Network structure design-based wide-temperature range polyurethane elastomer damping material and method and application thereof

A polyurethane elastomer and damping material technology, applied in the field of damping materials, can solve the problems of damage to the mechanical properties of polymer materials, inability to meet actual use requirements, poor damping effect, etc., and achieve improved compatibility, good damping performance, and conformation. changeable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A method for preparing a wide temperature range polyurethane elastomer damping material based on network structure design, comprising the following steps:

[0055] (1) Under the condition of stirring (200r / min), 20 parts by weight of polyester diol are subjected to vacuum drying treatment (the condition of vacuum drying treatment is to dry at 100°C for 2.5h under 1MPa pressure) to obtain pretreated of polyester diol;

[0056] (2) the polyester diol of pretreatment in step (1) is cooled to room temperature, closes vacuum pump, logical N 2 , stirring at a medium speed (250r / min), adding 3 parts by weight of TDI, heating up to 80°C, adding dropwise 0.003 parts by weight of dibutyltin dilaurate as a catalyst, keeping the temperature for 1.5h, stopping the reaction, and obtaining an elastic main chain prepolymer that is Polyurethane prepolymer, N 2 Save under atmosphere;

[0057] (3) in N 2 Under the protection of atmosphere, add 3 parts by weight of TDI to 10 parts by w...

Embodiment 2

[0060] A method for preparing a wide temperature range polyurethane elastomer damping material based on network structure design, comprising the following steps:

[0061] (1) Under the condition of stirring (200r / min), 30 parts by weight of polyester diol are subjected to vacuum drying treatment (the condition of vacuum drying treatment is to dry at 100°C for 2.5h under 1MPa pressure), to obtain pretreated of polyester diol;

[0062] (2) the polyester diol of pretreatment in step (1) is down to room temperature, closes vacuum pump, logical N 2 , N 2 Add 7 parts by weight of TDI under the protection of the atmosphere, stir at a medium speed (250r / min), heat up to 80°C, add 0.004 parts by weight of the catalyst dibutyltin dilaurate dropwise, keep the temperature for 1.5h, stop the reaction, and obtain the elastic main chain prepolymerization The material is polyurethane prepolymer, N 2 Save under atmosphere;

[0063] (3) in N 2 Under the protection of atmosphere, add 5 part...

Embodiment 3

[0066] A method for preparing a wide temperature range polyurethane elastomer damping material based on network structure design, comprising the following steps:

[0067] (1) Under the condition of stirring (200r / min), 15 parts by weight of polyester diol are vacuum-dried (the condition of vacuum-dried treatment is to dry at 100°C for 2.5h under 1MPa pressure) to obtain pre-treated of polyester diol;

[0068] (2) the polyester diol of pretreatment in step (1) is down to room temperature, closes vacuum pump, logical N 2 , add 3 parts by weight of TDI, stir at medium speed (250r / min), heat up to 80°C within a few minutes, add 0.0015 parts by weight of catalyst dibutyltin dilaurate dropwise, keep warm for 1.5h, stop the reaction, and obtain the elastic main chain Prepolymer is polyurethane prepolymer, N 2 Save under atmosphere;

[0069] (3) in N 2 Under the protection of atmosphere, add 3 parts by weight of TDI to 5 parts by weight of polyethylene glycol monomethyl ether (mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

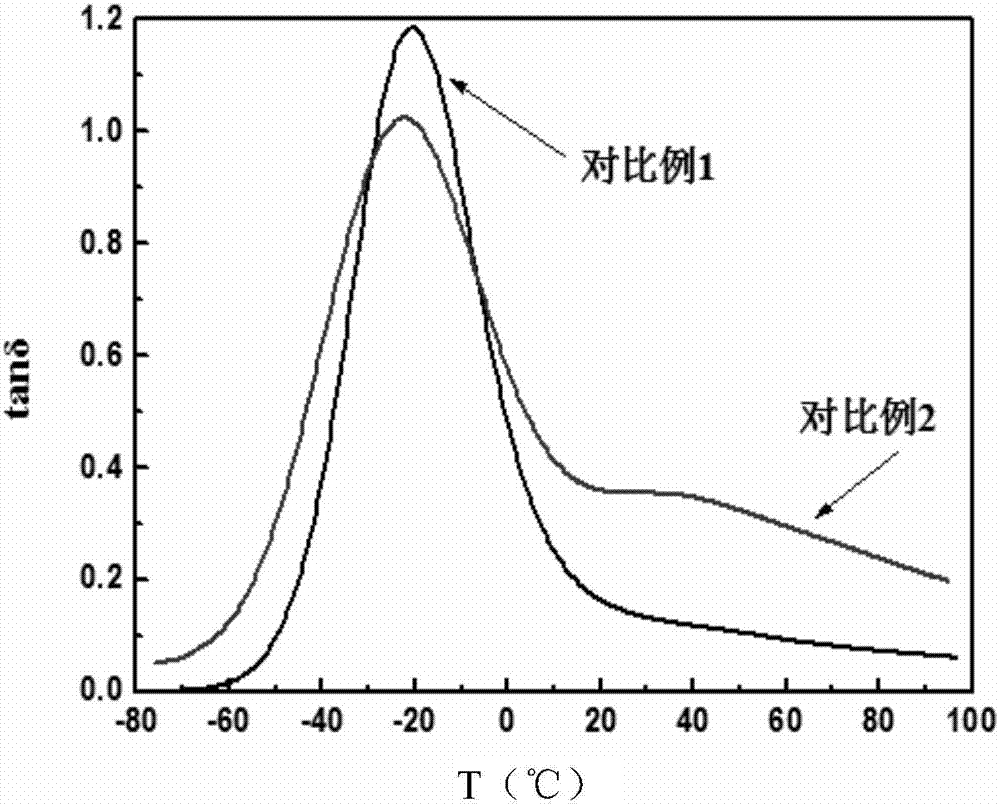

| Damping factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com