A kind of superhydrophobic superoleophilic melamine foam and its preparation method and application

A technology of lipophilic melamine and melamine, which is applied in chemical instruments and methods, other chemical processes, alkali metal compounds, etc., can solve the problems that melamine materials have not reached the superhydrophobic state, the modification takes a long time, and is unfavorable for large-scale production. Accurate and efficient modification method, good reusability, and improved oil-water selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

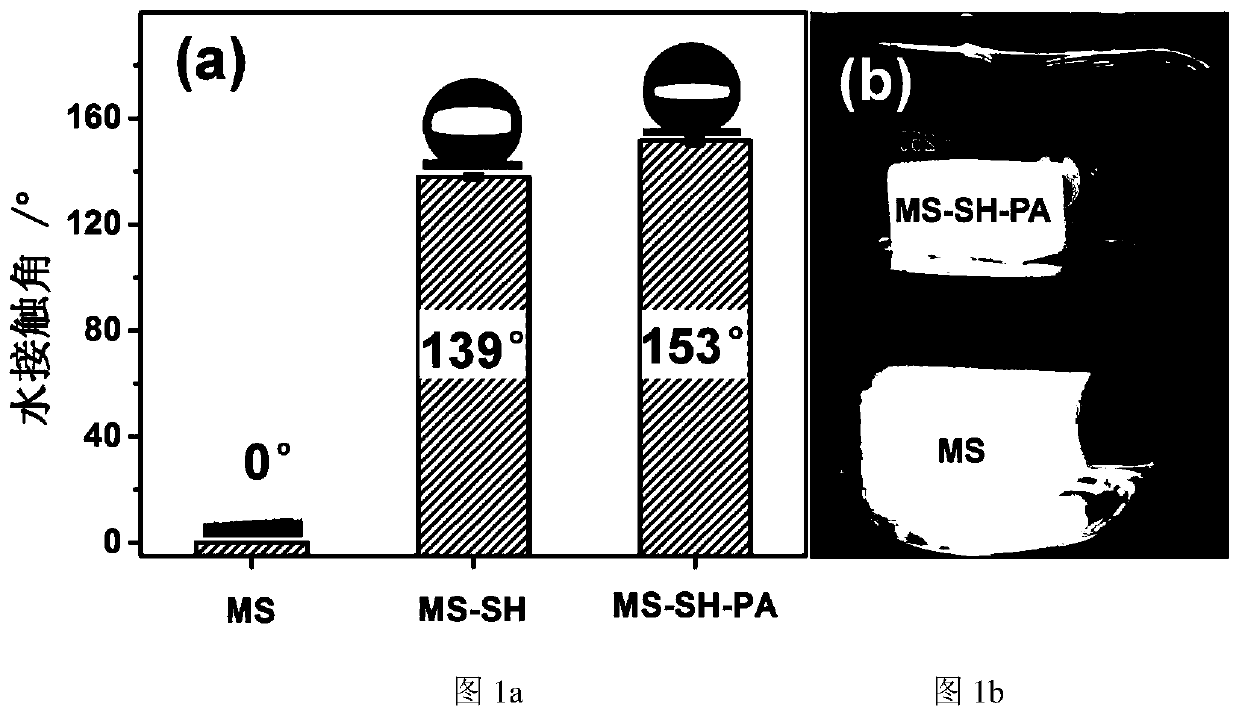

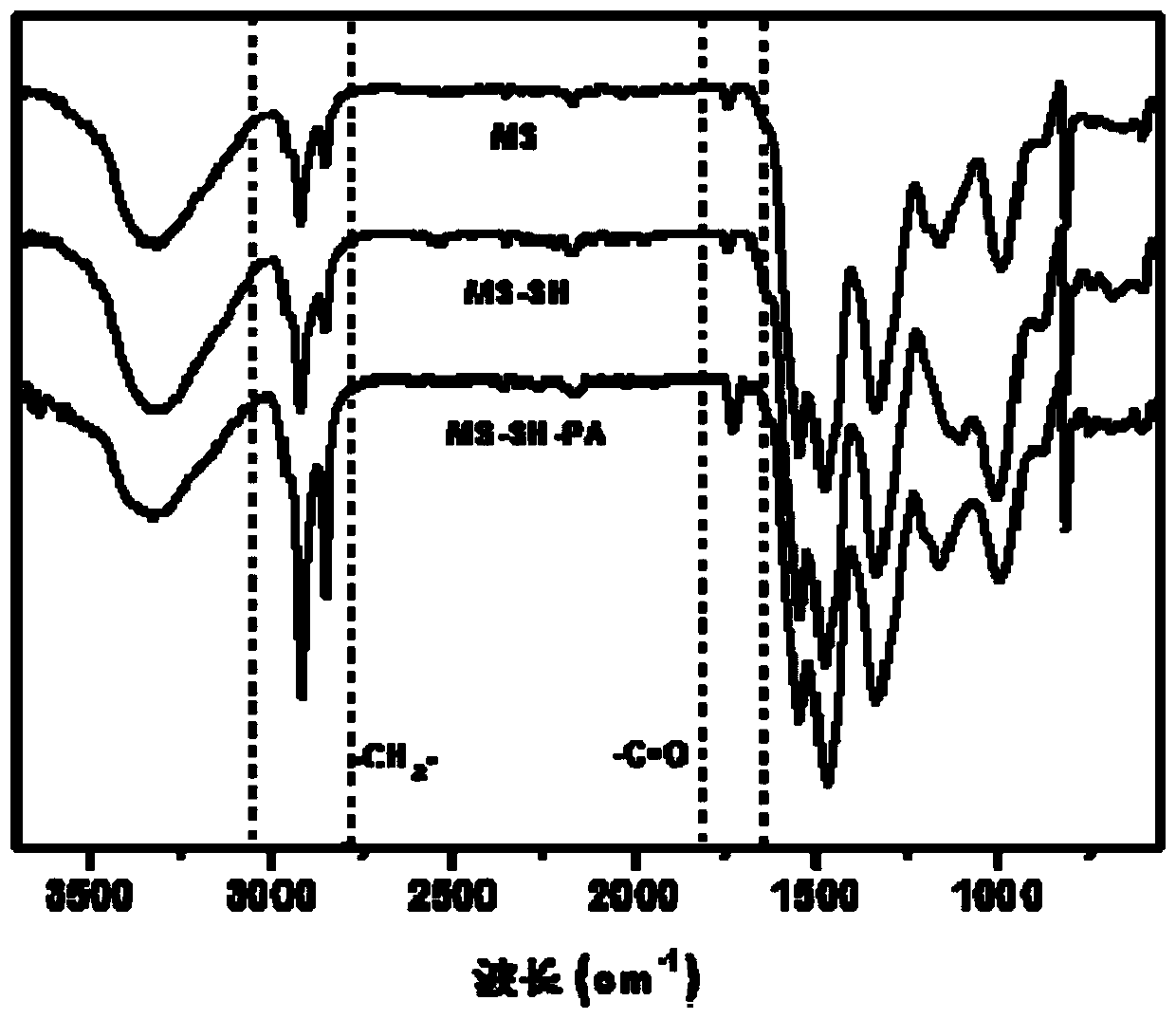

[0038]Mix 3‐mercaptopropyltriethoxysilane, deionized water, and absolute ethanol in a volume ratio of 2:3:45, adjust the pH of the system to 4 with 0.1mol / L hydrochloric acid, and stir for 1 hour at room temperature to prepare Obtain pre-hydrolyzate;

[0039] Immerse the melamine foam (MS) under the surface of the above-mentioned prehydrolyzed liquid, take it out after reacting for 2 hours, clean it with ethanol, and dry it at 80°C to prepare the mercaptolated melamine foam (MS-SH);

[0040] Mix photoinitiator 1173, octadecyl methacrylate, and tetrahydrofuran in a quartz container to obtain a mixed solution, wherein the concentration of octadecyl methacrylate is 0.1mmol / L, and the amount of photoinitiator 1173 accounts for 1% of methacrylic acid 10% of octadecyl ester mass. The resulting mercaptolated melamine foam (MS-SH) was immersed below the liquid surface of the mixed solution, placed at 3 cm above the liquid surface with a 40W ultraviolet lamp, and energized for 1 hour ...

Embodiment 2

[0048] Mix 3‐mercaptopropyltriethoxysilane, deionized water, and absolute ethanol uniformly in a volume ratio of 1.5:4:45, adjust the pH of the system to 4 with 0.1mol / L hydrochloric acid, and stir for 1.5 hours at room temperature to prepare Obtain pre-hydrolyzate;

