Lowering device of impregnation tank workpiece basket

An impregnation tank and workpiece basket technology, which is applied in the field of lowering device of the impregnation tank workpiece basket, can solve problems such as loss of effect, reduction of impregnation pass rate, discount of impregnation effect, etc., so as to realize automation and improve impregnation pass rate , Guarantee the effect of impregnation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

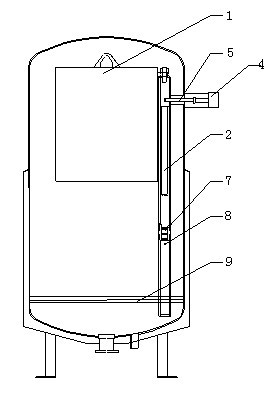

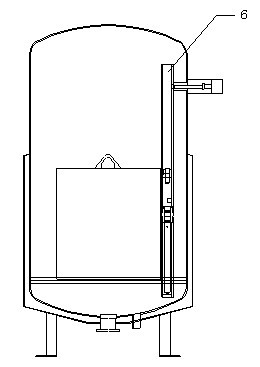

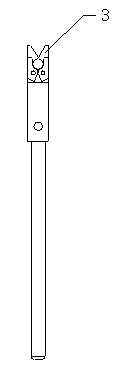

[0014] A lowering device for the workpiece basket of an infiltration tank according to the present invention comprises a guide sleeve 6, a slide rod 2, a cylinder 4, and a movable pin 5, wherein the cylinder 4 is connected with the movable pin 5, and the expansion and contraction of the cylinder 4 drives the expansion and contraction of the movable pin 5, and the guide sleeve A slide bar 2 is set in 6, a hole is opened on the side of the guide sleeve 2 close to the movable pin 5, a groove is opened on the side of the slide bar close to the movable pin 5, and a workpiece basket slot with a Hafur structure slot 3 is provided on the top of the slide bar 2 , the Hafur structure card slot 3 is set in the middle of the two fixed card slots 10, the lower end of the guide sleeve 6 has a liquid outlet hole 8, and the guide sleeve 6 at the upper end of the liquid outlet hole 8 is provided with a sealing sleeve 7, and the guide sleeve 6 and The inner wall of the infiltration tank is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com