A kind of preparation method of continuous fiber reinforced nylon 6 composite material

A composite material and continuous fiber technology, which is applied in the preparation of continuous fiber reinforced nylon 6 composite materials and the field of continuous fiber reinforced nylon 6 composite materials prepared by resin transfer molding. Problems such as mechanical properties of materials, to achieve the effect of improving mechanical properties, good impregnation, and excellent pressure-holding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

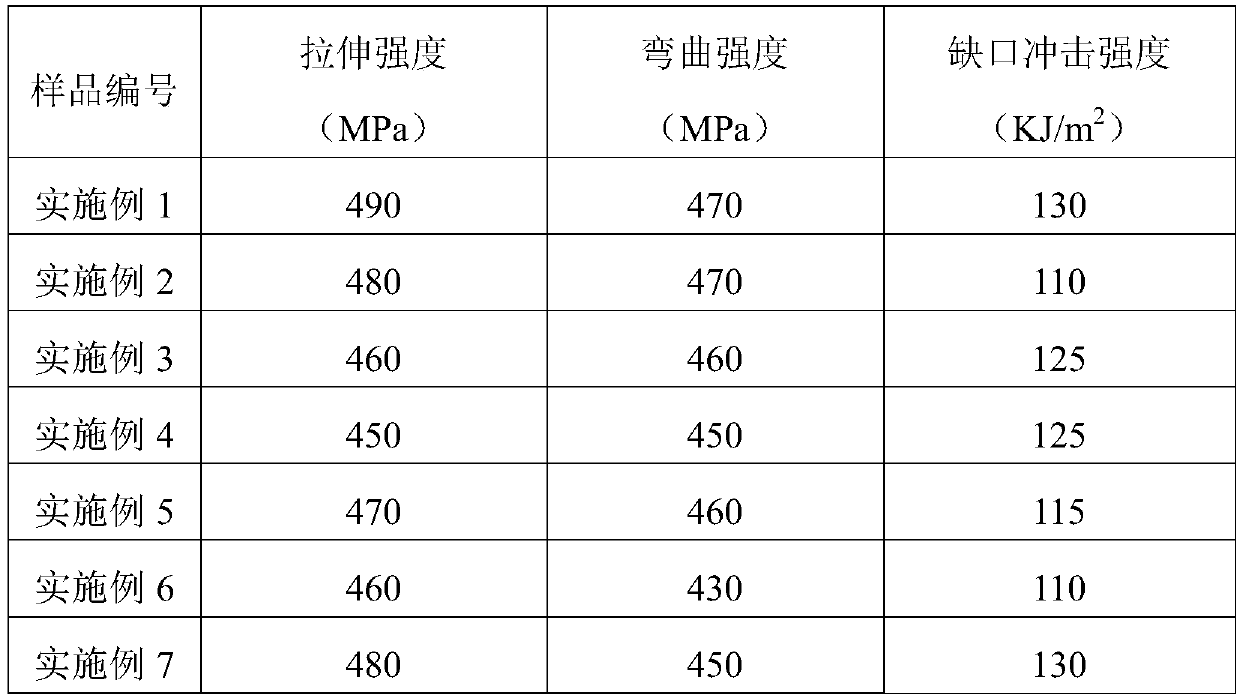

Examples

Embodiment 1

[0024] A preparation method for preparing continuous fiber-reinforced nylon 6 composite material, which is prepared as follows:

[0025] Weigh 600g of caprolactam and heat it to 70°C to melt, remove a small amount of water through vacuum distillation, then divide the molten mixture into two parts of equal weight, and add them to liquid feeding devices A and B respectively. After adding 0.024g of sodium to tank A, distill off a small amount of water in it under reduced pressure; add 0.024g of toluene-2,4-diisocyanate into tank B and fully dissolve it; according to the shape of the mold, cut the 400g Spread the carbon fiber cloth into the mold neatly, close the mold, and preheat the temperature to 70°C; turn on the preheated injection molding machine, and set the temperature of the injection machine from the feed port to the nozzle to 70, 90, 100, and 120°C in sequence, and turn on Liquid feeding devices A and B, at the same rate, feed the caprolactam melt into the feeding port ...

Embodiment 2

[0027] A preparation method for preparing continuous fiber-reinforced nylon 6 composite material, which is prepared as follows:

[0028]Weigh 200g of caprolactam and heat it to 120°C to melt, remove a small amount of water through vacuum distillation, then divide the molten mixture into two parts of equal weight, and add them to liquid feeding devices A and B respectively. After adding 0.2g sodium hydroxide to tank A, distill under reduced pressure to remove a small amount of water therein; add 0.2g maleic anhydride to tank B and fully dissolve it; according to the shape of the mould, cut a hemp fiber cloth with a mass of 800g , neatly spread into the mold, close the mold, preheat the temperature to 120°C; turn on the preheated injection molding machine, set the temperature from the feeding port to the nozzle of the injection machine to 70, 90, 100, 120°C in sequence, and start the liquid feeding Devices A and B, at the same rate, add the caprolactam melt into the feeding port...

Embodiment 3

[0030] A preparation method for preparing continuous fiber-reinforced nylon 6 composite material, which is prepared as follows:

[0031] Weigh 400g of caprolactam and heat it to 95°C to melt, remove a small amount of water through vacuum distillation, then divide the molten mixture into two parts of equal weight, and add them to liquid feeding devices A and B respectively. After adding 2.008g of sodium hydride to tank A, distill under reduced pressure to remove a small amount of water; add 2.008g of diphenylmethane diisocyanate into tank B and dissolve it fully; according to the shape of the mould, cut glass fibers with a mass of 600g Lay the cloth neatly into the mold, close the mold, and preheat the temperature to 95°C; turn on the preheated injection molding machine, set the temperature from the feed port to the nozzle of the injection machine at 70, 90, 100, and 100°C in sequence, and turn on the liquid Feeding devices A and B, at the same rate, feed the caprolactam melt i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com