An inert atmosphere granulation system

An inert atmosphere and inert gas technology, applied in the field of powder material process processing equipment, can solve problems such as granulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

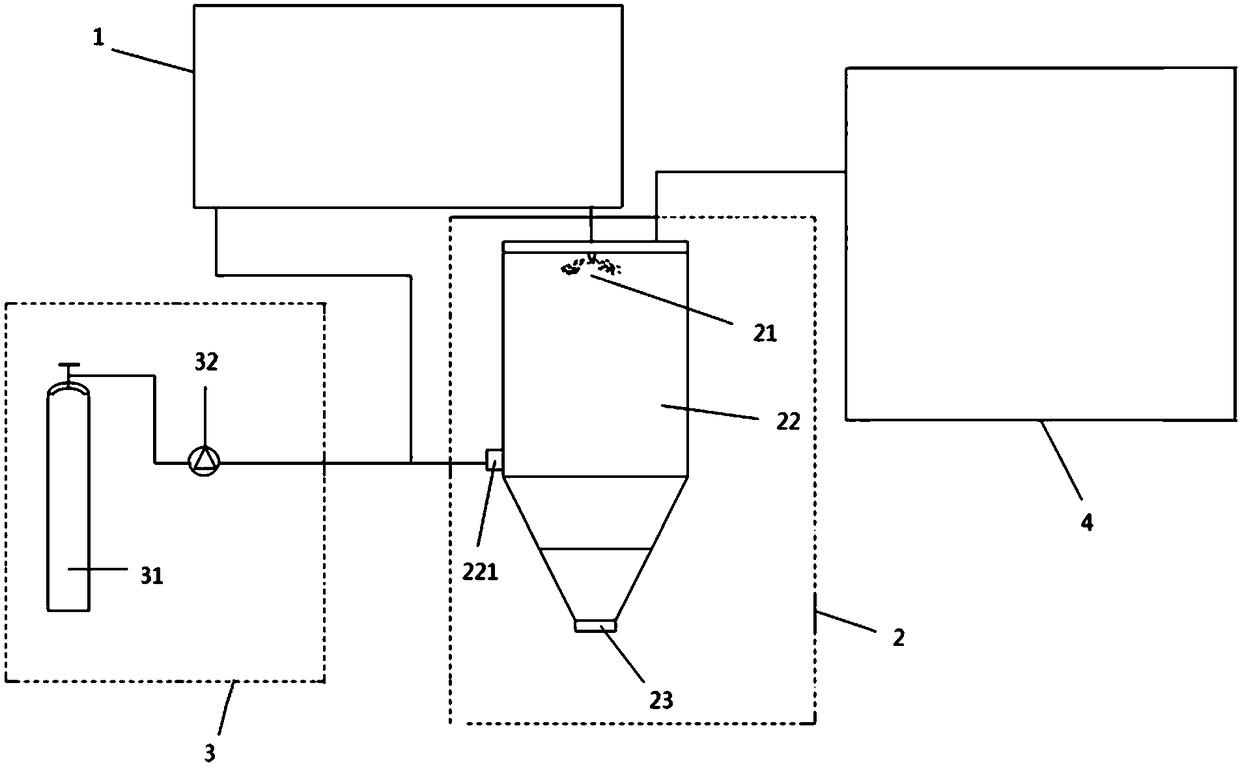

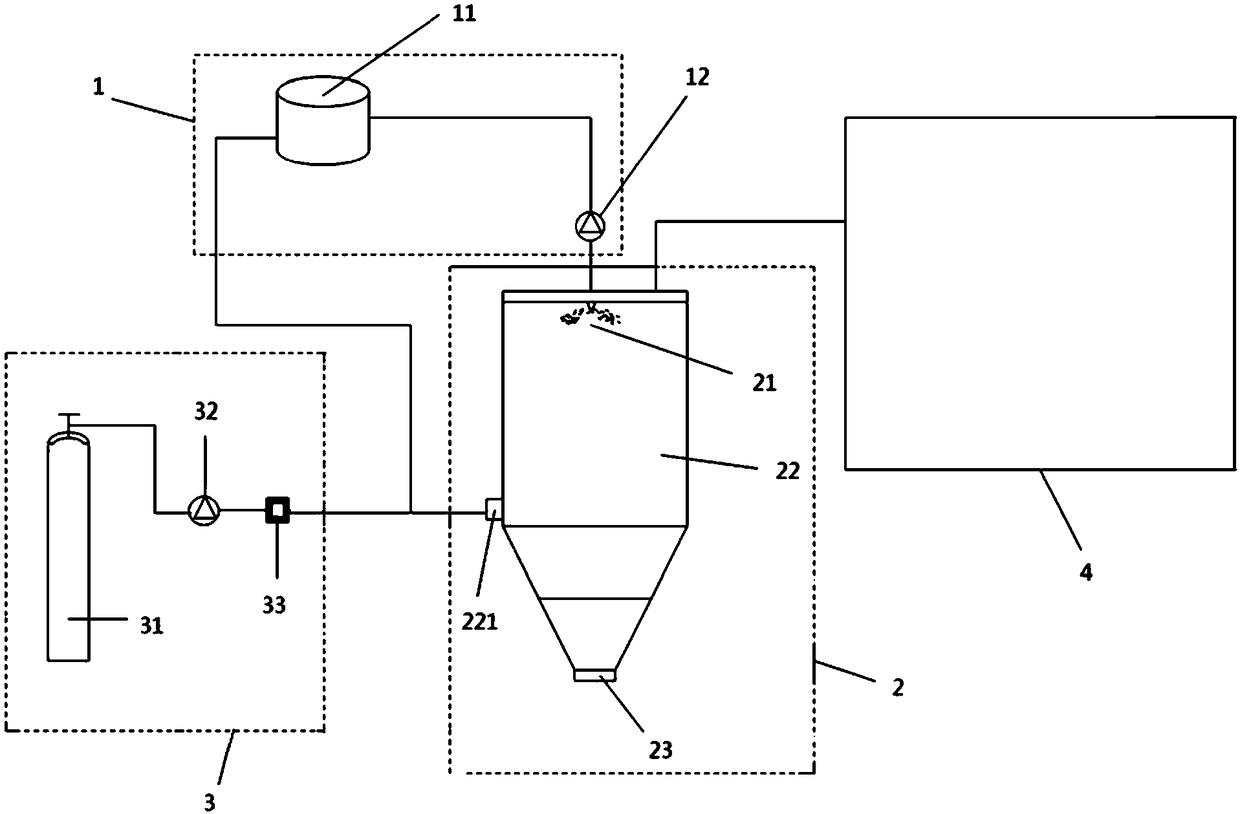

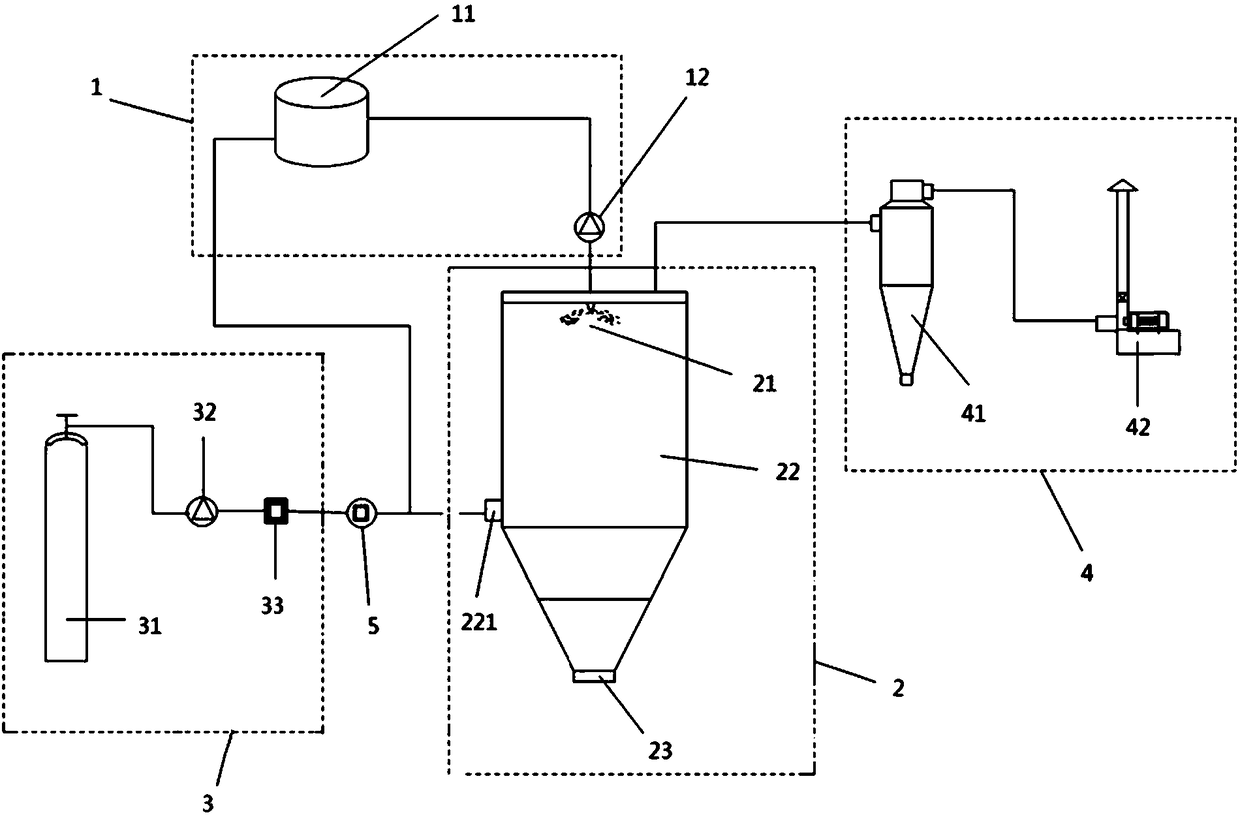

Embodiment 1

[0042] See eg image 3 In the shown inert atmosphere granulation system, in this specific embodiment, the inert gas source uses 99.999% high-purity argon as the protective gas, and the gas purification device uses copper catalyst gas purification equipment, and connects the feeding system and granulation system respectively. system, exhaust system. Ensure that the water and oxygen index is less than 10ppm, put 20 kg of anhydrous lanthanum bromide powder in the supply tank, raise the temperature to 50°C above the melting point of lanthanum bromide, keep the lanthanum bromide in a liquid state, and then spray it into the inert airflow from the nozzle In the