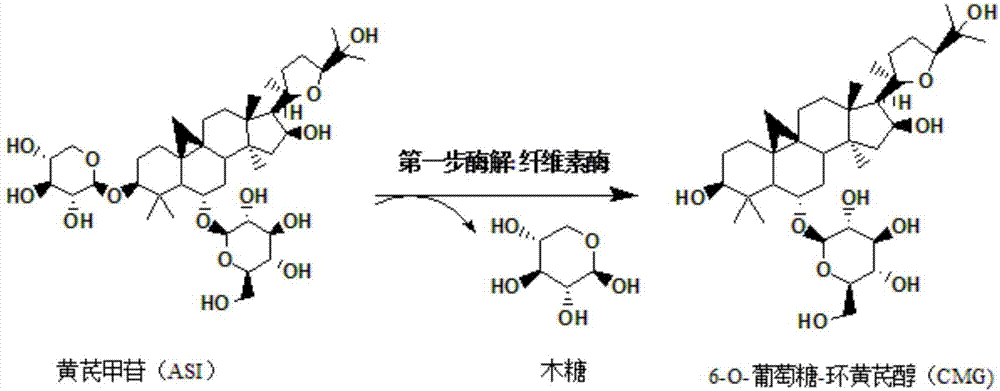

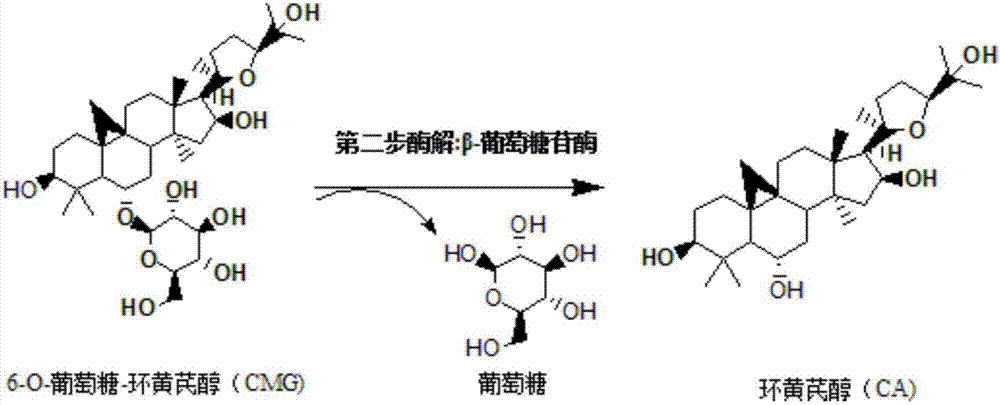

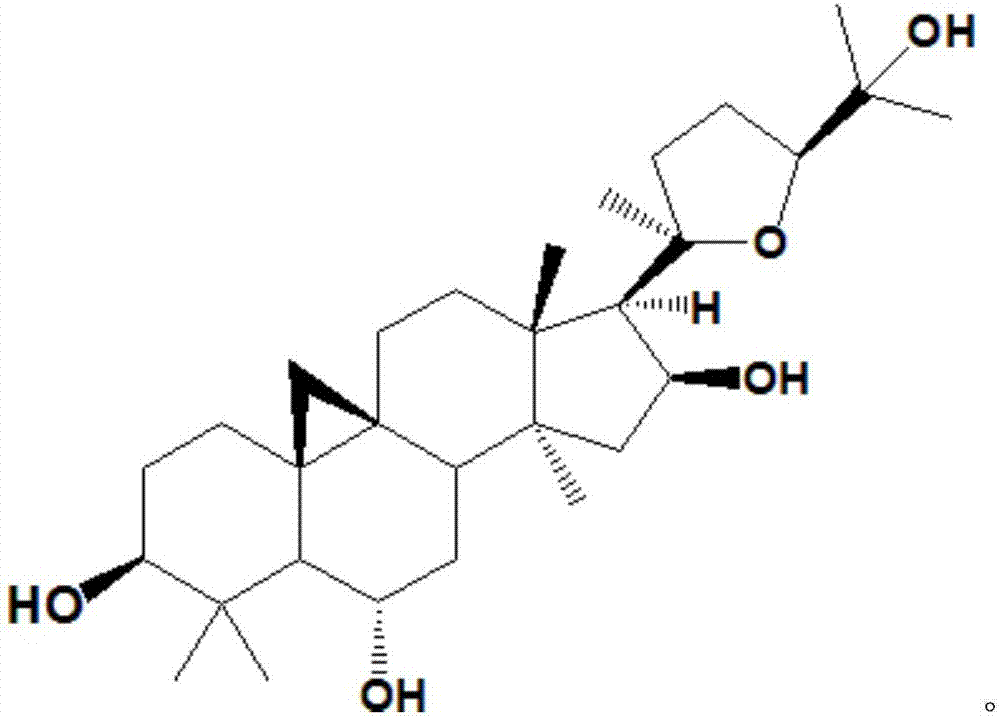

Method for converting astragalosides to prepare cycloastragenol by two-step enzymolysis

A technology of astragaloside IV and cycloastragenol, which is applied in the field of medicine and chemical industry, can solve the problems of three-membered rings that are easy to crack astragalol, and achieve the effects of reduced energy consumption, high purity, and mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Accurately prepare 0.2 mol / L disodium hydrogen phosphate solution and 0.1 mol / L citric acid solution, mix the two solutions at a volume ratio of 1.06:1, and adjust the pH of the buffered saline solution to 5.0 with hydrochloric acid.

[0036] The first step of enzymatic hydrolysis: accurately measure 100mL of enzymatic hydrolysis buffer saline solution and place it in a 250mL beaker, and add 100mg of astragaloside IV with a mass percentage of 10% to it, and heat the system after the substrate astragaloside IV is completely dissolved to 45°C, then add 0.05g of cellulase that has been heated to 45°C into the system, and adjust the pH of the system to 4.6 with hydrochloric acid, and finally place the reaction system on a magnetic heating and stirring instrument at a stirring speed of 200r / min , The temperature is 45 ℃ and fully reacted for 60h. Afterwards, 1 mL of the sample was passed through a 0.22 μm filter membrane and detected by high-performance liquid chromatography...

Embodiment 2

[0041] Accurately prepare 0.2 mol / L disodium hydrogen phosphate solution and 0.1 mol / L citric acid solution, mix the two solutions at a volume ratio of 1.06:1, and adjust the pH of the buffered saline solution to 5.0 with hydrochloric acid.

