Solvent-free phenolic epoxy electrostatic conductive coating formula and preparation method thereof

A phenolic epoxy conductive, solvent-free technology, applied in conductive coatings, epoxy resin coatings, anti-corrosion coatings, etc., can solve the problems of low cost performance, poor anti-corrosion performance, and no wear resistance of solvent-free epoxy electrostatic conductive coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention will be further described in detail below.

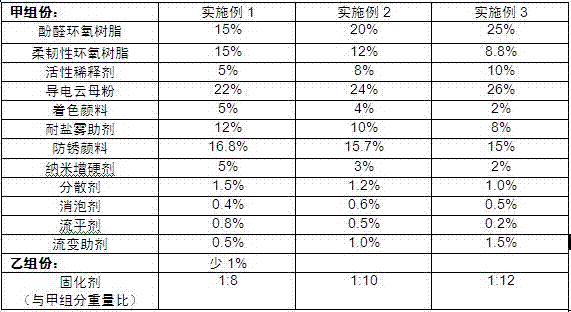

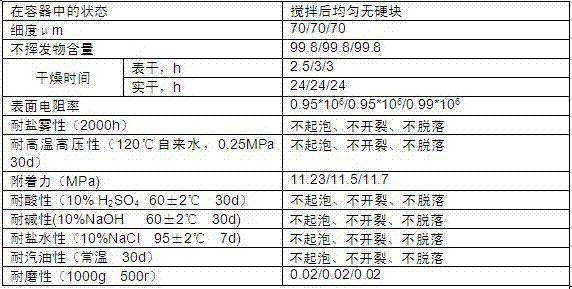

[0019] The formula of the solvent-free novolak epoxy electrostatic conductive coating of the present invention is composed of component A and component B in a weight ratio of 8-12:1, wherein component A consists of 15-25% of novolac epoxy resin; flexibility Epoxy resin 5-15%; reactive diluent 5-10%; conductive mica powder 15-25%; salt spray resistance additive 5-12%; pigment 12-20%; nano hardening agent 2-5%; dispersion 0.1-0.5% antifoaming agent; 0.3-0.8% leveling agent; 0.5-1.5% rheological additive; 0.5-2.0% silane coupling agent; all percentages are by weight; Parts are epoxy curing agent.

[0020] Novolac epoxy resin has high epoxy group content, high viscosity, high crosslinking density after curing, and its fiber-reinforced plastic has good physical and mechanical properties. Heat resistance is higher than E-type epoxy resin. It is mainly used to make various structural ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com