A preparation method of activated carbon catalyst for flue gas desulfurization and denitrification

A desulfurization and denitrification, activated carbon technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of high price, no mention of desulfurization efficiency, complicated preparation methods, etc., and achieve good removal rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

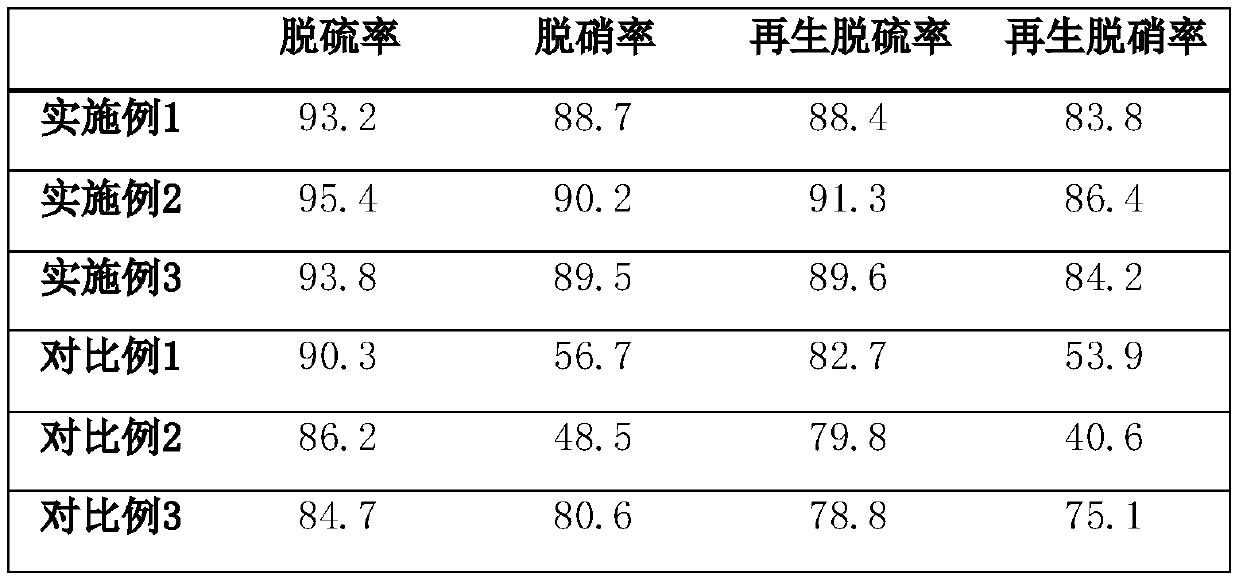

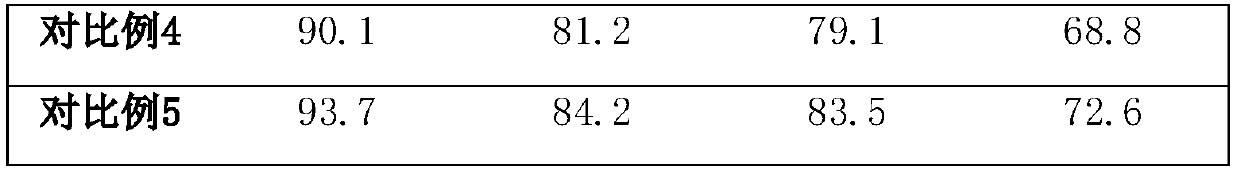

Examples

Embodiment 1

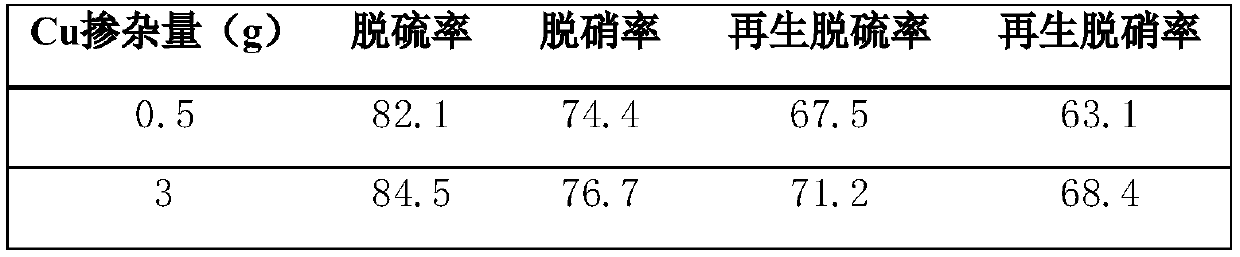

[0025] Supported Cu-doped TiO 2 Preparation of activated carbon catalyst:

[0026] (1) Dissolve 10ml of tetrabutyl titanate in 35ml of absolute ethanol, stir magnetically for 10min, and mix well to form a yellow clear solution A. Add 1.1g of copper nitrate, 10ml of distilled water and 4ml of glacial acetic acid into 35ml of absolute ethanol, and stir vigorously To obtain solution B, slowly add solution B to solution A at a rate of 3ml / min, continue to stir for 30 minutes after the addition, heat in a water bath at 40°C for 2 hours to obtain a gel, and place it in a muffle furnace for drying at 80°C Dry for 20 hours to obtain a xerogel, grind it into a fine powder in an agate mortar, and calcinate the fine powder at 500°C for 1 hour to obtain Cu-doped TiO 2 Powder;

[0027] (2) Activated carbon supported Cu doped TiO 2 : Take the 5g Cu-doped TiO obtained in step (1) 2 Add the powder, 2ml of tetraethyl orthosilicate and 1ml of polyethylene glycol to 20ml of water to obtain a...

Embodiment 2

[0031] Supported Cu-doped TiO 2 Preparation of activated carbon catalyst:

