Constant-temperature electromagnetic purifying assembly and constant-temperature electromagnetic purifying filter

An electromagnetic purification and filter technology, which is applied in chemical instruments and methods, filtration circuits, filtration and separation, etc., can solve the problems of high surface temperature of mandrels, reduce combustion heat efficiency, increase resistance, etc., to meet work requirements and work. Stable and reliable, high power efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to clearly illustrate the technical features of this solution, the specific implementation of the present invention will be further described below according to the accompanying drawings.

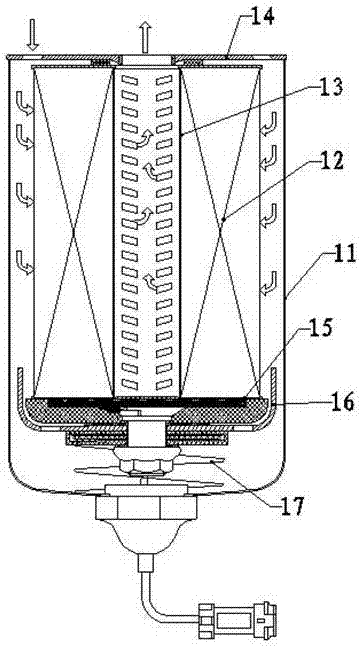

[0018] Such as figure 1 , figure 2 As shown, a constant temperature electromagnetic purification filter includes a filter housing 11, a filter element 12, an inner support 13 of the filter element, an upper gusset 14, a lower gusset 15 and a constant temperature electromagnetic purification assembly 16, and a constant temperature electromagnetic purification assembly 16 Installed in the filter housing 11, its heating surface is in contact with the lower buckle plate 15, and a spring 17 is arranged between the constant temperature electromagnetic purification assembly 16 and the filter housing 11.

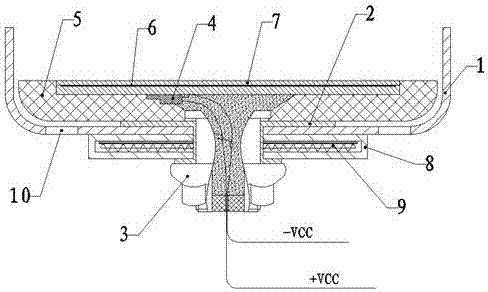

[0019] The constant temperature electromagnetic purification assembly 16 includes an electromagnet 1 , a constant temperature heater, a magnetic insulation body 2 , an electroma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com