Part polishing equipment for hardware tool machining

A technology for parts and hardware, applied in the field of parts polishing equipment for hardware processing, can solve the problems of low polishing efficiency, cumbersome operation, uneven polishing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

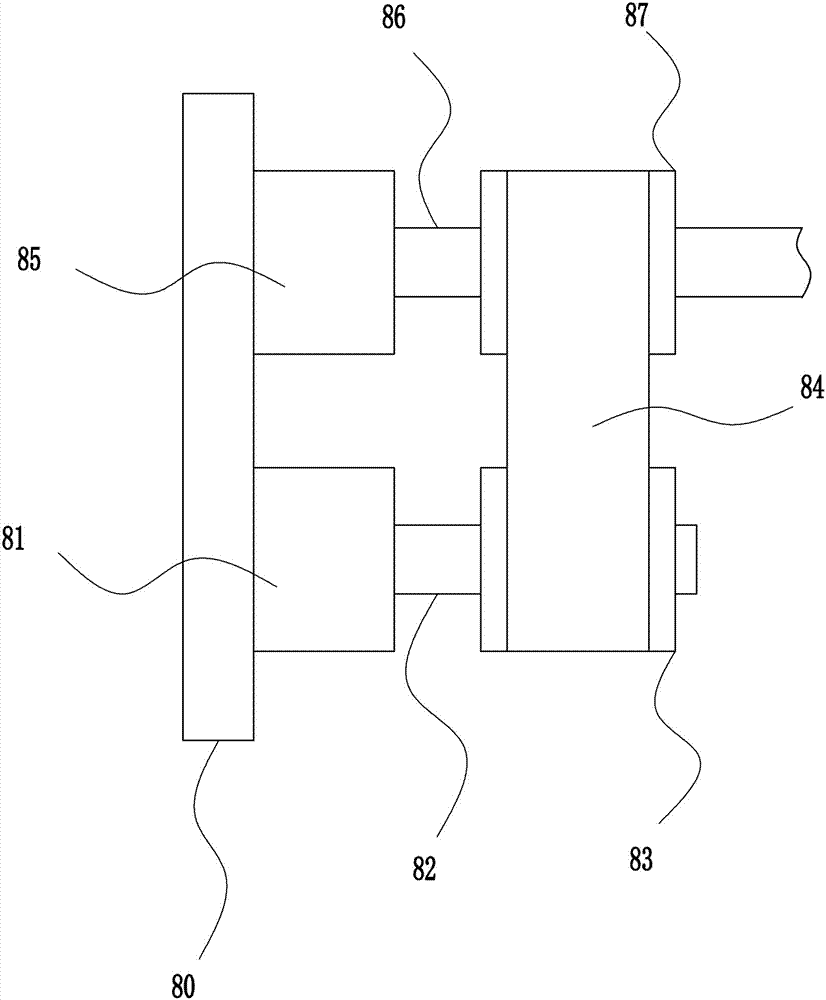

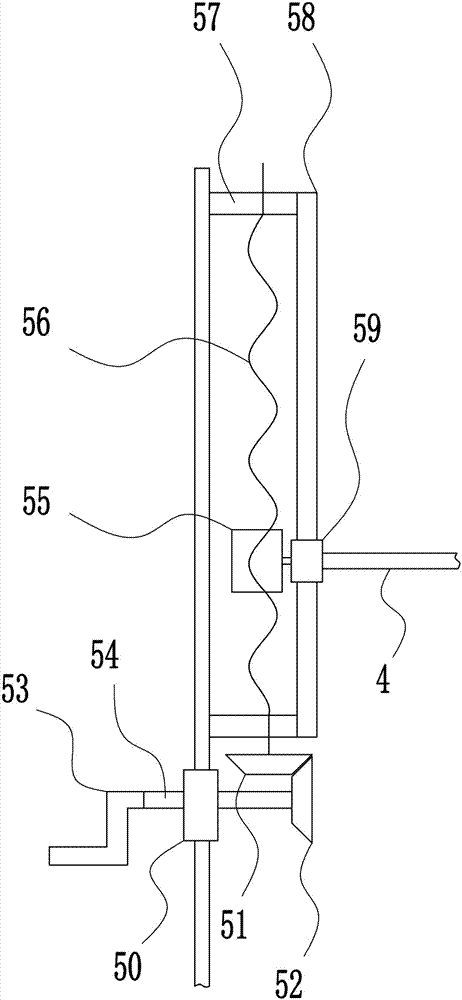

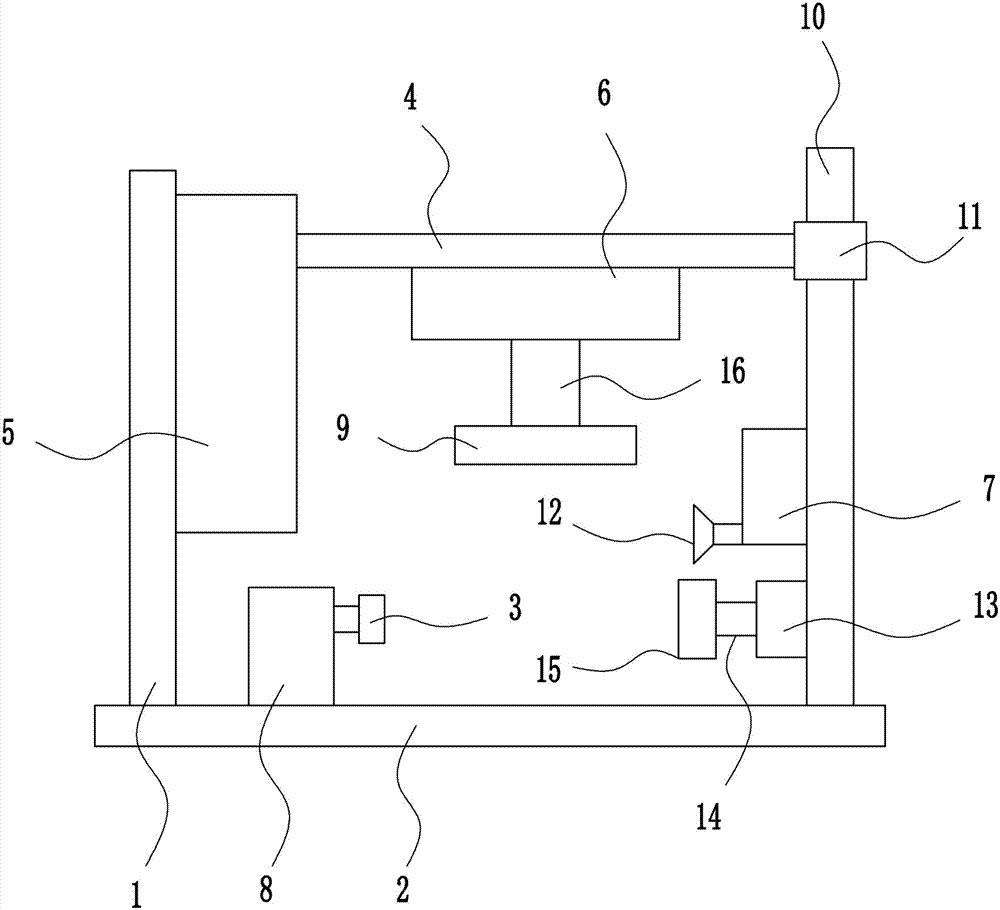

[0034] A kind of parts polishing equipment for metal processing, such as Figure 1-5 As shown, it includes a left frame 1, a base plate 2, a first fixed sleeve 3, a fixed plate 4, a lifting device 5, a first rotating device 6, an air spray device 7, a second rotating device 8, a polishing wheel 9, and a first guide post 10. The first guide sleeve 11, the nozzle 12, the first bearing seat 13, the first rotating shaft 14, the second fixed sleeve 15 and the second rotating shaft 16, the left frame 1 is welded on the left side of the top of the bottom plate 2, and the left frame 1 is set on the right side There is a lifting device 5, the right side of the lifting device 5 is welded with a fixed plate 4, the right side of the top of the base plate 2 is welded with a first guide post 10, the first guide post 10 is covered with a first guide sleeve 11, the right side of the fixed plate 4 is connected to the second A guide sleeve 11 is connected on the left side, a second rotating dev...

Embodiment 2

[0036] A kind of parts polishing equipment for metal processing, such as Figure 1-5 As shown, it includes a left frame 1, a base plate 2, a first fixed sleeve 3, a fixed plate 4, a lifting device 5, a first rotating device 6, an air spray device 7, a second rotating device 8, a polishing wheel 9, and a