Automatic cutting control system and automatic cutting control method for coal cutter

A control system and shearer technology, applied in earthwork drilling, cutting machinery, etc., can solve the problems of large safety hazards, low degree of mechanization, and low output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

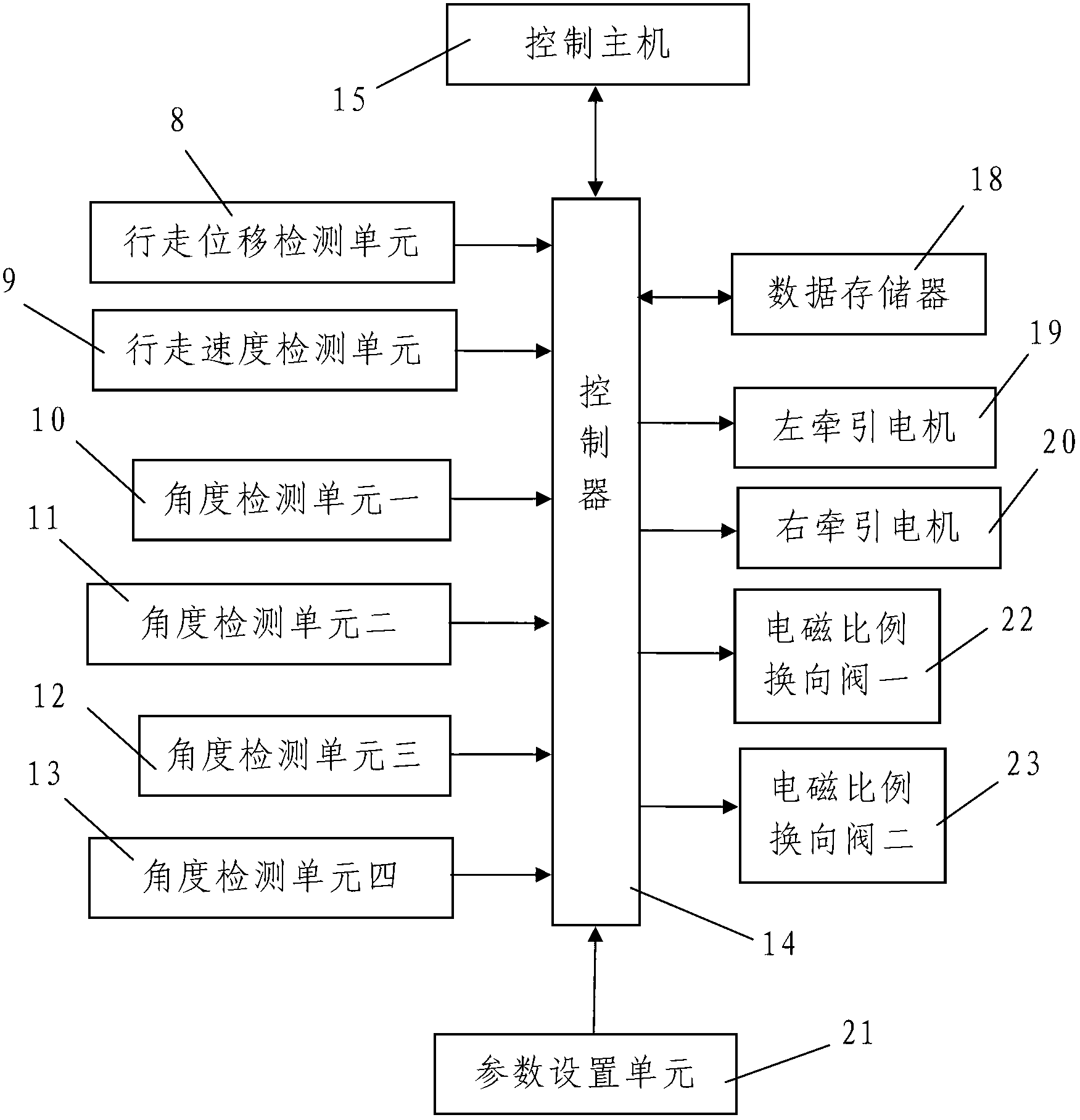

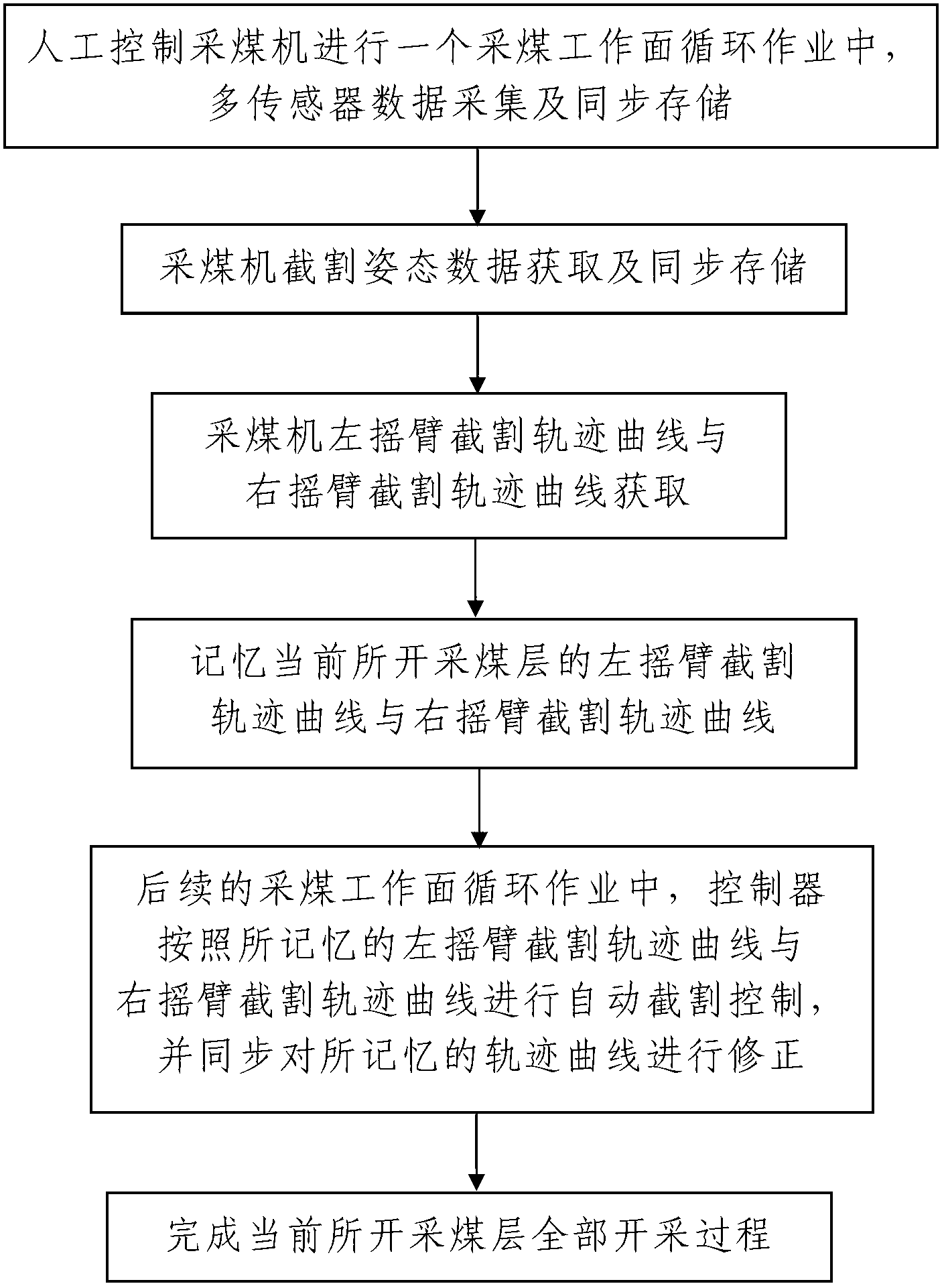

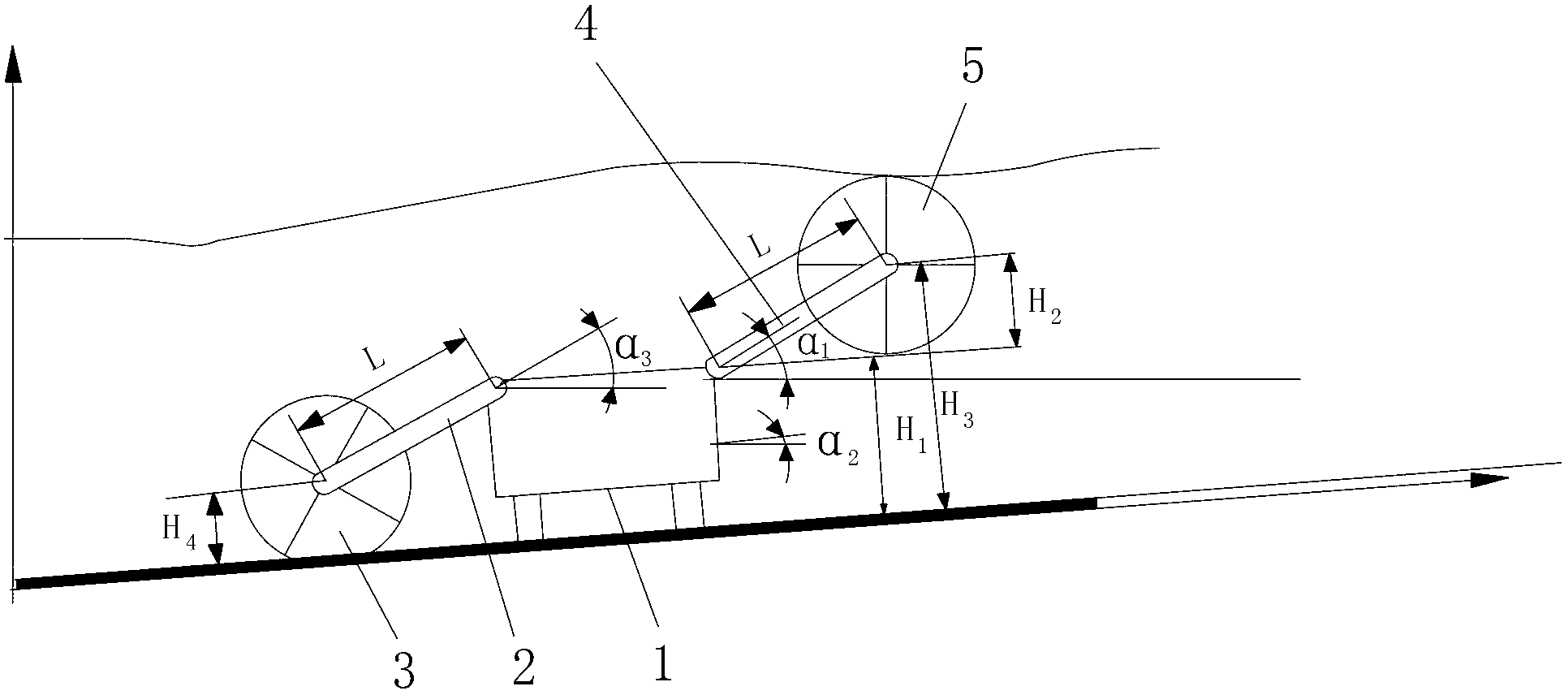

[0052] Such as figure 1 An automatic cutting control system for a shearer is shown, the controlled shearer is a double-drum shearer, and the left cutting part of the double-drum shearer includes a The left rocker arm 2 on the body 1, the left roller 3 installed at the front end of the left rocker arm 2, and the left cutting motor driving the left roller 3, the left roller 3 is in transmission connection with the left cutting motor, and The right cutting part of the double-drum shearer includes a right rocker arm 4 hinged on the shearer body 1 through a hinge shaft, a right drum 5 installed at the front end of the right rocker arm 4, and a drive for driving the right drum 5. Right cutting motor, the right drum 5 is in transmission connection with the right cutting motor; the left rocker arm 2 is in transmission connection with the left height adjustment oil cylinder, and the right rocker arm 4 is in transmission connection with the right height adjustment oil cylinder; The lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com