Positive electrode material Fe<x>Co<1-x>S<2> powder of thermal battery and preparation method for powder

A kind of positive electrode material, 0 prone to thermal decomposition reaction, expensive, capacitance drop and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

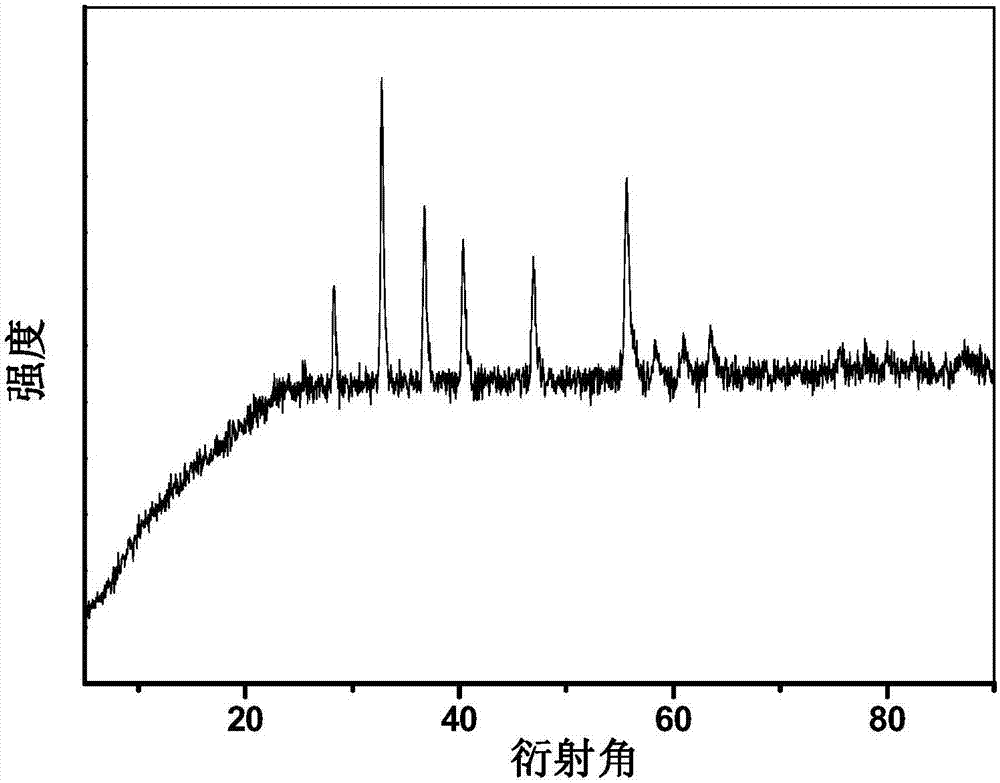

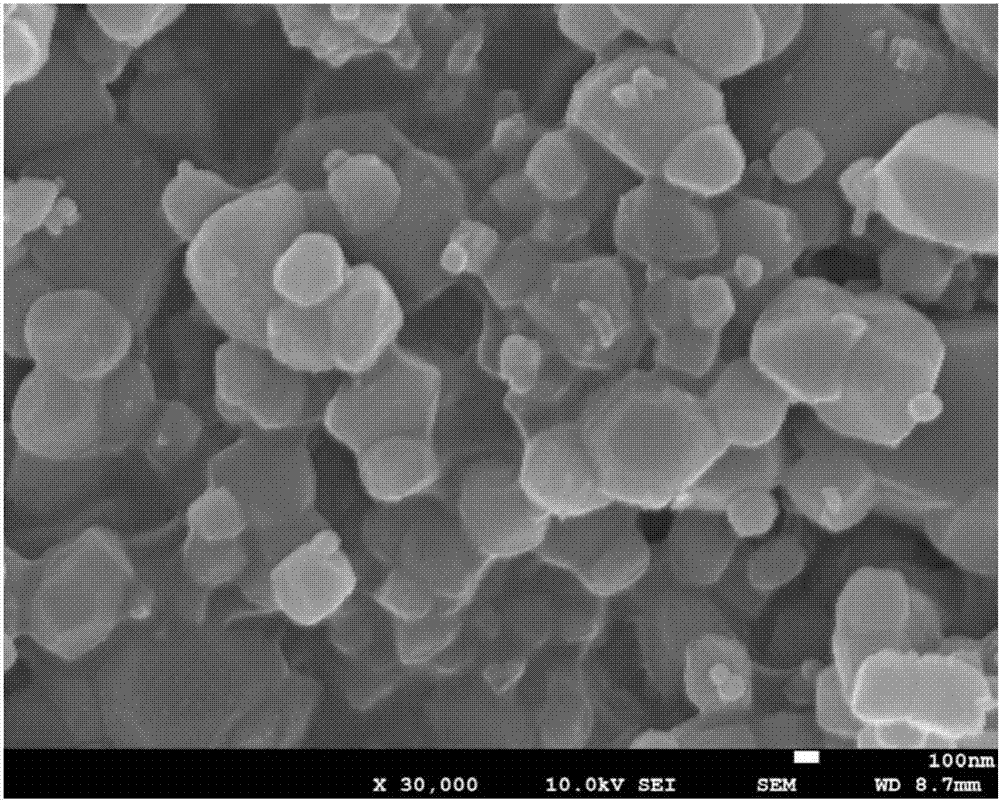

[0058] The specific embodiment part of the present invention provides thermal battery anode material Fe x co 1-x S 2 Powder and preparation method thereof, described method such as figure 1 shown, including the following steps:

[0059] (1) raw material iron source and cobalt source are mixed in proportion and made mixed solution;

[0060] (2) Add a precipitating agent to the mixed solution prepared in step (1) and fully stir to carry out a precipitation reaction, and the precipitate obtained in the reaction is washed and filtered to obtain a precipitate;

[0061] (3) The precipitate obtained in step (2) is vacuum-dried to obtain a homogeneously mixed Fe x co 1-x S dry powder;

[0062] (4) Fe in step (3) x co 1-x S dry powder is mixed with excess S powder, and under a protective atmosphere, a compound reaction is carried out to obtain S-containing Fe x co 1-x S 2 Powder;

[0063] (5) Fe containing S obtained in step (4) x co 1-x S 2 The powder is desulfurized un...

Embodiment 1

[0066] This example provides Fe 0.5 co 0.5 S 2 The preparation method of powder, described method comprises the following steps:

[0067] (1) Weigh 139g FeSO 4 ·7H 2 O and 140.5 g CoSO 4 ·7H 2 O is used as the initial raw material, and the two are dissolved in the medium at room temperature at the same time and stirred to make it completely dissolved;

