Composite aerogel material and preparation method, multiple recycling method, multifunctional composite aerogel material and application thereof

A composite airgel and multi-functional technology, applied in the direction of airgel preparation, chemical instruments and methods, organic compound/hydride/coordination complex catalyst, etc., can solve complex steps and do not involve post-treatment of adsorbent materials Problems, difficult to control and other problems, to achieve the effect of good adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

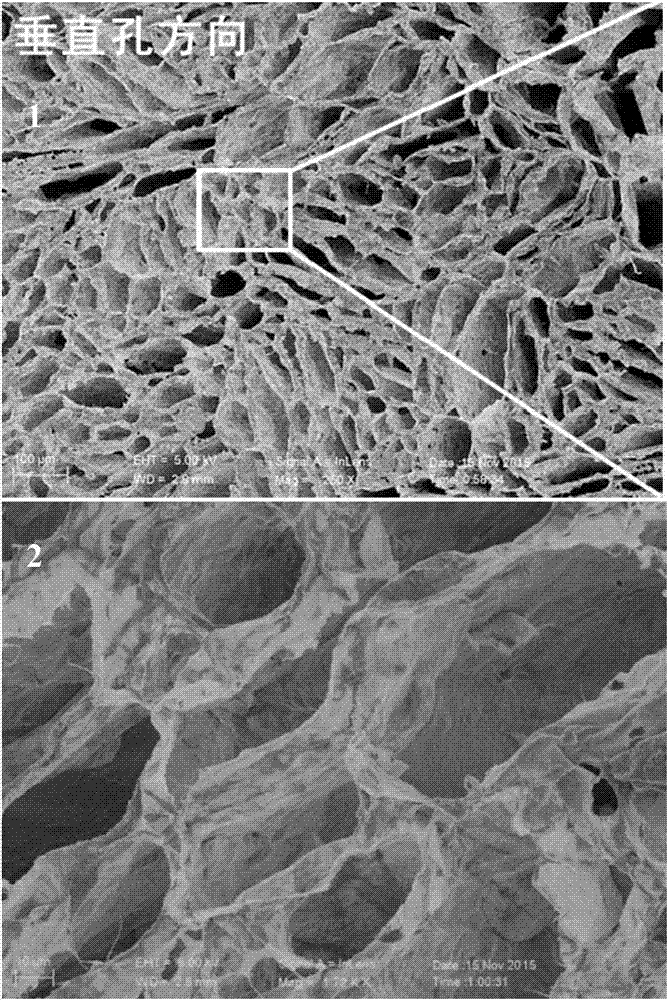

[0060] The invention provides a kind of preparation method of composite airgel material, comprises the following steps:

[0061] 1) mixing the nanowire and the water-soluble polymer aqueous solution to obtain a mixed solution;

[0062] 2) The mixed solution obtained in the above steps is oriented frozen, and then freeze-dried to obtain a composite airgel material.

[0063] The selection and ratio of raw materials in the above-mentioned preparation method of the present invention, as well as the corresponding optimization principles, etc., if not specified, correspond to the selection and ratio of raw materials in the aforementioned composite airgel material, and the corresponding optimization principles, etc., in This will not repeat them one by one.

[0064] In the invention, firstly, the nanowire and the aqueous solution of the water-soluble high molecular polymer are mixed to obtain a mixed solution.

