Five-nature compatible served natural fruit enzyme and preparation method thereof

A kind of fruit enzyme and fruit technology, applied in the function of food ingredients, food science, application, etc., can solve the problems such as the report of the compatibility of the five natures of fruit enzymes that have not been seen in the table, so as to improve human immunity, improve skin diseases, and improve digestion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A natural fruit enzyme that is compatible with five properties, prepared from the following components by mass fraction: flat fruit 61.6%; cold fruit 9.6%; cool fruit 9.6%; warm fruit 9.6%; hot fruit 9.6% %.

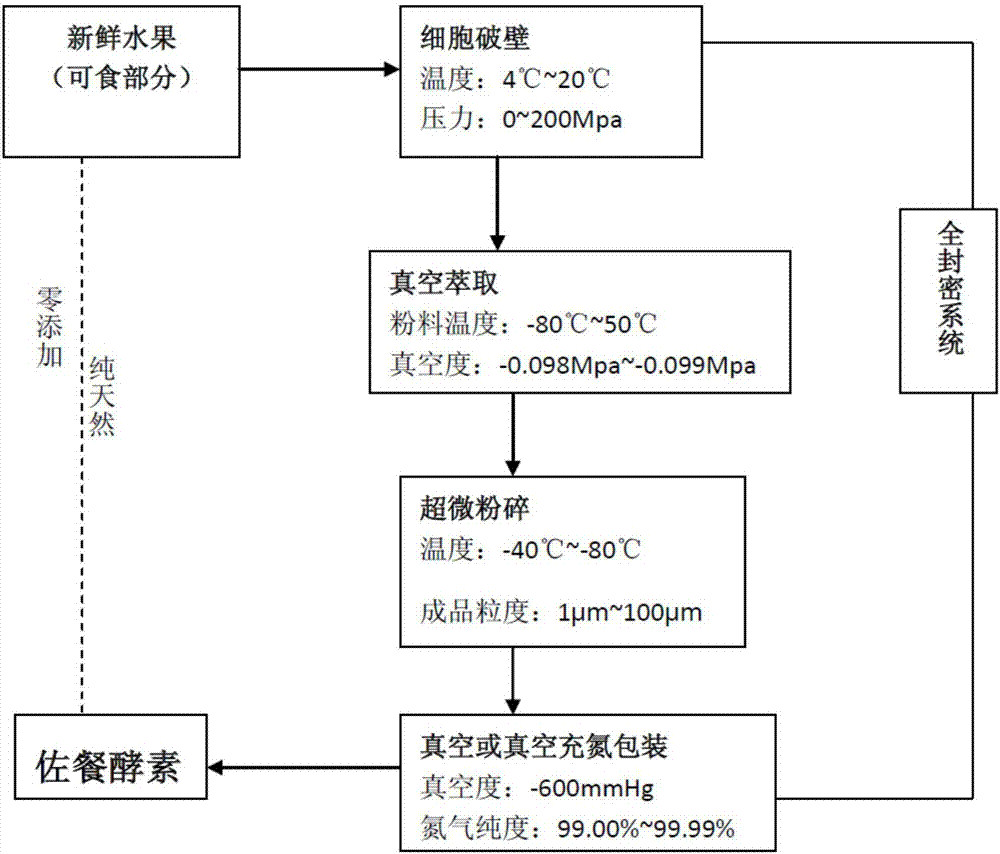

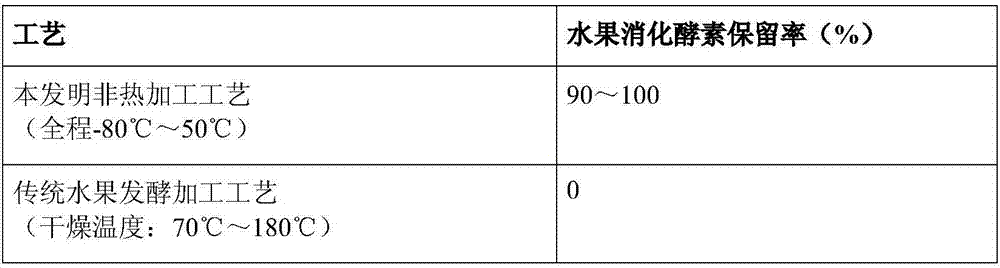

[0048] The schematic diagram of the preparation process is shown in figure 1 , the preparation method is as follows: the edible part of the flat fruit is prepared into a pulp, which is continuously sent to a low-temperature and high-pressure wall breaker at 4-20°C and a pressure of 0-200MPa for 1-20 minutes of wall-breaking treatment, and the wall-breaking rate reaches 90%. above. The broken material is placed in a vacuum belt dryer at -80 to 50°C and a vacuum of -0.098 to -0.099 MPa and continuously vacuumed until the water content is less than or equal to 5%. Then, the dried food is processed in a low-temperature ultrafine pulverizer at -40 to -80°C to obtain a powder with a particle size of 10 to 100 μm;

[0049] Make cold fruit, cool fruit, warm fruit, and ...

Embodiment 2

[0064] A natural fruit enzyme with compatibility of five properties is prepared from components with the following mass fractions: flat fruit 61.6%, cool fruit 19.2% and warm fruit 19.2%.

[0065] The preparation method is as follows: the edible part of the flat fruit is prepared into a pulp, which is continuously sent to a low-temperature high-pressure wall breaker at 4-20°C and a pressure of 0-200MPa for 1-20 minutes of wall-breaking treatment, and the wall-breaking rate reaches more than 90%. . The broken material is placed in a vacuum belt dryer at -80 to 50°C and a vacuum of -0.098 to -0.099 MPa and continuously vacuumed until the water content is less than or equal to 5%. Then, the dried food is processed in a low-temperature ultrafine pulverizer at -40 to -80°C to obtain a powder with a particle size of 10 to 100 μm;

[0066] Make cool fruit and warm fruit into powder according to the above preparation method, mix them, and use vacuum or vacuum nitrogen filling packagi...

Embodiment 3

[0068] A natural fruit enzyme that is compatible with five properties is prepared from the following components in mass fraction: flat fruit 61.6%, cold fruit 19.2% and hot fruit 19.2%.

[0069] The preparation method specifically comprises: preparing a pulp from the edible part of the flat fruit, and continuously feeding it into a low-temperature, high-pressure wall breaking machine at 4-20° C. and a pressure of 0-200 MPa for 1-20 minutes of wall-breaking treatment. The broken material is placed in a vacuum belt dryer at -80 to 50°C and a vacuum of -0.098 to -0.099 MPa and continuously vacuumed until the water content is less than or equal to 5%. Then, the dried food is processed in a low-temperature ultrafine pulverizer at -40 to -80°C to obtain a powder with a particle size of 10 to 100 μm;

[0070] Make cold fruit and hot fruit into powder according to the above preparation method, mix them, and use vacuum or vacuum nitrogen filling packaging technology to pack at a vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com