[0042] The first step of enzymatic hydrolysis: accurately measure 100mL of enzymatic hydrolysis buffer saline solution and place it in a 250mL beaker, and add 100mg of astragaloside IV with a mass percentage of 10% to it, and heat the system after the substrate astragaloside IV is completely dissolved to 50°C, then add 0.05g of cellulase that has been heated to 50°C into the system, and adjust the pH of the system to 5.0 with hydrochloric acid, and finally place the reaction system on a magnetic heating stirring instrument at a stirring speed of 200r / min , The temperature is 50 ℃ and fully reacted for 48h. Afterwards, 1 mL of the sample was passed through a 0.22 μm filter membrane and detected by high-performance liquid chromatography. Th...

Embodiment 3

[0047] Accurately prepare 0.2 mol / L disodium hydrogen phosphate solution and 0.1 mol / L citric acid solution, mix the two solutions at a volume ratio of 1.06:1, and adjust the pH of the buffered saline solution to 5.0 with hydrochloric acid.

[0048] The first step of enzymatic hydrolysis: accurately measure 100mL of enzymatic hydrolysis buffer saline solution and place it in a 250mL beaker, and add 100mg of astragaloside IV with a mass percentage of 10% to it, and heat the system after the substrate astragaloside IV is completely dissolved to 55°C, then add 0.05g of cellulase that has been heated to 55°C into the system, and adjust the pH of the system to 5.5 with hydrochloric acid, and finally place the reaction system on a magnetic heating and stirring instrument at a stirring speed of 200r / min , The temperature is 55 ℃ and fully reacted for 72h. Afterwards, 1 mL of the sample was passed through a 0.22 μm filter membrane and detected by high-performance liquid chromatography...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com