Method for preparing anti-crack log veneer

A log and anti-cracking technology, applied in the field of wood processing, can solve the problems of veneer processing quality impact, paper dust is difficult to remove, paper dust pollutes dyes and bleaching solutions, etc., to improve toughness and fluidity, reduce breakage rate, The effect of improving adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

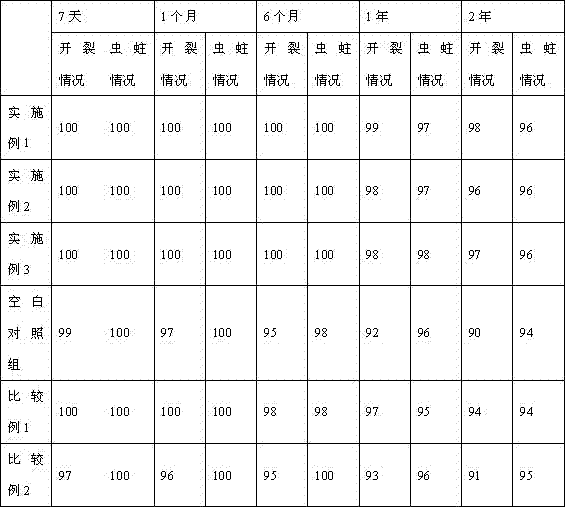

Examples

Embodiment 1

[0029] (1) Dissolve 100g rosin in 1200g solvent ethanol, then add 30g polyethylene glycol 400, adjust the pH of the reaction solution to be 8, heat to reflux reaction for 3 hours, cool to room temperature, remove the solvent by distillation under reduced pressure, and the residue in Vacuum-dried at 55°C, and then ground into 100-mesh powder, which is the modified rosin.

[0030] (2) A kind of anti-crack end capping glue, is made up of A, B two components, and described A component is made up of the component of following parts by weight: polyoxypropylene glycol 25 parts, hydroxymethyl cellulose 5 parts , 2 parts of polyoxyethylene oleate, 1 part of polyoxyethylene polyoxypropylene pentaerythritol ether, 8 parts of montmorillonite and 30 parts of ethyl acetate;

[0031] The B component is composed of the following components in parts by weight: 20 parts of isocyanate, 10 parts of modified rosin and 20 parts of ethyl acetate.

[0032] (3) Logs are cut off, peeled, placed in a c...

Embodiment 2

[0035] (1) Dissolve 100g rosin in 1000g solvent ethanol, then add 40g polyethylene glycol 600, adjust the pH of the reaction solution to 8.5, heat to reflux for 2 hours, cool to room temperature, remove the solvent by distillation under reduced pressure, and the residue in Vacuum-dried at 50°C, and then ground into 80-mesh powder, which is the modified rosin.

[0036] (2) A kind of anti-crack end capping glue, is made up of A, B two components, and described A component is made up of the component of following parts by weight: 30 parts of polyoxypropylene triols, 3 parts of hydroxymethyl cellulose , 1 part of sorbitan fatty acid ester, 2 parts of polyoxyethylene polyoxypropanolamine ether, 5 parts of montmorillonite and 25 parts of ethyl acetate;

[0037] The B component is composed of the following components in parts by weight: 15 parts of isocyanate, 5 parts of modified rosin and 25 parts of ethyl acetate.

[0038] (3) Logs are cut off and peeled, and placed in a cool and ...

Embodiment 3

[0041] (1) Dissolve 100g rosin in 2000g solvent ethanol, then add 20g polyethylene glycol 800, adjust the pH of the reaction solution to be 9, heat to reflux reaction for 4 hours, cool to room temperature, remove the solvent by distillation under reduced pressure, and the residue in Vacuum-dried at 60°C, and then ground into 200-mesh powder, which is the modified rosin.

[0042] (2) A kind of anti-crack end capping glue, is made up of A, B two components, and described A component is made up of the component of following parts by weight: polytetrahydrofuran diol

[0043] (3) Logs are cut off, peeled, placed in a cool and ventilated place and dried until the water content is 55%, and the amount of the anti-cracking sealing glue is 25g / m 2 .

[0044] (4) Apply anti-crack sealing glue to both ends of the log obtained in step (3), and after curing at room temperature for 10 hours, peel and cut into log veneers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com