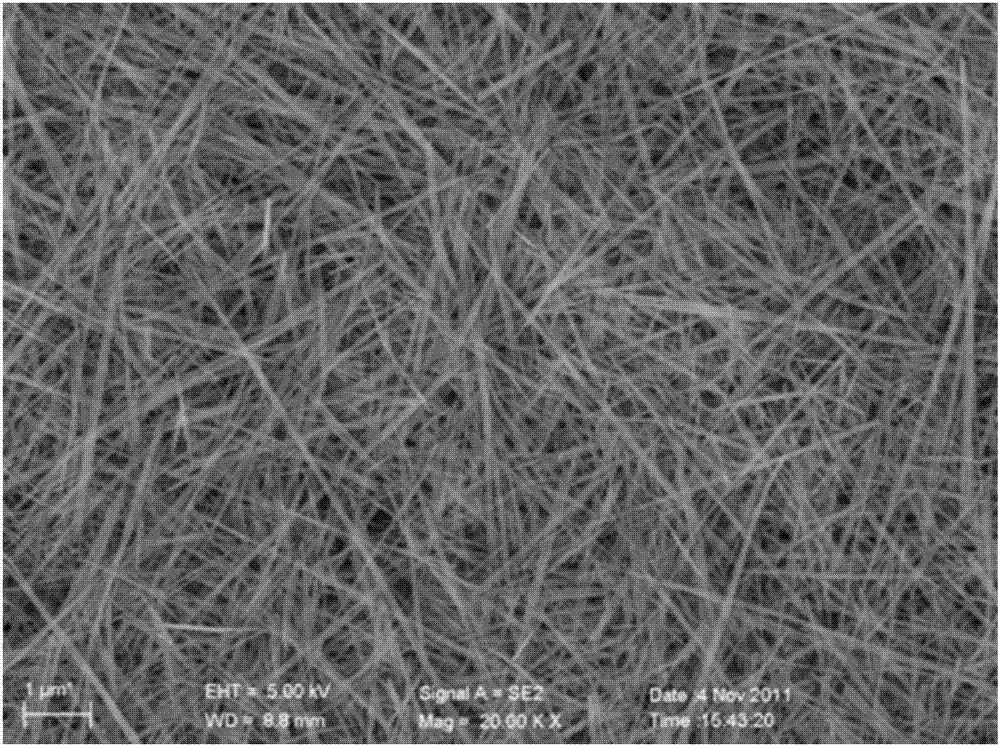

[0065] In the present invention, the source of the nanowires is not pa...

Embodiment 1

[0108] Preparation of sodium alginate-xonotlite nanowire composite airgel material:

[0109] Preparation of sodium alginate solution:

[0110] Weigh 5.0g sodium alginate powder in a 250ml beaker, and measure 245ml deionized water in the beaker, use mechanical stirring, 300rpm, 12h, finally obtain a uniform 2% (20mg / ml) sodium alginate solution, place The refrigerator freezer is ready for use.

[0111] Preparation of xonotlite nanowires:

[0112] Weigh 23.615g of calcium nitrate tetrahydrate into a 250ml beaker, measure 200mL of deionized water into the beaker, and stir for 20min to obtain a clear solution. Weigh 28.42g of sodium metasilicate nonahydrate into a 500ml beaker, add 200mL of deionized water, and stir for 20min with a magnet to obtain a clear solution. Under the condition of vigorous stirring, slowly drop the calcium nitrate tetrahydrate solution into the sodium silicate solution to obtain a white emulsion, continue to stir vigorously for 1 hour, then move the wh...

Embodiment 2

[0127] Sodium alginate-xonotlite airgel material adsorption of heavy metal ions:

[0128] 25 mL of solutions with concentrations of ferric ions, copper ions, barium ions, and lead ions at a concentration of 0.1 M were respectively configured in a 50 mL beaker. The airgel material obtained by the freeze-drying method in Example 1 was equally divided into four parts, and put into the beakers filled with four kinds of metal ion solutions respectively, and the solution was stirred slowly, and the adsorption time was 1.5 h. And take out 0.5ml of the sample solution every 5min, 15min, 45min, and 90min respectively, and conduct the inductively coupled plasma concentration test.

[0129] The adsorption process of the sodium alginate-xonotlite composite airgel material in Example 2 of the present invention was detected and characterized.

[0130] see Figure 4 , Figure 4 It is a photograph of the appearance of the airgel material after the sodium alginate-xonotlite composite airgel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com