protected condensation tower, adjust the aperture of the nozzle and the flow rate of the cooling air flow to obtain lanthanum bromide particles with a uniform particle size of -10 mesh.

Embodiment 2

[0044] See eg image 3 In the shown inert atmosphere granulation system, in this specific embodiment, the inert gas source uses 99.999% high-purity argon as the protective gas, and the gas purification device uses copper catalyst gas purification equipment, and connects the feeding system and granulation system respectively. system, exhaust system. To ensure that the water and oxygen index is less than 10ppm, put 20 kg of anhydrous cerium bromide powder into the supply tank, raise the temperature to 50°C above the melting point of cerium bromide, keep the cerium bromide in a liquid state, and then spray it into an inert airflow from the nozzle In the protected condensation tower, adjust the aperture of the nozzle and the flow rate of the cooling air flow to obtain cerium bromide particles with a uniform particle size of -10 mesh.

Embodiment 3

[0046] See eg image 3 In the shown inert atmosphere granulation system, in this specific embodiment, the inert gas source uses 99.999% high-purity argon as the protective gas, and the gas purification device uses copper catalyst gas purification equipment, and connects the feeding system and granulation system respectively. system, exhaust system. Ensure that the water oxygen index is less than 10ppm, put 20 kg of anhydrous lanthanum bromide powder and 1.003 kg of cerium bromide powder in the supply tank, raise the temperature to 50 °C above the melting point of lanthanum bromide, and make lanthanum bromide, bromide The cerium remains in a liquid state, and then sprayed into the condensation tower protected by the inert gas flow through the nozzle, and the aperture of the nozzle and the flow rate of the cooling air flow are adjusted to obtain cerium bromide mixture particles with a uniform particle size of -10 mesh and a content of 5% cerium-lanthanum bromide.

[0047] In su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com