TPO thermoplastic elastomer material and preparation method thereof

A thermoplastic elastomer and granule technology, which is applied in the field of processing aids for plastic products, can solve the problems of poor waterproof performance, low toughness, and low rigidity, and achieve strong waterproof performance, excellent toughness, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] A kind of TPO thermoplastic elastomer material and preparation method thereof, comprises the steps:

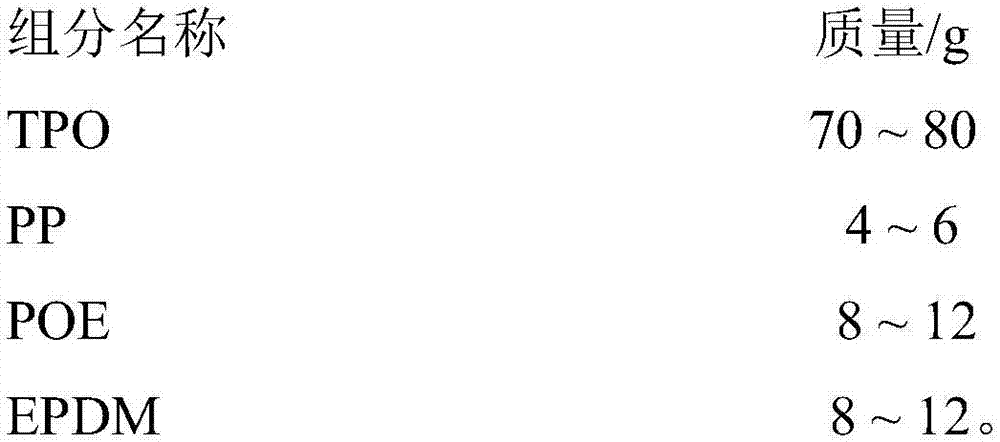

[0019] 1) Physical treatment: In terms of mass fraction, mix 70g-80g of TPO, 4g-6g of PP, 8g-12g of POE, and 8g-12g of EPDM, add it to an ultrasonic cleaner, and clean it ultrasonically for more than 2 hours at room temperature , placed in an oven after filtering, and dried at 70-80°C until the moisture on the surface of each component material disappears, and the dry mixture is obtained;

[0020] 2) Melt blending: Add the dry mixture and a certain amount of fusion agent into the 75L internal mixer, at a temperature of 180-190°C, the rotor speed is 35-70r / min, and the motor speed is controlled at 490-980r / min. Blending and banburying under the same conditions for 20 minutes to obtain the crude compound;

[0021] 3) Granulation molding: the crude compound is transported to the granulator through the conveyor, and at 185°C, the crude compound is cut into particles of dif...

Embodiment 1

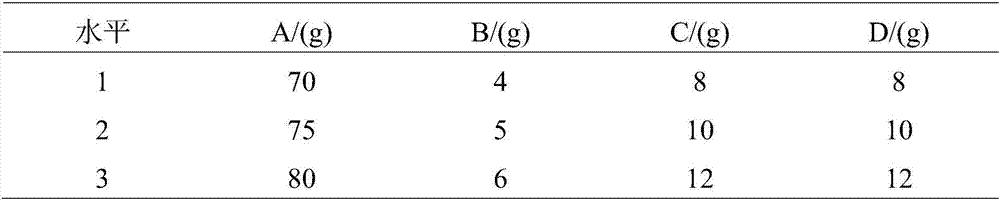

[0026] Mix 70g of TPO, 4g of PP, 8g of POE, and 8g of EPDM, put them into an ultrasonic cleaner, and clean them ultrasonically for more than 2 hours at room temperature. After filtering, place them in an oven and dry them at 100-120°C After 4 hours, the dry mixture was obtained, and the dry mixture and a certain amount of fusion agent were added to a 75L internal mixer, and the temperature was 185°C, the rotor speed was 55r / min, and the motor speed was controlled at 750r / min. Refining for 20 minutes, the crude compound is obtained. The crude compound is transported to the granulator through the conveyor, and the crude compound is cut into particles of different particle sizes at 185 ° C. Finally, the particles are put into molds of different shapes. Prepare PP / POE / EPDM type TPO thermoplastic elastomer material.

Embodiment 2

[0028] Mix 70g of TPO, 5g of PP, 10g of POE, and 10g of EPDM, put them into an ultrasonic cleaner, and clean them ultrasonically for more than 2 hours at room temperature. After filtering, place them in an oven and dry them at 100-120°C. After 4 hours, the dry mixture was obtained, and the dry mixture and a certain amount of fusion agent were added to a 75L internal mixer, and the temperature was 185°C, the rotor speed was 55r / min, and the motor speed was controlled at 750r / min. Refining for 20 minutes, the crude compound is obtained. The crude compound is transported to the granulator through the conveyor, and the crude compound is cut into particles of different particle sizes at 185 ° C. Finally, the particles are put into molds of different shapes. Prepare PP / POE / EPDM type TPO thermoplastic elastomer material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com