Equivalent combustion system and control method based on mixture gas dilution

A technology of combustion system and control method, applied in electrical control, fuel injection control, charging system, etc., can solve problems such as unfavorable engine thermal efficiency and dynamic performance, increase fuel supply volume flow, unfavorable combustion process organization, etc., to improve fuel consumption. efficiency, improve thermal efficiency, increase the effect of intake pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

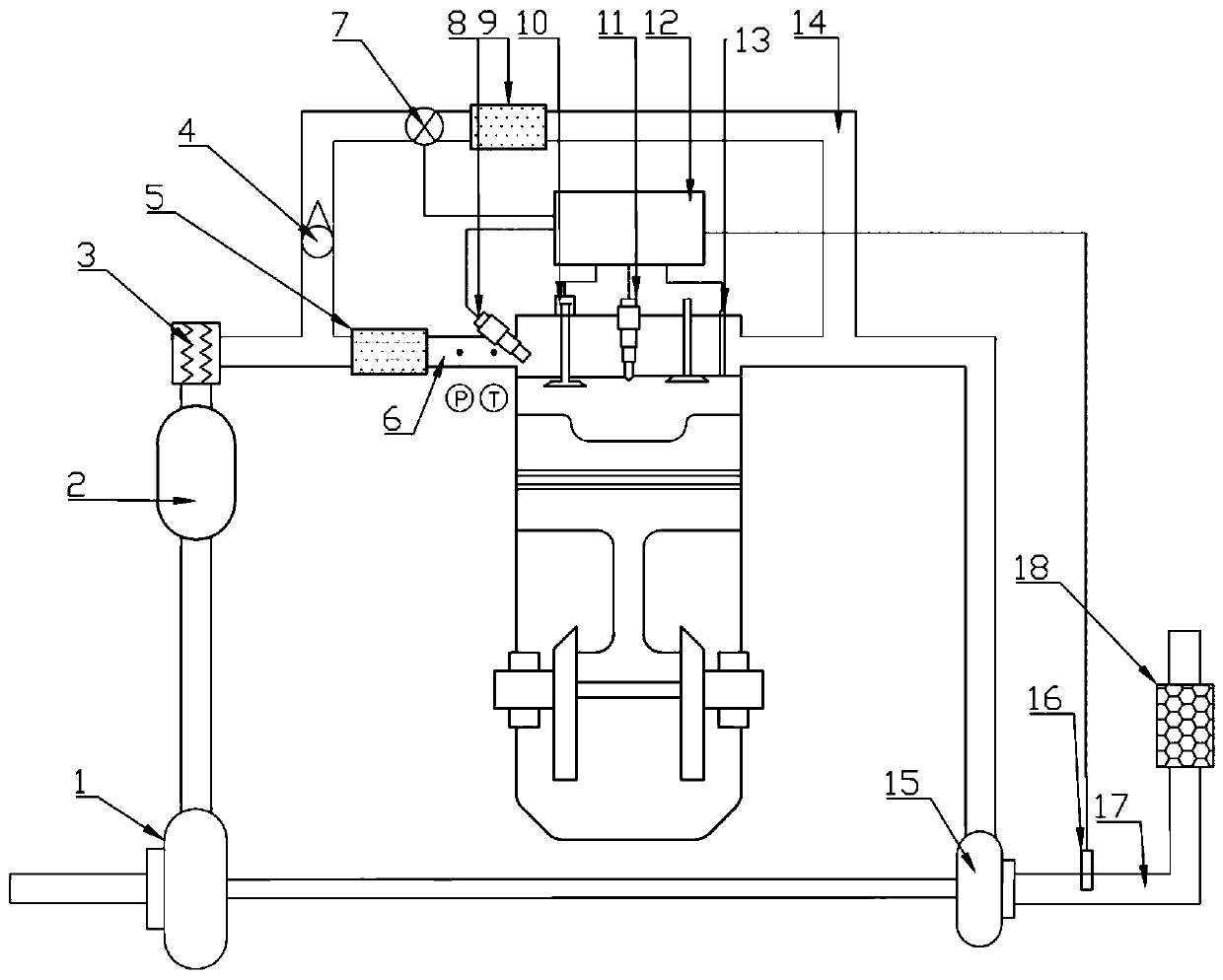

[0032] In this embodiment, an engine with a high geometric compression ratio (18:1) is used, the direct injection fuel in the cylinder is polyoxymethylene dimethyl ether (PODE), and commercial gasoline with an RON octane value of 95 is injected into the airway.

[0033] Step 1, the engine electronic control unit 12 respectively reads the speed signal of the sensor installed on the crankshaft of the engine, the position signal of the sensor installed on the accelerator pedal, and judges the load of the engine according to the read signals;

[0034] Step 2. If the judgment result of step 1 is cold start and idling condition, use polyoxyl dimethyl ether (PODE) direct injection injector 11 to carry out 100% polyoxyl dimethyl ether (PODE) in-cylinder Direct injection;

[0035] Step 3. If the judgment result of step 1 is a small load condition: the speed is 1500r / min, the load is 0.20MPaIMEP, the electronic control unit 12 reads the calibration MAP, and then outputs a control signal...

Embodiment 2

[0040] In this embodiment, an engine with a high geometric compression ratio (18:1) is used, the direct injection fuel in the cylinder is polyoxymethylene dimethyl ether (PODE), and commercial gasoline with an RON octane value of 95 is injected into the airway.

[0041] Step 1, the engine electronic control unit 12 respectively reads the speed signal of the sensor installed on the crankshaft of the engine, the position signal of the sensor installed on the accelerator pedal, and judges the load of the engine according to the read signals;

[0042] Step 2. If the judgment result of step 1 is cold start and idling condition, use polyoxyl dimethyl ether (PODE) direct injection injector 11 to carry out 100% polyoxyl dimethyl ether (PODE) in-cylinder Direct injection;

[0043] Step 3. If the judgment result of step 1 is a small load condition: the speed is 1500r / min, the load is 0.35MPaIMEP, the electronic control unit 12 reads the calibration MAP, and then outputs the control sign...

Embodiment 3

[0048] In this embodiment, an engine with a high geometric compression ratio (18:1) is used, the direct injection fuel in the cylinder is polyoxymethylene dimethyl ether (PODE), and commercial gasoline with an RON octane value of 95 is injected into the airway.

[0049] Step 1, the engine electronic control unit 12 respectively reads the speed signal of the sensor installed on the crankshaft of the engine, the position signal of the sensor installed on the accelerator pedal, and judges the load of the engine according to the read signals;

[0050] Step 2. If the judgment result of step 1 is cold start and idling condition, use polyoxyl dimethyl ether (PODE) direct injection injector 11 to carry out 100% polyoxyl dimethyl ether (PODE) in-cylinder Direct injection;

[0051] Step 3. If the judgment result of step 1 is a small load condition: the speed is 1500r / min, the load is 0.5MPaIMEP, the electronic control unit 12 reads the calibration MAP, and then outputs a control signal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com