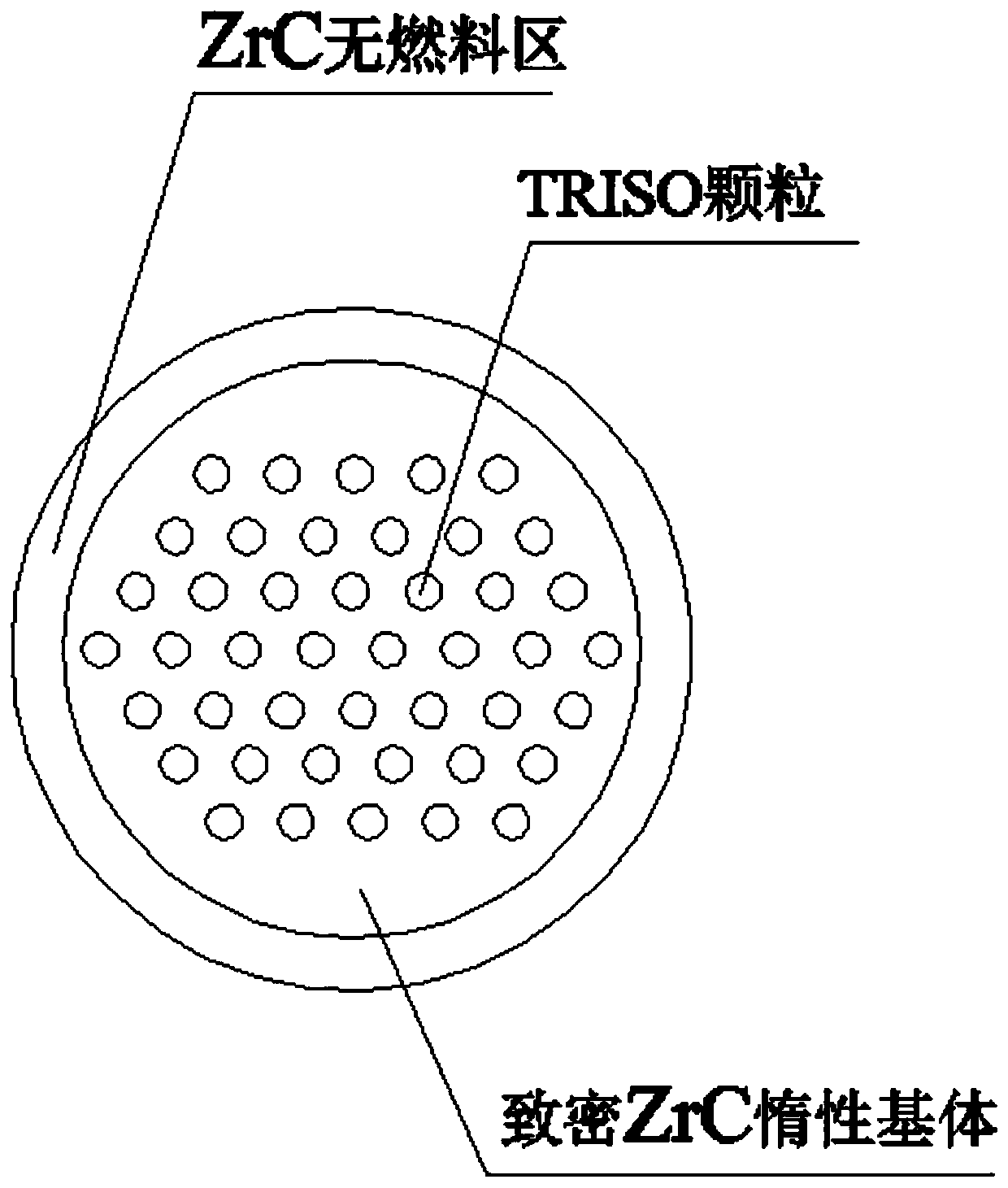

A kind of ZRC inert base dispersed pellet nuclear fuel and its preparation method and application

A kind of nuclear fuel and inert technology, which is applied in the direction of reactor fuel material, nuclear engineering, nuclear power generation, etc., can solve the problems of affecting the safety of reactors and the decline of fault-tolerant performance of pellet accidents, so as to achieve wide application prospects, improve fault-tolerant performance of accidents, and closely integrate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