[0049] Immerse the melamine foam (MS) under the surface of the above-mentioned prehydrolyzed liquid, take it out after reacting for 2.5 hours, clean it with ethanol, and dry it at 80°C to prepare the mercaptolated melamine foam (MS‐SH);

[0050] Mix photoinitiator 184, octadecyl methacrylate, and tetrahydrofuran in a quartz container to prepare a mixed solution, wherein the concentration of octadecyl methacrylate is 0.1mmol / L, and the amount of photoinitiator 184 accounts for 1% of methacrylic acid 10% of octadecyl ester mass. Immerse the obtained MS‐SH under the liquid surface of the mixed solution, place a 40W ultraviolet lamp at 3 cm above the liquid surface, and irradiate with electricity for 1 hour to prepa...

Embodiment 3

[0054] Mix 3‐mercaptopropyltrimethoxysilane, deionized water, and absolute ethanol uniformly in a volume ratio of 2.5:4:45, adjust the pH of the system to 4 with 0.1mol / L hydrochloric acid, and stir for 2 hours at room temperature to obtain pre-hydrolyzate;

[0055] Immerse the melamine foam (MS) under the surface of the above-mentioned pre-hydrolyzed liquid, take it out after reacting for 3 hours, clean it with ethanol, and dry it at 80°C to prepare the mercaptolated melamine foam (MS-SH);

[0056] Mix photoinitiator 1173, hexadecyl methacrylate, and tetrahydrofuran in a quartz container to prepare a mixed solution, wherein the concentration of stearyl methacrylate is 0.15mmol / L, and the amount of photoinitiator 1173 accounts for 1% of methacrylic acid 10% of octadecyl ester mass. Immerse the MS-SH obtained in step 2 below the liquid surface of the mixed solution, place a 40W ultraviolet lamp at 3 cm above the liquid surface, and irradiate with electricity for 1 hour to prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com