Method of preparing pipe by double-melting-point composite film

A composite film and double melting point technology, which is applied in applications, household appliances, tubular objects, etc., can solve the problems of low cost and increased production cost, and achieve the effect of improving breaking strength and sealing degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

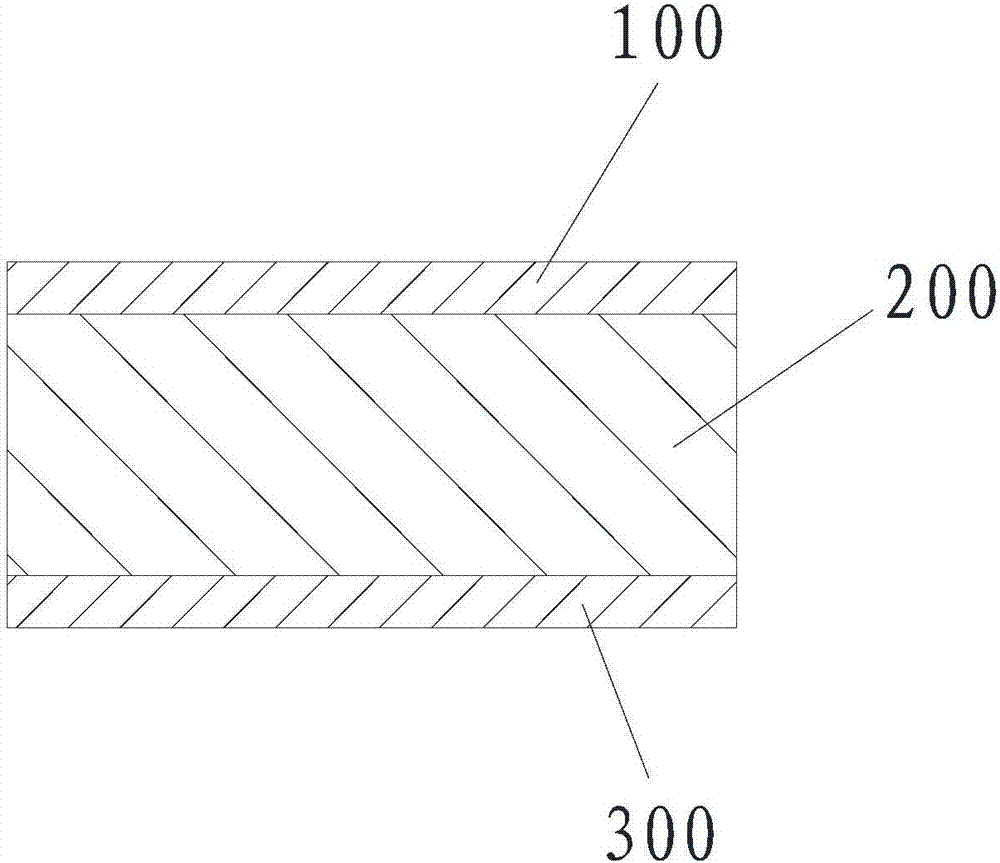

[0019] In the method for preparing pipes using a double-melting point composite film of the present invention, the used double-melting point composite film is as follows: figure 1 As shown, it includes an upper surface layer 100, an interlayer 200 and a lower surface layer 300 that are combined together. The upper surface layer 100 and the lower surface layer 300 are both PE layers, and the interlayer 300 has a melting point of 240-260°C. The high melting point PET layer. The upper surface layer 100, the interlayer 200 and the lower surface layer 300 can be composited together by conventional extrusion biaxial stretching process.

[0020] As a preferred option, the thickness ratio of the upper surface layer 100, the interlayer 200 and the lower surface layer 300 is 5-20:60-90:5-20.

[0021] As a preferred option, the total thickness of the composite membrane of the present invention is 5-100 filaments.

[0022] As a preferred option, the width of the composite film of the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com