Saturated polyester resin and preparation method thereof, orange grain powder coating containing same and preparation method thereof

A polyester resin and plastic technology, applied in the fields of orange grain powder coating and preparation, saturated polyester resin and preparation, can solve the problems of outdoor weather resistance, water resistance, UV resistance, scratch resistance, and limited dosage and application. and other problems, to achieve the effect of wide range of use, good water resistance and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

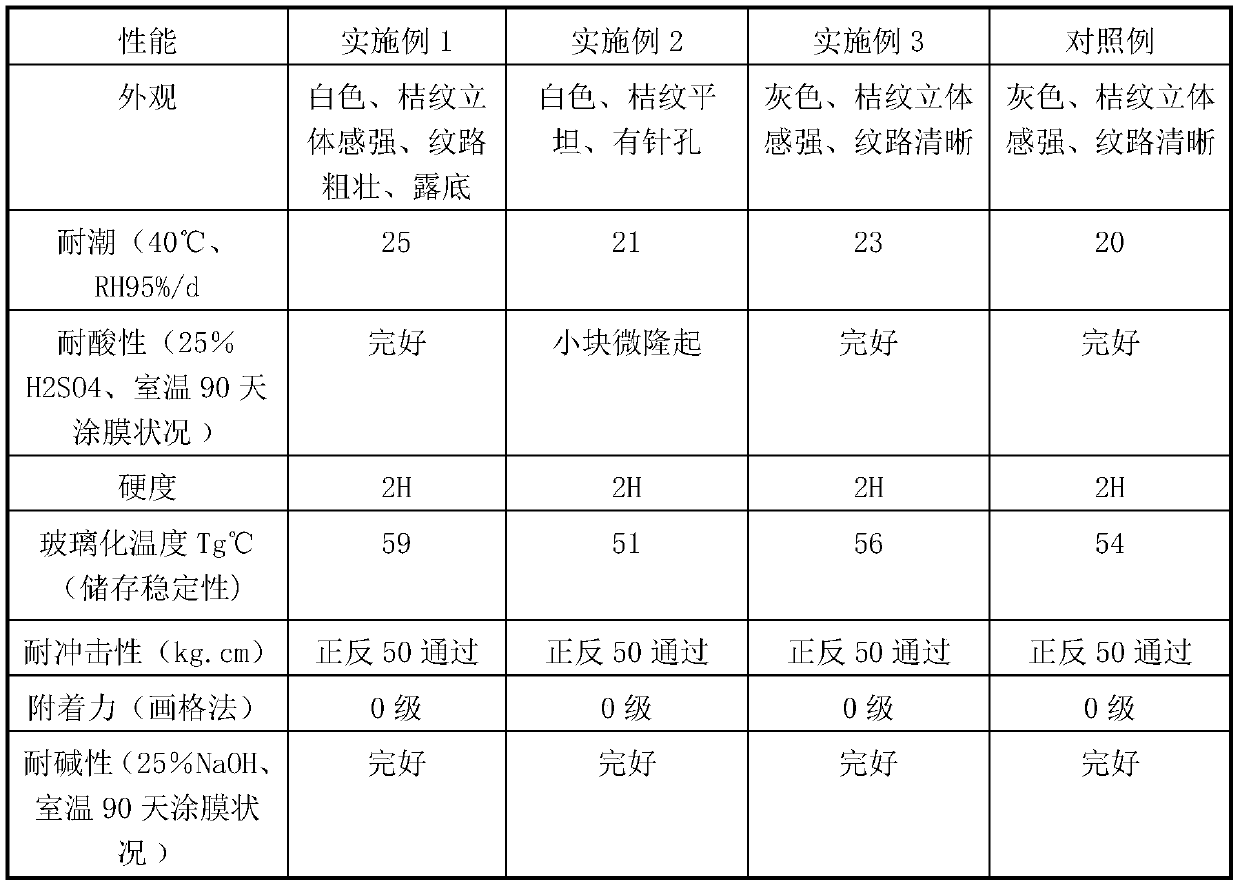

Examples

Embodiment 1

[0047]A preparation method for orange grain powder coating, comprising the following steps:

[0048] 1) Set the temperature of the far-infrared electric heating 2000L reactor equipped with stirring device, vertical condenser and horizontal condenser at 270°C, and start heating; put in 600kg of waste ethylene glycol residue crushed material, waste PEN plastic in turn Broken material 100kg, neopentyl glycol 150kg, diethylene glycol 50kg, ethylene glycol antimony 1.1kg; heat up to 160°C within two hours, start the stirring device at 20-30r / min, and control the top of the vertical condenser The temperature does not exceed 105°C, continue to heat up to 260-270°C for 3-5 hours, complete the transesterification chemical reaction and alcoholysis reaction until the plastic is melted and transparent; when the temperature drops to 180-190°C, add 100kg of trimellitic anhydride and 50kg of adipic acid , Monobutyltin oxide 0.5kg, AT168 antioxidant 3.5kg, AT10 antioxidant 1.5kg, then set the...

Embodiment 2

[0051] A preparation method for orange grain powder coating, comprising the following steps:

[0052] 1) Set the temperature of the far-infrared electric heating 2000L reactor equipped with stirring device, vertical condenser and horizontal condenser at 270°C, and start heating; put in 700kg of waste ethylene glycol residue crushed material, waste PEN plastic in turn Broken material 35kg, neopentyl glycol 50kg, diethylene glycol 100kg, ethylene glycol antimony 1kg; after two hours, heat up to 160°C, start the stirring device at 20-30r / min, and control the top of the vertical condenser The temperature does not exceed 105°C, continue to heat up to 260-270°C for 3-5 hours, complete the transesterification chemical reaction and alcoholysis reaction until the plastic is melted and transparent; when the temperature drops to 180-190°C, add 50 kg of trimellitic anhydride and 50 kg of adipic acid , 0.5kg of monobutyltin oxide, 3.5kg of AT168 antioxidant, 1.5kg of AT10 antioxidant, set ...

Embodiment 3

[0055] A preparation method for orange grain powder coating, comprising the following steps:

[0056] 1) Set the temperature of the far-infrared electric heating 2000L reactor equipped with stirring device, vertical condenser and horizontal condenser at 270°C, and start heating; put in 650kg of waste ethylene glycol residue crushed material, waste PEN plastic in turn Broken material 60kg, neopentyl glycol 50kg, diethylene glycol 150kg, zinc acetate 1.1kg; after two hours, heat up to 160°C, start the stirring device at 20-30r / min, and control the temperature at the top of the vertical condenser Do not exceed 105°C, continue to heat up to 260-270°C for 3-5 hours, complete the transesterification chemical reaction and alcoholysis reaction until the plastic is melted and transparent; when the temperature is lowered to 180°C-190, add 70 kg of trimellitic anhydride and 50 kg of adipic acid, mono Butyl tin oxide 0.5kg, AT168 antioxidant 3.5kg, AT10 antioxidant 1.5kg, set the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com