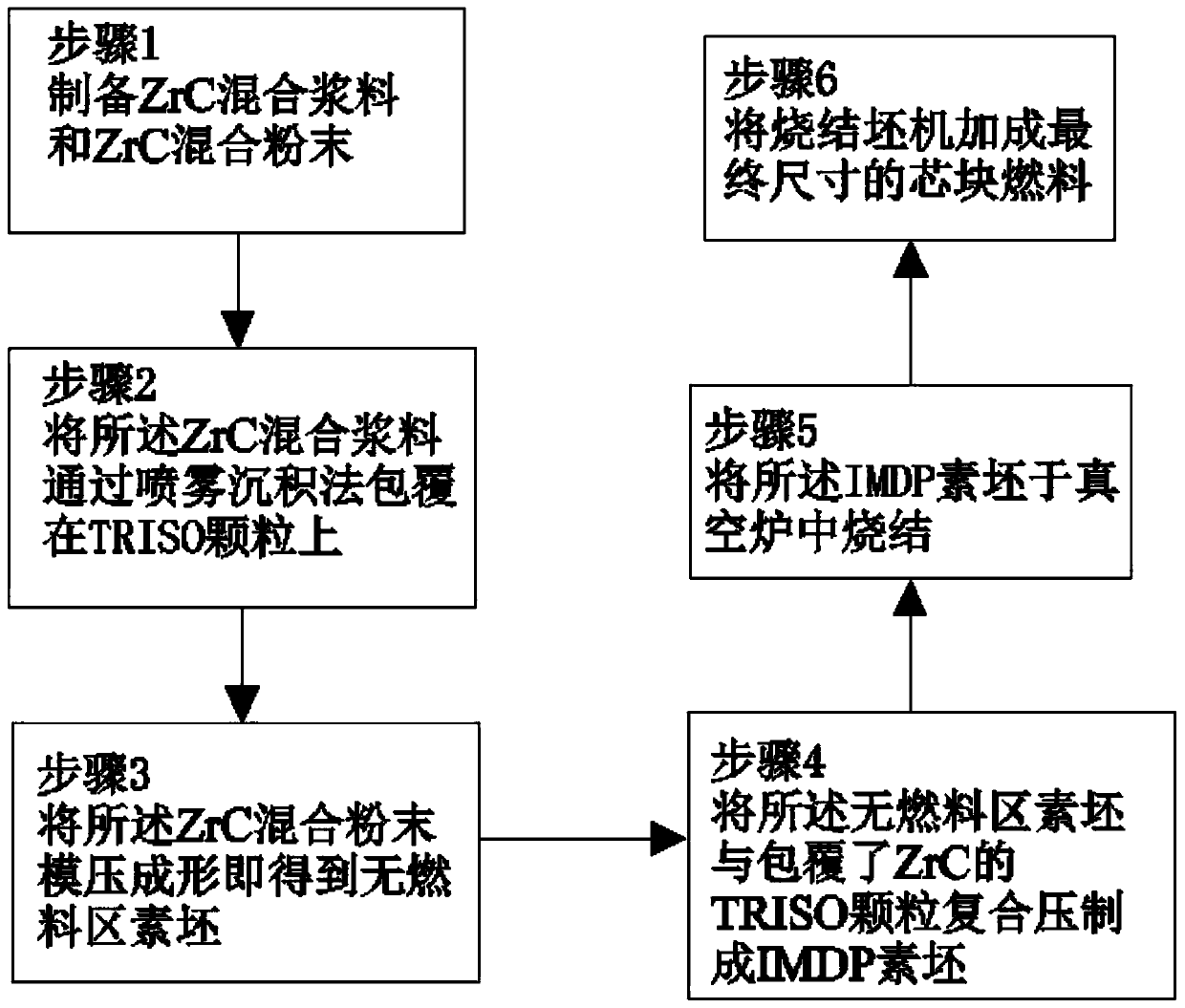

[0057] A method for preparing ZrC inert base dispersed pellet nuclear fuel, comprising the following steps:

[0058] Step 1: Weigh each powder according to the following specifications and proportions: ZrC, 200nm, 95wt.%; 5wt% Si. Mix the above powder with an equal amount of alcohol, put it into a nylon ball mill jar, use zirconia balls as the grinding balls, and have a ball-to-material ratio of 3:1, and mill for 24 hours to obtain ZrC slurry. The slurry was divided into equal parts, one part was used to coat TRISO particles (different fuel cores); the other part was dried at 80°C for 24 hours, and ZrC mixed powder was obtained after sieving.

[0059] Step 2: Coating ZrC mixed slurry on TRISO particles by spray deposition method. The TRISO pellets were rolled on a shaker and subjected to a temperature of 70°C. The ZrC slurry prepared in step 1 was used to form a mist slurry by a spray generator, and the ZrC powder was deposited on the surface of the TRISO particles. By adju...

Embodiment 2

[0067] A method for preparing ZrC inert base dispersed pellet nuclear fuel, comprising the following steps:

[0068] Step 1: Weigh each powder according to the following specifications and proportions: ZrC, 200nm, 95wt.%; 5wt% Si. Mix the above powder with an equal amount of alcohol, put it into a nylon ball mill jar, use zirconia balls as the grinding balls, and have a ball-to-material ratio of 3:1, and mill for 24 hours to obtain ZrC slurry. The slurry was divided into equal parts, one part was used to coat TRISO particles (different fuel cores); the other part was dried at 80°C for 24 hours, and ZrC mixed powder was obtained after sieving.

[0069] Step 2: Coating ZrC mixed slurry on TRISO particles by spray deposition method. The TRISO pellets were rolled on a shaker and subjected to a temperature of 70°C. The ZrC slurry prepared in step 1 was used to form a mist slurry by a spray generator, and the ZrC powder was deposited on the surface of the TRISO particles. By adju...

Embodiment 3

[0077] A method for preparing ZrC inert base dispersed pellet nuclear fuel, comprising the following steps:

[0078] Step 1: Weigh each powder according to the following specifications and proportions: 95wt.% ZrC, 200nm; 5wt% VC. Add polyethyleneimine accounting for 1% of the total mass of sintering aid and zirconium carbide powder as a dispersant, mix the above powder with an equal amount of alcohol, and put it into a nylon ball mill jar. The grinding balls are zirconia balls, and the ball-to-material ratio is 3: 1. Ball mill for 24 hours to obtain ZrC slurry. The slurry was divided into equal parts, one part was used to coat TRISO particles (different fuel cores); the other part was dried at 80°C for 24 hours, and ZrC mixed powder was obtained after sieving.

[0079] Step 2: Coating ZrC mixed slurry on TRISO particles by spray deposition method. The TRISO pellets were rolled on a shaker and subjected to a temperature of 70°C. The ZrC slurry prepared in step 1 was used to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com