Preparation method and application of Cu-SSZ-13 catalyst

A catalyst, cu-ssz-13 technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of raw sewage, unfavorable large-scale promotion and application of catalysts, and low yield, etc. No waste water pollution, excellent N2 generation selectivity, high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

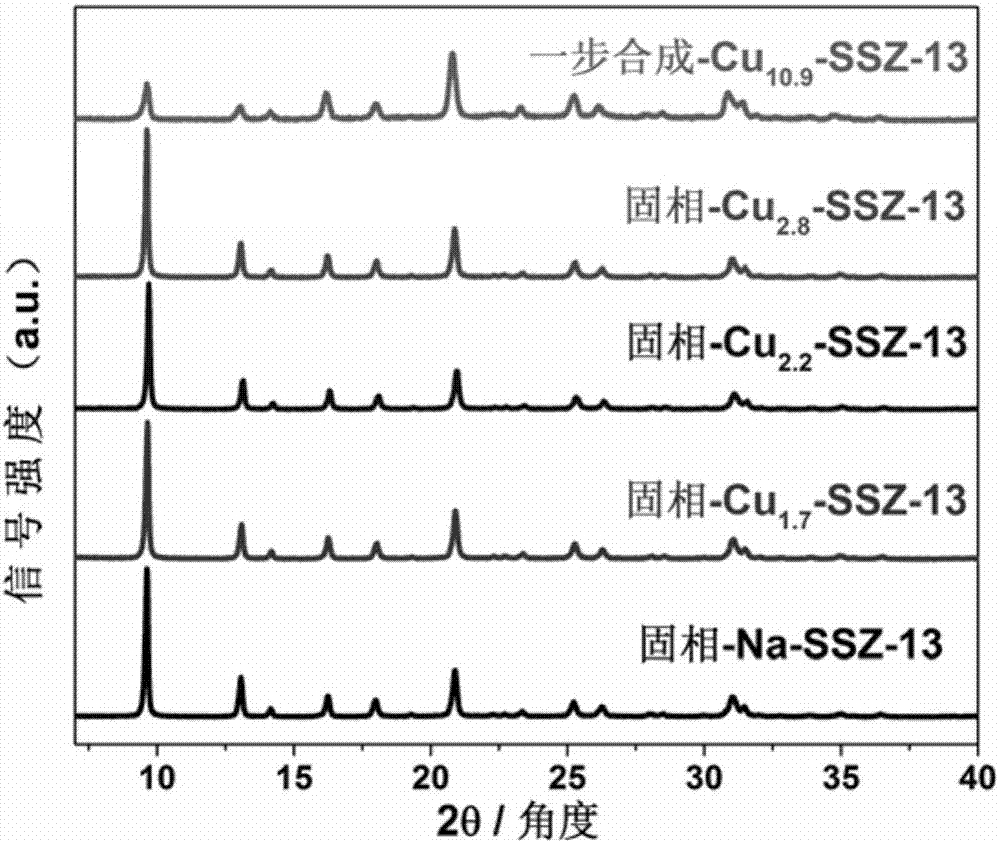

Embodiment 1

[0045] The preparation process of the Na-SSZ-13 molecular sieve carrier of this embodiment is as follows: 1.412g of sodium silicate, 1.368g of silicon dioxide, 0.65g of aluminum sulfate, 0.8g of N,N,-dimethyl-N -Ethylcyclohexylammonium bromide template and 0.05g of seed crystal H-SSZ-13 were put into a mortar for grinding, and after being evenly ground, they were placed in a reaction kettle for crystallization at 180°C for 5 days, and then suction filtered and washed. Put the filter cake in an oven at 100°C overnight, and finally bake it in air at 600°C for 6 hours to obtain a Na-SSZ-13 molecular sieve carrier.

