Efficient medium and low temperature sulfur-containing flue gas denitration device and method based on Fast SCR reaction

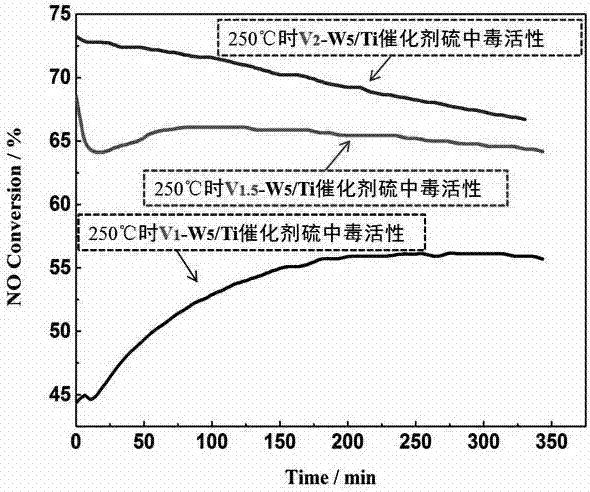

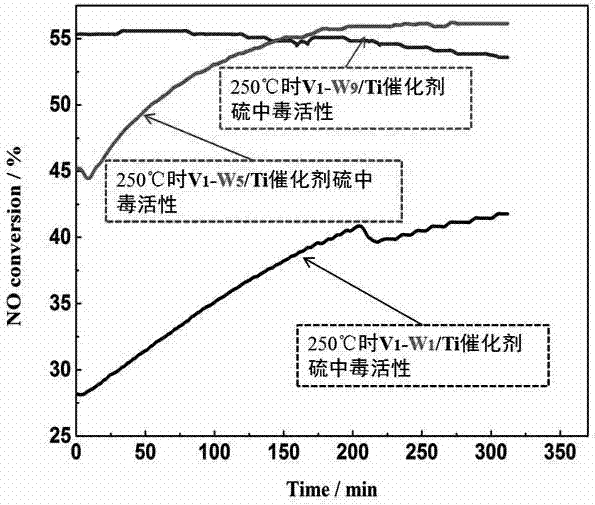

A denitrification and flue gas technology, applied in the field of flue gas denitrification, can solve the problems of sulfur poisoning and low denitration efficiency of low temperature SCR, and achieve the effect of improving the reaction activity, improving the efficiency of low temperature denitration, and saving investment and operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

[0022] Such as figure 1 The high-efficiency denitrification device for medium-low temperature sulfur-containing flue gas based on the Fast SCR reaction is shown. The device can be installed on the exhaust flue of an industrial boiler. The device includes: NO oxidation module 1 and selective catalytic reduction module 2. The NO oxidation module 1 includes a NO ion or ozone oxidation device 1.1 and a NO catalytic oxidation layer 1.2; the inside of the selective catalytic reduction module 2 is an inlet deflector 2.1 from top to bottom, an ammonia storage device and a nozzle connected to it. Ammonia device 2.2, catalytic reduction layers 2.3, 2.4, an outlet deflector 2.5 is installed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxidation efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com