Low-temperature ultra-fine desulfurizing agent and preparation method thereof

A technology of fine desulfurization and desulfurization agent, applied in the field of low temperature ultrafine desulfurization agent and its preparation, and ultrafine desulfurization agent, can solve problems such as easy poisoning and deactivation, and achieve the effects of improving impregnation rate, simple production process and increasing load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

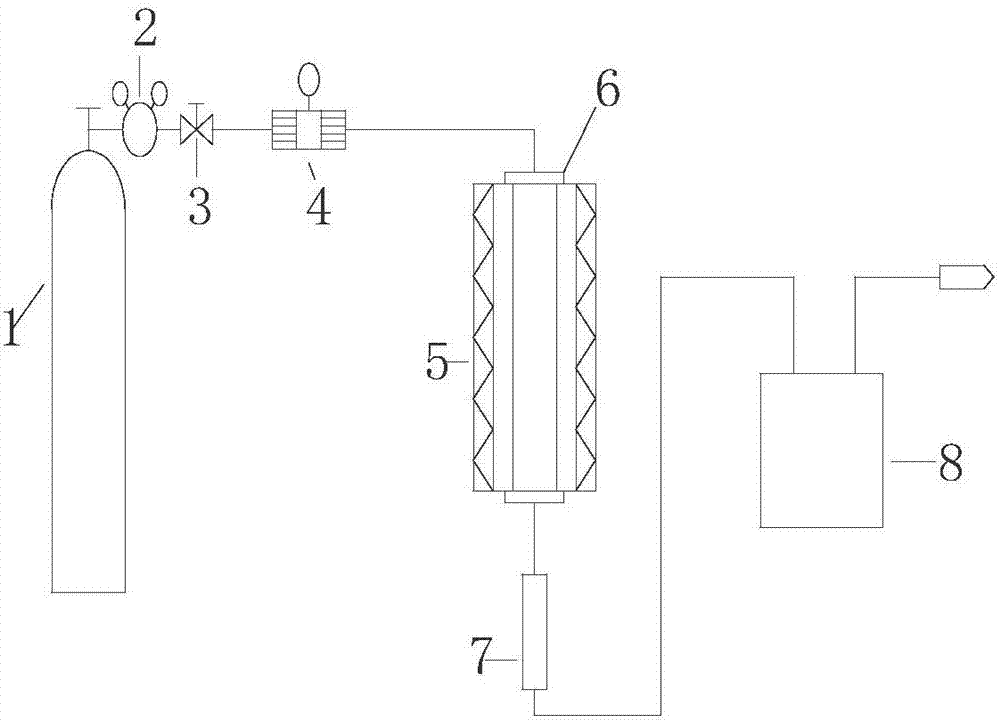

Method used

Image

Examples

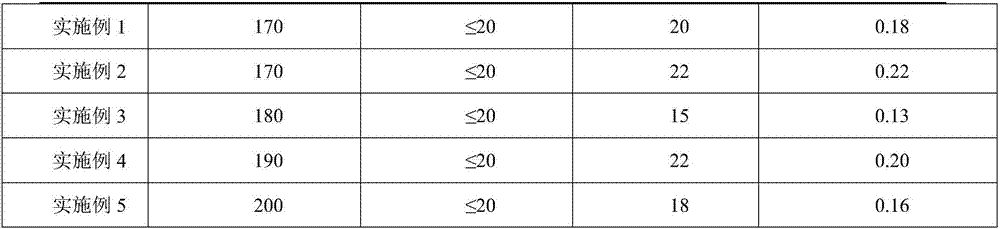

Embodiment 1

[0029] 96g γ-Al 2 o 3 with 4gSiO 2 After mixing, put it into a ball mill and mill it for 7 hours, take out the silicon-aluminum mixture, add 12g of distilled water and 3g of graphite into it and mix it evenly. The mixed material was put into a tablet machine for tablet molding, and the shaped precursor was put into a muffle furnace for calcination at 1100° C. for 3 h.

[0030] Take 60g of the carrier and soak it in 100mL of nitric acid with a concentration of 0.5mol / L for 3h. The soaked carrier was dried at 120°C for 2 h in a forced air drying oven. Mix 112g of copper nitrate trihydrate, 68g of zinc nitrate hexahydrate, 39g of manganese nitrate solution (50% by mass fraction) and 150ml of water into a beaker, and fully dissolve at 70°C. The acid-leached support is then added to the impregnation solution. Place the beaker in an ultrasonic generator for ultrasonic impregnation, the ultrasonic power is 200W, the temperature is controlled at 70°C, and the impregnation is 30mi...

Embodiment 2

[0032] 97g γ-Al 2 o 3 with 3gSiO 2 After mixing, put it into a ball mill and mill it for 8 hours, take out the silicon-aluminum mixture, add 13g of distilled water and 4g of graphite into it, and mix them evenly. The mixed material was put into a tablet machine for tablet molding, and the shaped precursor was put into a muffle furnace for calcination at 1000° C. for 5 h.

[0033] Take 60g of the carrier and soak it in 100mL of nitric acid with a concentration of 0.8mol / L for 3h. The soaked carrier was dried at 120°C for 2 h in a forced air drying oven. Mix 130g of copper nitrate trihydrate, 88g of zinc nitrate hexahydrate, 64g of manganese nitrate solution (50% by mass fraction) and 150ml of water into a beaker, and fully dissolve at 70°C. The acid-leached support is then added to the impregnation solution. The beaker was placed in an ultrasonic generator for ultrasonic impregnation, the ultrasonic power was 250W, the temperature was controlled at 65°C, and the impregnati...

Embodiment 3

[0035] 97g γ-Al 2 o 3 with 3gSiO 2 After mixing, it was put into a ball mill for ball milling for 8 hours, and the silicon-aluminum mixture was taken out, and 14 g of distilled water and 3 g of graphite were added thereto and further mixed evenly. The mixed material was put into a tablet machine for tablet molding, and the shaped precursor was put into a muffle furnace for calcination at 1050° C. for 4 h.

[0036] Take 60g of the carrier and soak it in 100mL of nitric acid with a concentration of 0.4mol / L for 3h. The soaked carrier was dried at 120°C for 2 h in a forced air drying oven. Mix 84g of copper nitrate trihydrate, 82g of zinc nitrate hexahydrate, 60g of manganese nitrate solution (50% by mass fraction) and 150ml of water into a beaker, and fully dissolve at 70°C. The acid-leached support is then added to the impregnation solution. The beaker was placed in an ultrasonic generator for ultrasonic impregnation, the ultrasonic power was 360W, the temperature was cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com