrene, 7 parts by weight of sodium bicarbonate, 0.3 parts by weight of diatomaceous earth white carbon black loaded nano-titanium dioxide composite photocatalytic material (whiteness is 85, the loading of nano-titanium dioxide is 40%) composition .

[0053] The preparation method of the diatomite board based on the above-mentioned secondary and tertiary diatomite:

[0054] Step 1, batching according to the above proportioning ratio, stirring and mixing evenly to obtain the mixed material;

[0055] Wherein, the stirring speed is 1200r / min, and the time is 10min;

[0056] Step 2. After diluting the mixed material with water, stir evenly, pave and shape, remove moisture under negative pressure, an...

Embodiment 2

[0077] The diatomite board based on two or three grades of diatomite consists of two or three grades of diatomite (fineness 200 mesh, whiteness 80) of 30 parts by weight, paper pulp of 10 parts by weight, bisphenol A of 3 parts by weight, 20 Parts by weight of expanded polystyrene, 5 to 8 parts by weight of azodicarbonamide, 0.1 parts by weight of diatomaceous earth white carbon black loaded nano-titanium dioxide composite photocatalytic material (the whiteness is 80, and the loading capacity of nano-titanium dioxide is 40%, grain size ≤ 15nm) composition.

[0078] The preparation method of the diatomite board based on the above-mentioned secondary and tertiary diatomite:

[0079] Step 1, batching according to the above proportioning ratio, stirring and mixing evenly to obtain the mixed material;

[0080] Wherein, the stirring speed is 1500r / min, and the time is 10min;

[0081] Step 2. After diluting the mixed material with water, stir evenly, pave and shape, remove moisture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com