[0032] (1) Dissolve 10ml of tetrabutyl titanate in 35ml of absolute ethanol, stir magnetically for 10min, and mix well to form a yellow clear solution A. Add 2.66g of copper nitrate, 10ml of distilled water and 4ml of glacial acetic acid into 35ml of absolute ethanol, and stir vigorously To obtain solution B, slowly add solution B to solution A at a rate of 3ml / min, continue to stir for 30 minutes after the addition, heat in a water bath at 40°C for 2 hours to obtain a gel, and place it in a muffle furnace for drying at 80°C Dry for 24 hours to obtain a xerogel, grind it into a fine powder in an agate mortar, and calcinate the fine powder at 800°C for 1.5 hours to obtain Cu-doped TiO 2 .

[0033] (2) TiO doped with Cu supported on activated carbon 2 : Take the 5g Cu-doped TiO obtained in step (1) 2 Powder, add it with 2ml tetraethyl orthosilicate and 1ml polyethylene glycol into 20ml water, soak ac...

Embodiment 3

[0037] Supported Cu-doped TiO 2 Preparation of activated carbon catalyst:

[0038] (1) Dissolve 10ml of tetrabutyl titanate in 35ml of absolute ethanol, stir magnetically for 10min, and mix well to form a yellow clear solution A. Add 1.35g of copper chloride, 10ml of distilled water and 4ml of glacial acetic acid into 35ml of absolute ethanol, and vigorously Stir to obtain solution B, slowly add solution B to solution A dropwise at a rate of 3ml / min, continue stirring for 30min after the dropwise addition, heat in a water bath at 40°C for 2h to obtain a gel, and place it in a muffle furnace at 80°C Dry for 20 hours to obtain xerogel, grind it into a fine powder in an agate mortar, and calcinate the fine powder at 600°C for 1 hour to obtain Cu-doped TiO 2 .

[0039] (2) TiO doped with Cu supported on activated carbon 2 : Take the 5g Cu-doped TiO obtained in step (1) 2 powder, add it with 2ml tetraethyl orthosilicate and 1ml polyethylene glycol to 20ml water to obtain a solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com