Oil cooling electric driving force rotor structure

A technology of rotor structure and driving force, applied in the field of electric motors, can solve the problems of high temperature demagnetization, high fuel consumption, limited power density, etc., and achieve the effect of high oil usage rate, low consumption and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

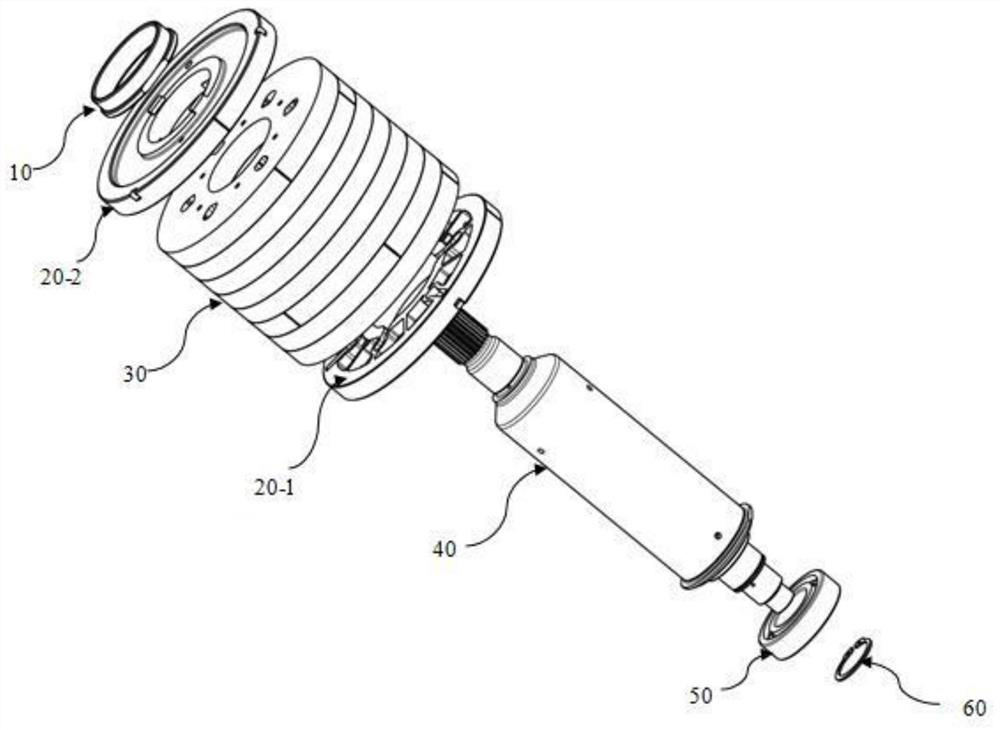

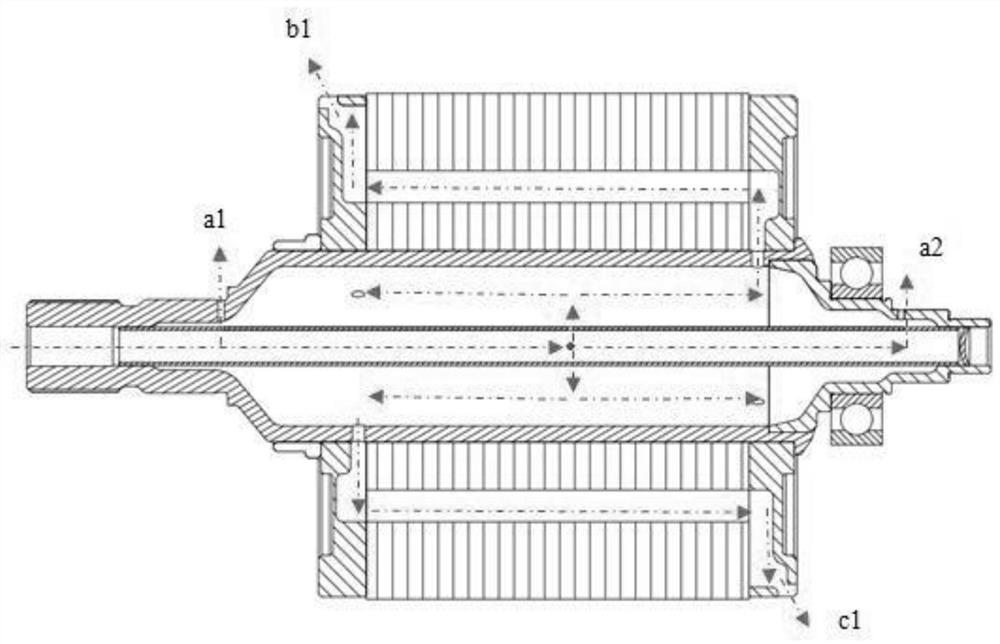

[0025] Such as figure 1 In the illustrated embodiment, an oil-cooled electric drive rotor structure includes a motor shaft 40 and a rotor core assembly mounted on the motor shaft. The motor shaft includes a main shaft body 41, an inner insertion tube 42, a shaft head 43 and stuffy 44, such as Figure 3 to Figure 5 As shown, the main shaft body is made of formed steel pipe raw material, which is processed by rotary forging, and the shaft head is forged into a blank for forming. Two oil holes 49, the main shaft body and the shaft head are press-fitted with a circular seam interference fit, and then the end is riveted by a pressure riveting process to prevent the shaft head from coming out; the inner tube is made of aluminum pipe, and the inner tube Press-fitted in the cavity, the side of the inner insertion tube is provided with a main oil outlet 47, a first oil outlet and a second oil outlet, and the first oil outlet and the second oil outlet are connected with the first oil h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com