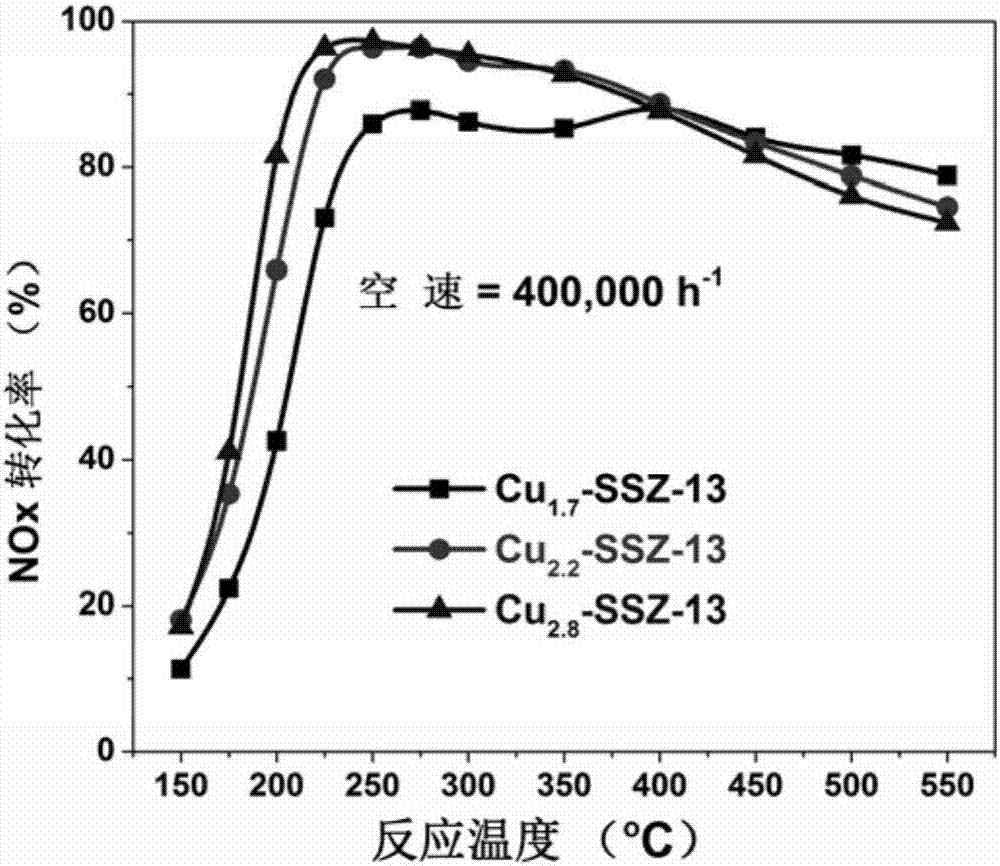

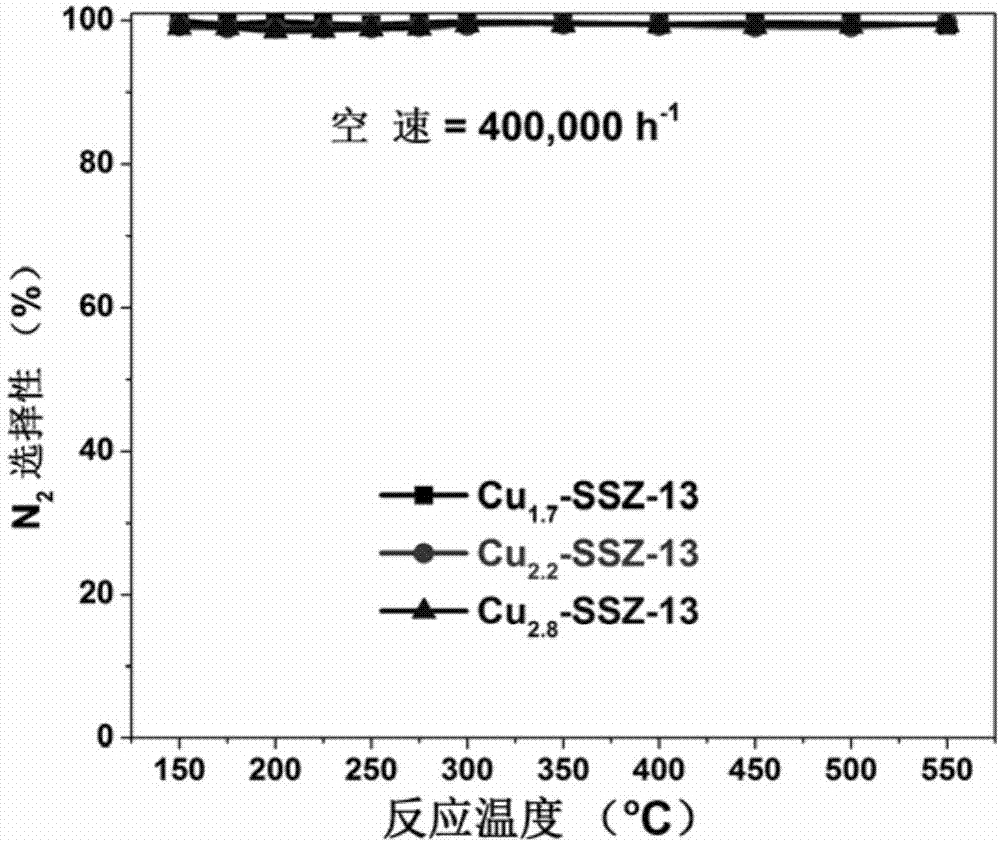

Embodiment 2

[0047] The preparation process of the Cu-SSZ-13 catalyst of the present embodiment is as follows: the Na-SSZ-13 molecular sieve carrier prepared in Example 1 and 1mol / L NH 4 NO 3 The solution was stirred at 80°C for 5h, then filtered, washed and dried again to obtain NH 4 - SSZ-13 powdered molecular sieve. NH will be produced 4 -SSZ-13 molecular sieve and 0.1mol / L Cu(NO 3 ) 2 The solution was stirred at room temperature for 24 hours, and then filtered, washed, dried and calcined again to obtain Cu-SSZ-13 powder catalyst. The prepared catalyst is pressed into tablets, ground, sieved, and 40-60 meshes are taken for later use. Catalysts with different Cu loadings passed Cu(NO 3 ) 2 The number of times of ion exchange of the solution is adjusted. In this embodiment, Cu with a mass percentage of 1.7% Cu loading is obtained through 1 ion exchange. 1.7 - SSZ-13 catalyst.

Embodiment 3

[0049] The preparation process of the Cu-SSZ-13 catalyst of the present embodiment is as follows: the Na-SSZ-13 molecular sieve carrier prepared in Example 1 and 1mol / L NH 4 NO 3 The solution was stirred at 80°C for 5h, then filtered, washed and dried again to obtain NH 4 - SSZ-13 powdered molecular sieve. The prepared NH4-SSZ-13 molecular sieve was mixed with 0.1mol / L Cu(NO 3 ) 2 The solution was stirred at room temperature for 24 hours, and then filtered, washed, dried and calcined again to obtain Cu-SSZ-13 powder catalyst. The prepared catalyst is pressed into tablets, ground, sieved, and 40-60 meshes are taken for later use. Catalysts with different Cu loadings passed Cu(NO 3 ) 2 The number of times of ion exchange of the solution is adjusted, and the present embodiment obtains Cu with a mass percentage of 2.2% Cu loading through 2 ion exchanges. 2.2 - SSZ-13 catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com