[0068] (2) slowly add 288g precipitating agent Na in the mixed solution that step (1) makes 2 S·9H 2 O, fully stirred at a rate of 130rad / min for 6h during this period to obtain black precipitate Fe 0.5 co 0.5 S, and the precipitate is washed and filtered, and the Ba 2+ After the aqueous solution, no white precipitate is produced, and the precipitate is obtained;

[0069] (3) The precipitate obtained in step (2) was vacuum-dried at 120°C for 21 hours to obtain a homogeneously mixed Fe 0.5 co 0.5 S dry powder;

[0070] (4) Fe in step (3) 0.5 co0.5 S dry powder and 64g sublimated S powder were mixed and placed in a...

Embodiment 2

[0075] This example provides Fe 0.7 co 0.3 S 2 The preparation method of powder, described method comprises the following steps:

[0076] (1) Weigh 194.6g FeSO 4 ·7H 2 O and 84.3 g CoSO 4 ·7H 2 O is used as the initial raw material, and the two are dissolved in the medium at room temperature at the same time and stirred to make it completely dissolved;

[0077] (2) slowly add 288g precipitating agent Na in the mixed solution that step (1) makes 2 S·9H 2 O, fully stirred at a rate of 100rad / min for 10h during this period to obtain a black precipitate Fe 0.7 co 0.3 S, and the precipitate is washed and filtered, and the Ba 2+ After the aqueous solution, no white precipitate is produced, and the precipitate is obtained;

[0078] (3) The precipitate obtained in step (2) was vacuum-dried at 120°C for 20 hours to obtain a homogeneously mixed Fe 0.7 co 0.3 S dry powder;

[0079] (4) Fe in step (3) 0.7 co 0.3 S dry powder and 64g sublimated S powder were mixed and place...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com