Method for wrapping silicon dioxide particle surface with aluminum oxide

A technology of aluminum oxide and silicon dioxide, which is applied in the field of composite materials, can solve the problems of difficult phase formation and uneven contact of silicon dioxide, and achieve the goal of being suitable for large-scale industrial production, improving the contact area, and reducing the difficulty of phase formation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

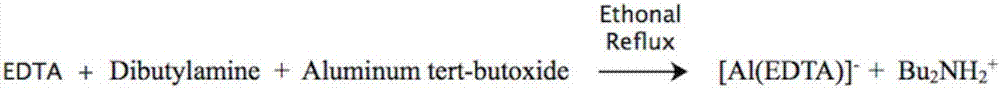

[0026] Dissolve 2.21g of ethylenediaminetetraacetic acid in 20g of absolute ethanol, heat on a heating stirrer and keep the temperature at 100°C, add 1.18g of dibutylamine dropwise under stirring and keep stirring for 4 hours, keeping the above temperature , add 1.87g of tert-butoxyaluminum and continue to stir for 4 hours, after fully reacting, an aluminum-containing organic ion solution is obtained. Add silicon dioxide powder with a particle size of 50 μm into the aluminum-containing organic ion solution, stir at 100°C until it volatilizes and dries to form a honey-like gel, transfer the gel to a crucible and heat it in a muffle furnace at 600°C Calcined at high temperature for 5 hours to obtain silicon dioxide powder coated with aluminum oxide.

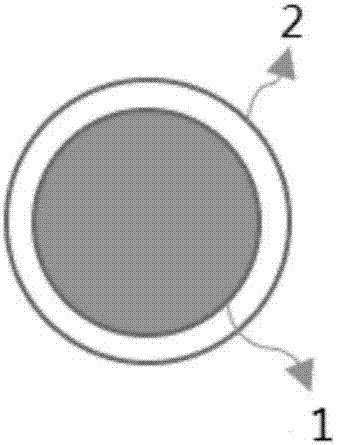

[0027] The structure of the prepared silica powder coated with Al2O3 is as follows: figure 1 As shown, wherein the aluminum oxide coating layer 2 is coated on the surface of the silica particles 1, and the thickness of the aluminu...

Embodiment 2

[0029] Dissolve 4.42g of ethylenediaminetetraacetic acid in 20g of absolute ethanol, heat on a heating stirrer and keep the temperature at 100°C, add 2.36g of dibutylamine dropwise under stirring and keep stirring for 4 hours, keeping the above temperature , add 3.74g of tert-butoxyaluminum and continue to stir for 4 hours, after fully reacting, an aluminum-containing organic ion solution is obtained. Add silicon dioxide powder with a particle size of 50 μm into the aluminum-containing organic ion solution, stir at 100°C until it volatilizes and dries to form a honey-like gel, transfer the gel to a crucible and heat it in a muffle furnace at 600°C Calcined at high temperature for 5 hours to obtain silicon dioxide powder coated with aluminum oxide.

[0030] The structure of the prepared silica powder coated with Al2O3 is as follows: figure 1 As shown, wherein the aluminum oxide coating layer 2 is coated on the surface of the silica particle 1, and the thickness of the aluminum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com