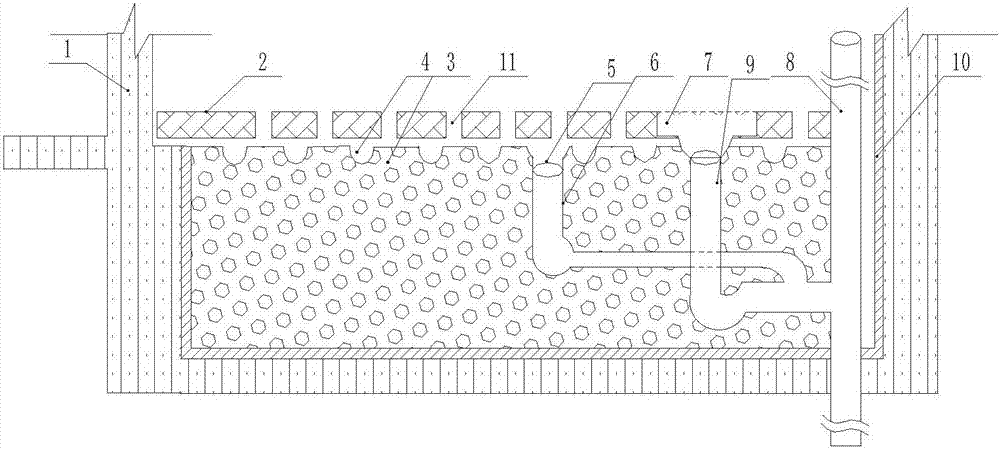

Foamed cement backfilling structure of caisson type toilet and backfilling method thereof

A technology for cement foaming and toilets, which is applied to building components, building structures, and other household appliances. It can solve the problems of unsatisfactory hydrophobic effect, complex pipeline layout, and difficult foaming and backfilling, so as to improve water resistance and heat insulation. and temperature insulation effect, the foaming process is simple, and the overall effect is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

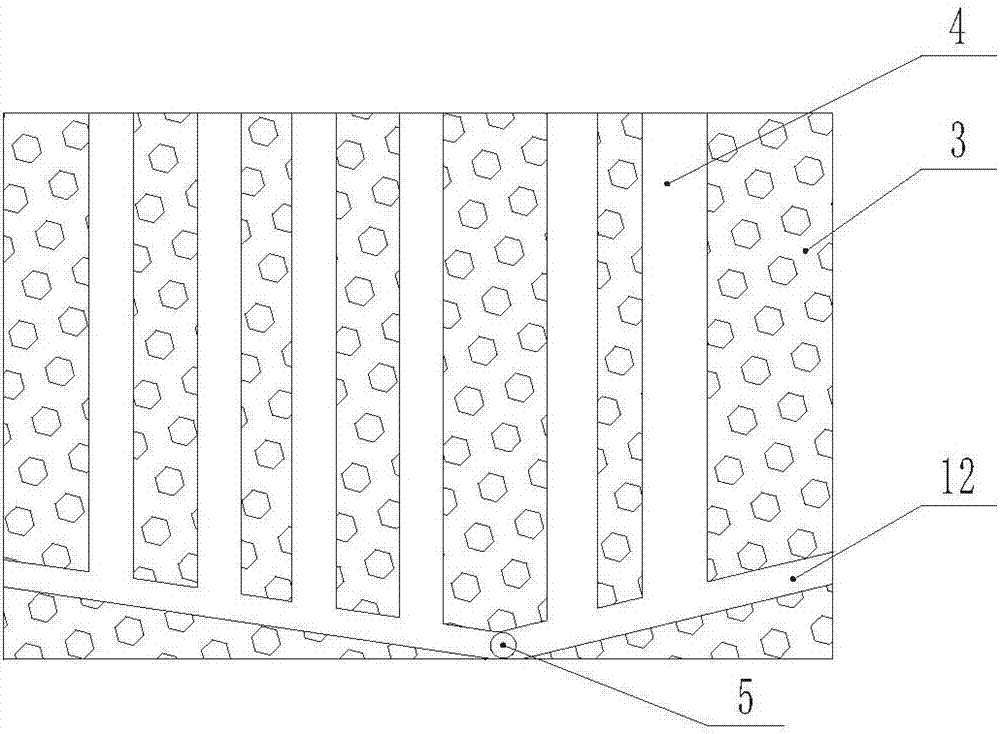

[0073] Include the following steps:

[0074] Step (1): Routing pipes:

[0075] Set the primary drainage pipe, secondary drainage pipe and main downpipe;

[0076] Step (2): Foaming of the lightweight foamed cement

[0077] The foamed concrete is obtained by foaming in the following parts by weight ratio:

[0078]

[0079]

[0080] The cement is Portland cement.

[0081] The water retaining agent is polyacrylamide.

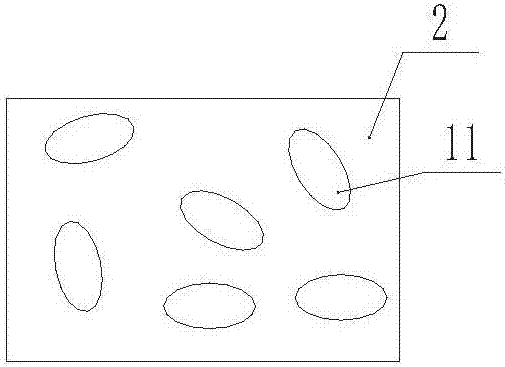

[0082] Dissolve the foaming aid and Yuanming powder in water, and foam at a speed of 100-110r / min to 500-550% of the volume of the added water, then add water-repellent agent, ash calcium, and water-retaining agent, and then stir Add cement and continue to stir to obtain the foamed cement filling material;

[0083] Step (3): backfilling the foamed cement filling material obtained by foaming in step (2) into the space in step (1), finishing the surface to form the foamed cement concrete layer;

[0084] Step (4): installing the toilet and the tile surface ...

Embodiment 2

[0088] Compared with Example 1, the difference is that the foamed concrete is obtained by foaming in the following parts by weight:

[0089]

[0090]

[0091]The cement is Portland cement.

[0092] The water retaining agent is polyacrylamide.

[0093] The material density of the foamed concrete layer obtained by backfilling is about 280kg / m 3 .

[0094] The thermal conductivity of the material of the foamed concrete layer obtained by backfilling is 0.12W / (M.K), which can be poured on site and closely integrated with the main project. In addition, the water absorption performance of the material prepared in this example is 5-6 (v / v%), has good waterproof performance, has independent closed air cells and good integrity, and can further improve the waterproof, heat preservation, and Sound insulation and other properties.

Embodiment 3

[0096] Compared with Example 1, the difference is that the foamed concrete is obtained by foaming in the following parts by weight:

[0097]

[0098] The cement is Portland cement.

[0099] The water retaining agent is polyacrylamide.

[0100] The material density of the foamed concrete layer obtained by backfilling is about 290kg / m 3 .

[0101] The thermal conductivity of the material of the foamed concrete layer obtained by backfilling is 0.15W / (M.K), which can be poured on site and closely integrated with the main project. In addition, the water absorption performance of the material prepared in this example is 6-7 (v / v%), has good waterproof performance, has independent closed air cells and good integrity, and can further improve the waterproof, heat preservation, and Sound insulation and other properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com