first guide post 10. The first guide sleeve 11, the nozzle 12, the first bearing seat 13, the first rotating shaft 14, the second fixed sleeve 15 and the second rotating shaft 16, the left frame 1 is welded on the left side of the top of the bottom plate 2, and the left frame 1 is set on the right side There is a lifting device 5, the right side of the lifting device 5 is welded with a fixed plate 4, the right side of the top of the base plate 2 is welded with a first guide post 10, the first guide post 10 is covered with a first guide sleeve 11, the right side of the fixed plate 4 is connected to the second A guide sleeve 11 is connected on the left side, a second rotating dev...

Embodiment 3

[0039] A kind of parts polishing equipment for metal processing, such as Figure 1-5 As shown, it includes a left frame 1, a base plate 2, a first fixed sleeve 3, a fixed plate 4, a lifting device 5, a first rotating device 6, an air spray device 7, a second rotating device 8, a polishing wheel 9, and a first guide post 10. The first guide sleeve 11, the nozzle 12, the first bearing seat 13, the first rotating shaft 14, the second fixed sleeve 15 and the second rotating shaft 16, the left frame 1 is welded on the left side of the top of the bottom plate 2, and the left frame 1 is set on the right side There is a lifting device 5, the right side of the lifting device 5 is welded with a fixed plate 4, the right side of the top of the base plate 2 is welded with a first guide post 10, the first guide post 10 is covered with a first guide sleeve 11, the right side of the fixed plate 4 is connected to the second A guide sleeve 11 is connected on the left side, a second rotating dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com