A method for synergistic hypoeutectic casting Al-Si alloy modification and microalloying

A casting aluminum-silicon alloy and micro-alloying technology, which is applied in the field of aluminum alloys, can solve problems such as serious gas-intake tendency, long metamorphic incubation period, and general metamorphic effect, so as to overcome serious gas-intake tendency, weaken further oxidation, and reduce smelting procedures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

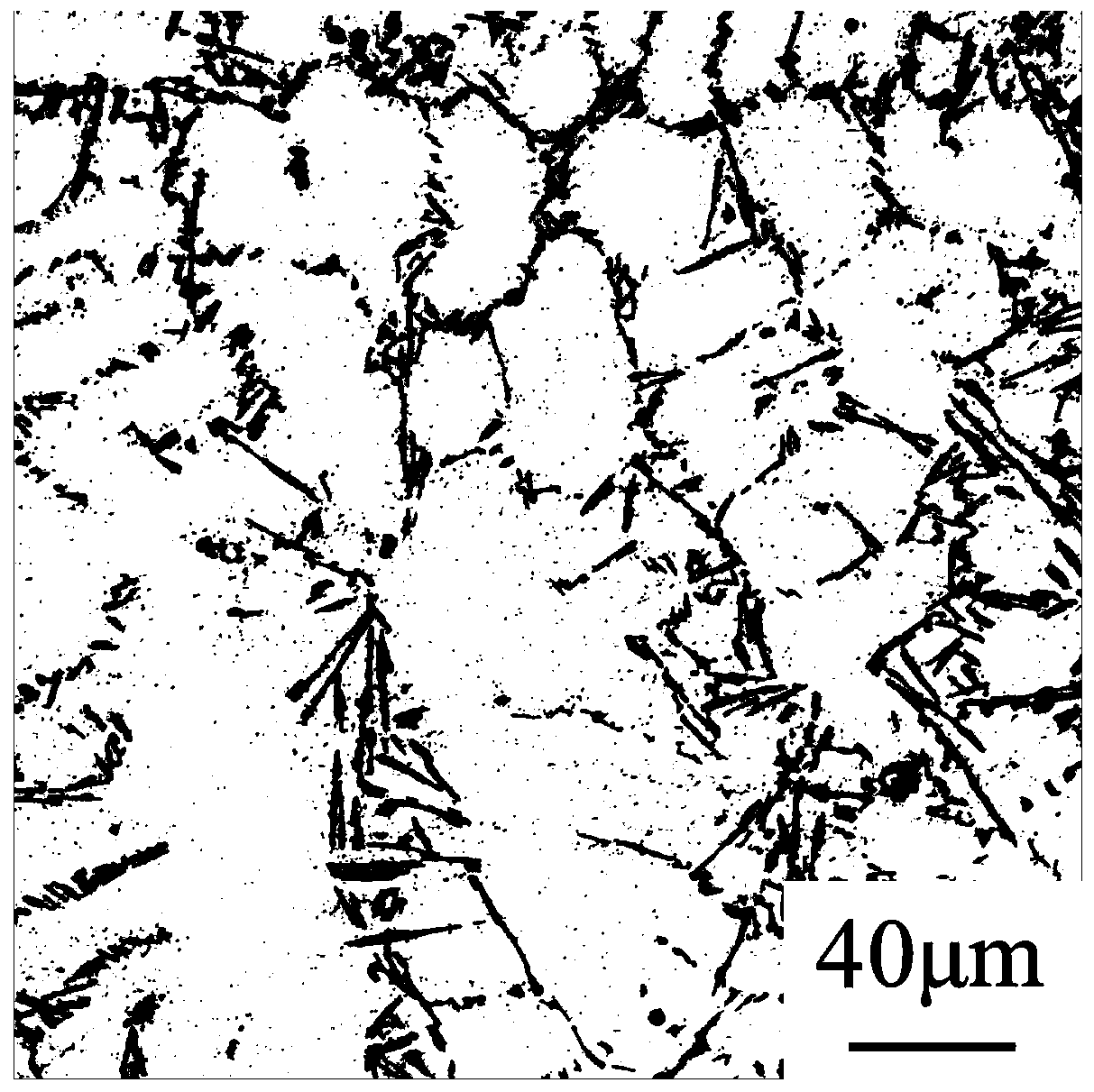

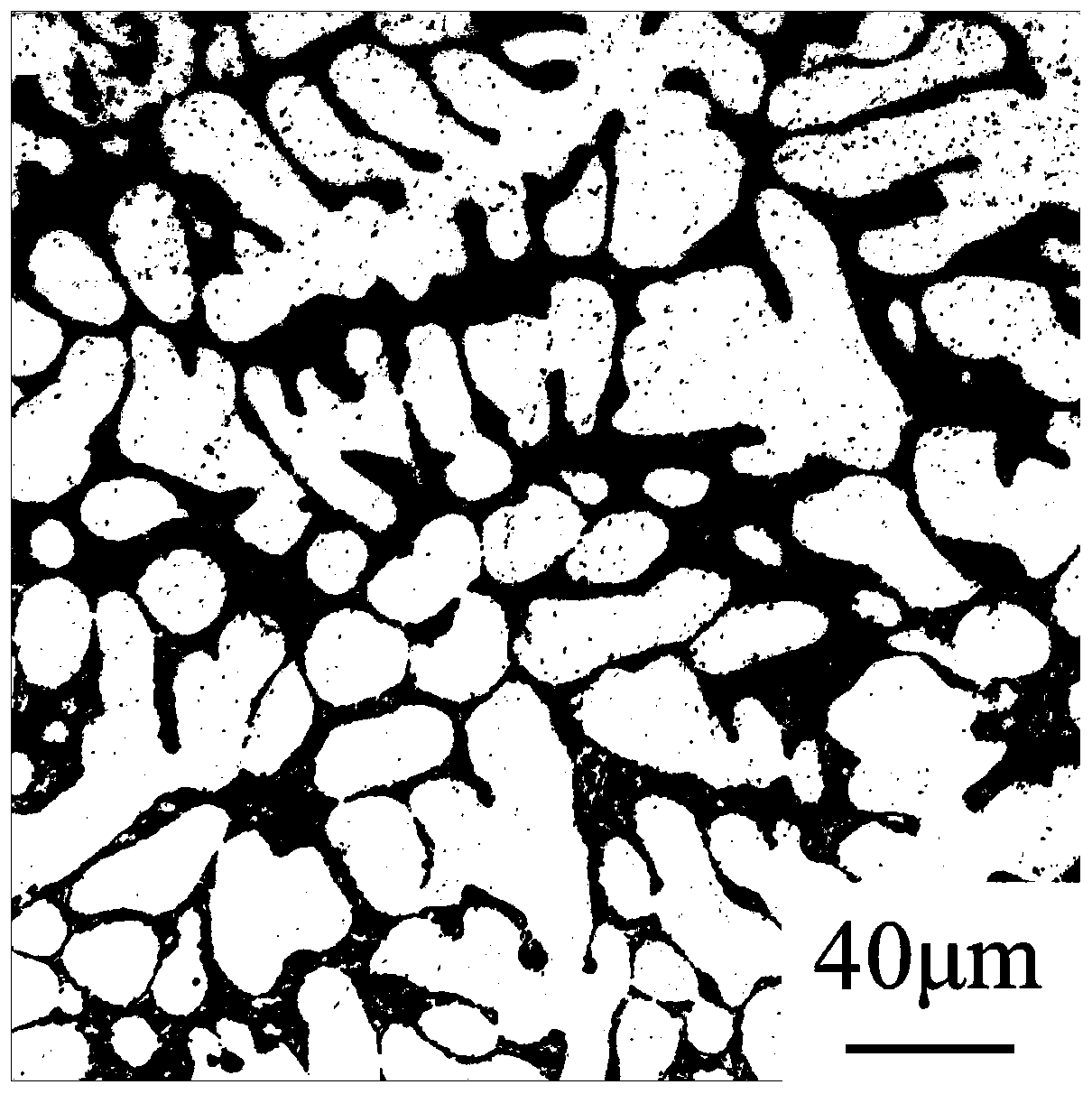

Image

Examples

Embodiment 1

[0025] Embodiment 1: The modification and microalloying methods of the hypoeutectic cast aluminum-silicon alloy in this embodiment are as follows:

[0026] Step 1: In a crucible resistance furnace, melt the dried Al-7Si alloy in a graphite clay crucible at 760°C and keep it warm for 20-30 minutes to obtain a uniform aluminum melt;

[0027] Step 2: Cool the aluminum alloy melt obtained in step 1 to 720°C, and add 0.8% by mass of C 2 Cl 6 Refining, heat preservation for 20-30 minutes, and then skimming;

[0028] Step 3: adding rare earth La to the aluminum alloy melt obtained in step 2 at 730° C., controlling the content of La element in the alloy melt at 0.25-0.35% by mass, adding La element and keeping it warm for 25 minutes;

[0029] Step 4: raising the temperature of the aluminum alloy melt obtained in step 3 to 760° C., adding Mg element, the mass percentage of Mg element in the alloy melt is controlled at 0.65-0.75%, and after adding Mg element, keep the temperature for ...

Embodiment 2

[0033] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the rare earth La is added at 720° C. in step 3, and the mass percentage content of La element in the alloy melt is controlled at 0.2%. After adding La element, the temperature is kept for 20 minutes. Others are the same as in Embodiment 1.

Embodiment 3

[0034] Embodiment 3: The difference between this embodiment and Embodiment 1 is that in step 3, rare earth La is added at 740° C., and the mass percentage content of La element in the alloy melt is controlled at 0.5%. After adding La element, the temperature is kept for 30 minutes. Others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com